Heavy hammer crushers are vital equipment in mining, construction, and aggregate production, known for their ability to process large, hard materials in single-stage crushing. To fully leverage their performance, understanding the hammer crusher working principle is essential. Unlike cone or jaw crushers that rely on compression, the hammer crusher working principle centers on high-speed impact—using rotating hammers to break down rocks, ores, and construction waste. This guide explains the core mechanics, key components, operational steps, and factors influencing the hammer crusher working principle, providing clarity for industry professionals and equipment buyers.

At its heart, the hammer crusher working principle is based on impact crushing—converting rotational energy into kinetic force to fracture materials. A heavy hammer crusher features a horizontal rotor fitted with multiple hammerheads (or blow bars) that rotate at high speed (800-1500 rpm). When materials enter the crushing chamber, they collide with the rotating hammerheads, breaking into smaller fragments. The fragmented material then rebounds off the chamber’s counterattack plates (or impact liners) for secondary crushing, before passing through a discharge screen to separate qualified particles from oversize material (which is recycled for reprocessing). This single-stage, high-impact process is what makes the hammer crusher efficient for medium-to-hard materials like limestone, granite, and coal.

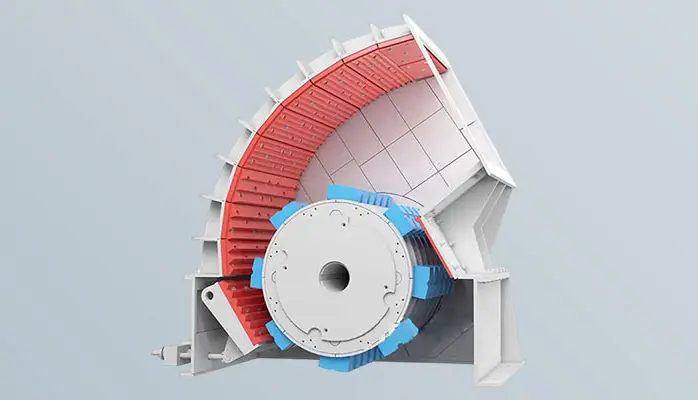

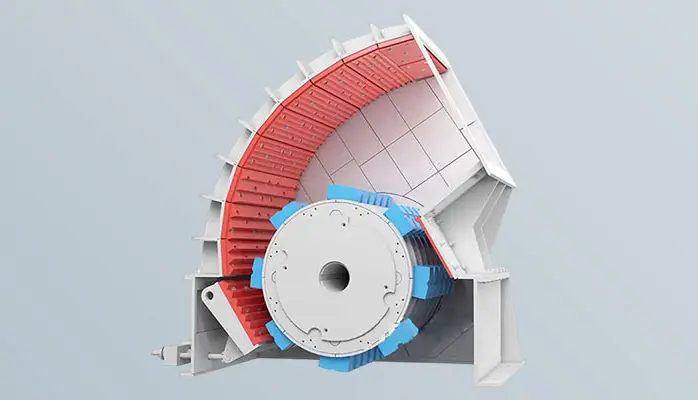

The hammer crusher working principle relies on coordinated operation of several critical components—each playing a role in delivering impact force and ensuring consistent crushing:

Rotor: The core rotating component, typically made of high-strength steel. It’s mounted on a robust shaft and driven by a high-power motor, providing the rotational energy for hammerheads.

Hammerheads: Wear-resistant components (made of high-chromium alloy or manganese steel) attached to the rotor. Their shape (flat, curved, or clawed) and arrangement optimize impact force for different materials.

Counterattack Plates: Stationary steel plates lining the crushing chamber. They redirect rebounding material for secondary impact, refining particle size and shape.

Discharge Screen: A grid or perforated plate at the bottom of the chamber. It controls the final product size—only particles smaller than the screen openings are discharged.

Feeding System: A vibrating feeder or hopper that delivers materials uniformly into the crushing chamber, preventing overload and ensuring stable operation.

Safety Devices: Overload protection (e.g., hydraulic cylinders) and protective guards prevent equipment damage from uncrushable objects (like tramp iron) and ensure worker safety.

The hammer crusher working principle unfolds in four sequential stages, ensuring efficient and thorough crushing:

Material Feeding: Bulk materials (up to 500mm in size) are fed into the crushing chamber via the feeding system. Uniform feeding is critical—overloading can stall the rotor, while uneven feeding reduces crushing efficiency.

Primary Impact Crushing: The rotor rotates at high speed, accelerating the hammerheads. As materials enter the chamber, they are struck by the hammerheads with immense kinetic force, breaking into small fragments (typically 50-100mm).

Secondary Impact & Refining: The fragmented material rebounds off the hammerheads and collides with the counterattack plates. This secondary impact further reduces particle size and improves shape (making it more cubical).

Screening & Discharge: Qualified particles (matching the discharge screen’s opening size, e.g., 0-20mm) fall through the screen and are collected. Oversize particles are retained in the chamber, where they are repeatedly struck by hammerheads until they meet the size requirement—ensuring no waste.

This continuous cycle is what defines the hammer crusher working principle, enabling single-stage crushing that eliminates the need for secondary crushers in many applications.

Several variables affect the efficiency and output of the hammer crusher working principle, requiring careful adjustment for optimal performance:

Rotor Speed: Higher rotor speed increases impact force, ideal for hard materials (e.g., granite). Lower speed is suitable for softer materials (e.g., limestone) to reduce wear on hammerheads.

Hammerhead Design: Curved hammerheads deliver more concentrated impact, while flat hammerheads distribute force evenly—choose based on material hardness and particle size goals.

Screen Opening Size: Larger openings produce coarser output (e.g., 20-40mm for road base), while smaller openings yield finer particles (e.g., 0-5mm for concrete sand).

Material Properties: The hammer crusher working principle performs best with materials of Mohs hardness 5-8. Extremely hard materials (e.g., basalt) may require reinforced hammerheads or a two-stage crushing process.

Feeding Uniformity: Uneven feeding causes rotor imbalance and inconsistent crushing—using a vibrating feeder ensures steady material flow.

Understanding how the hammer crusher working principle differs from other crushers helps in selecting the right equipment:

vs. Jaw Crusher: Jaw crushers use compression crushing for primary processing of large materials. The hammer crusher working principle (impact-based) enables single-stage crushing of large feed into fine output, reducing equipment costs.

vs. Cone Crusher: Cone crushers rely on compression for secondary crushing of hard materials. Hammer crushers offer higher throughput and better particle shape but are less durable for ultra-hard ores.

vs. Impact Crusher: While both use impact, hammer crushers have fixed hammerheads and a single rotor, making them simpler and more cost-effective for medium-hard materials. Impact crushers (HSI/VSI) have adjustable anvils and better shaping for aggregates.

The efficiency of the hammer crusher working principle makes it ideal for diverse industrial scenarios:

Mining: Crushes coal, iron ore, and limestone in primary or secondary stages, facilitating mineral processing.

Construction Aggregates: Produces concrete sand, road base, and railway ballast from granite, basalt, and river pebbles.

Construction Waste Recycling: Converts demolished concrete, brick, and asphalt into recycled aggregates—supporting sustainability.

Cement Manufacturing: Processes limestone and clay into raw material for cement production, ensuring uniform particle size for grinding.

Chemical Industry: Crushes gypsum, phosphate rock, and other chemical raw materials for further processing.

The

hammer crusher working principle—rooted in high-speed impact and single-stage crushing—delivers efficiency, simplicity, and cost-effectiveness for mining, construction, and aggregate operations. By understanding its core mechanics, key components, and influencing factors, businesses can optimize their crushing processes, reduce operational costs, and achieve consistent product quality.

Whether processing coal, limestone, or construction waste, the hammer crusher’s working principle adapts to diverse materials and production needs. As technology evolves, modern hammer crushers integrate intelligent controls (e.g., rotor speed adjustment) and wear-resistant materials, enhancing the reliability of the hammer crusher working principle.

For anyone selecting a hammer crusher, a clear grasp of its working principle is the first step to choosing the right model. Partner with a reputable manufacturer to ensure your equipment is engineered to maximize the hammer crusher working principle’s potential—delivering long-term performance and value.