What Is a Mining Impact Crusher?

How Does a Mining Impact Crusher Work?

Material Feeding: Crushed rocks or ores (from primary crushers like jaw crushers) are uniformly fed into the mining impact crusher via a vibrating feeder.

High-Speed Impact: The crusher’s rotor rotates at 800-1500 rpm, accelerating the hammerheads/blow bars to high velocity. As materials enter the chamber, they are struck by the rotating components, breaking into smaller fragments.

Secondary Crushing: The fragmented material rebounds off the rotor and collides with fixed anvils or the chamber’s lining—creating a “particle-on-particle” crushing effect that refines particle shape.

Screening & Classification: Qualified particles (typically 0-20mm) are discharged through a built-in vibrating screen. Oversize materials are recycled back to the crushing chamber for reprocessing, ensuring uniform output.

Key Types of Mining Impact Crushers

1. Horizontal Shaft Impact Crusher (HSI) for Mining

Large feed opening to handle bulky materials.

Adjustable discharge settings for precise particle size control.

Excellent particle shaping (cubical output with low flakiness rate ≤10%).

Suitable for processing limestone, dolomite, and soft-to-medium hard ores.

2. Vertical Shaft Impact Crusher (VSI) for Mining

High-speed rotor (1500-3000 rpm) for fine crushing and shaping.

Particle-on-particle crushing for superior cubical shape (flakiness rate ≤5%).

Ideal for hard ores like granite, basalt, and gold/copper ore tailings.

Energy-efficient operation with low wear rates on components.

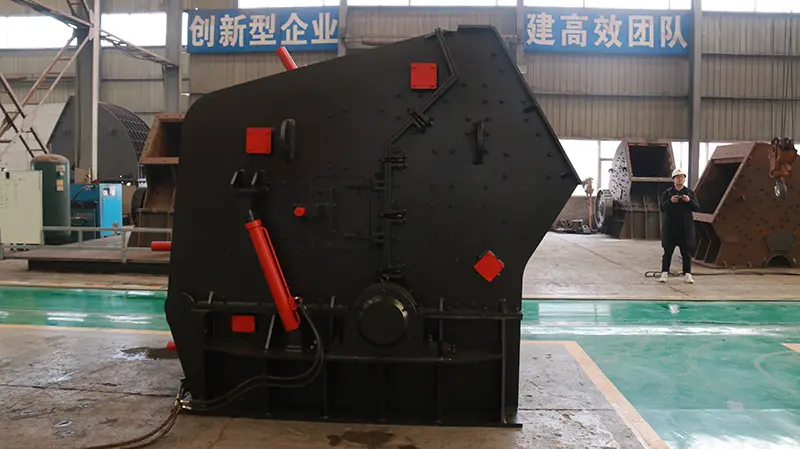

Core Features of a High-Quality Mining Impact Crusher

Wear-Resistant Components: Blow bars, hammerheads, and anvils are made of high-chromium alloy steel or carbide materials, resisting abrasion from hard rocks.

Adjustable Impact Force: Hydraulic or mechanical systems allow operators to adjust rotor speed and anvil position, adapting to different material hardness and particle size requirements.

Robust Structure: Reinforced frame and rotor design withstands dynamic loads and vibration during high-capacity operation.

Safety Systems: Overload protection, emergency stop buttons, and protective guards prevent equipment damage and ensure worker safety.

Intelligent Control: PLC control systems with real-time monitoring of rotor speed, feed rate, and wear levels—enabling automated operation and predictive maintenance.

Easy Maintenance: Modular design and side-access doors simplify wear part replacement and inspection, minimizing downtime.

Industrial Applications of Mining Impact Crushers

Hard Rock Mining: Processes granite, basalt, quartz, and diabase for road construction, railway ballast, and concrete aggregates.

Metal Ore Mining: Crushes gold, copper, iron, and zinc ores in secondary/tertiary stages, facilitating mineral separation (flotation, magnetic separation).

Quarrying Operations: Produces graded aggregates for construction projects, including bridges, dams, and buildings.

Construction Waste Recycling: Converts demolished concrete, asphalt, and brick into recycled aggregates—promoting environmental sustainability.

Mineral Processing Plants: Shapes ore tailings into usable materials, reducing waste and creating additional revenue streams.

Key Advantages of Using a Mining Impact Crusher

Superior Particle Shape: Cubical output improves aggregate quality, enhancing the strength and workability of concrete and asphalt.

High Crushing Efficiency: Impact-based crushing requires less energy than compression crushing for medium-hard materials, lowering operational costs.

Wide Material Adaptability: Handles diverse ores and rocks, from soft limestone to hard granite—no need for multiple specialized crushers.

High Throughput: Large feed capacity and fast processing speeds meet the demands of large-scale mining operations (up to 1500 TPH for industrial models).

Flexible Configuration: Available as stationary, mobile, or portable units, adapting to different site conditions and production needs.

How to Choose the Right Mining Impact Crusher?

Material Hardness: Choose HSI for medium-hard materials (Mohs hardness 5-7) and VSI for hard ores (Mohs hardness 7-9).

Production Capacity: Match the crusher’s throughput (50-1500 TPH) to your daily output requirements.

Particle Size Requirements: Ensure the crusher can produce the target particle size (0-10mm, 10-20mm) for your application.

Wear Part Durability: Prioritize models with high-chromium or carbide wear parts for abrasive materials.

Mobility Needs: Opt for a mobile mining impact crusher if you require on-site crushing or frequent relocation.

Manufacturer Support: Partner with a reputable supplier offering genuine parts, on-site installation, and 24/7 technical support.