Core Advantages of Flotation Machines

High Mineral Recovery Rate: One of the most prominent advantages of flotation machines is their ability to achieve high recovery rates of valuable minerals. By precisely controlling factors like reagent dosage, air flow, and agitation intensity, flotation machines can effectively separate even fine-grained minerals (down to 10 μm) from gangue. This is particularly valuable for low-grade ore deposits, where maximizing the extraction of valuable minerals directly improves the economic efficiency of mining operations. For example, in copper, lead-zinc, and gold mining, flotation machines often achieve recovery rates above 90% for target minerals.

Strong Versatility for Diverse Materials: Flotation machines exhibit excellent versatility, capable of processing a wide range of minerals and materials. They are not limited to specific mineral types—whether non-ferrous metals (copper, lead, zinc), precious metals (gold, silver), non-metallic minerals (fluorite, barite), or even coal. Additionally, they can handle ores with different particle sizes, from coarse aggregates to fine slimes, by adjusting operational parameters. This versatility makes flotation machines a core piece of equipment in multi-mineral mines and complex ore processing plants.

Efficient Separation of Complex Ores: For complex ores (e.g., polymetallic ores containing multiple valuable minerals, or ores with fine-grained mineral dissemination), flotation machines demonstrate unparalleled separation efficiency. Through sequential flotation (e.g., priority flotation, bulk flotation, or reverse flotation), they can separate different valuable minerals one by one, achieving effective enrichment of each target mineral. This advantage is difficult to replicate by other separation methods (such as gravity separation or magnetic separation), making flotation machines indispensable for processing complex ore bodies.

Flexible Operational Adjustability: Flotation machines offer high flexibility in operation, allowing operators to adjust key parameters in real time according to ore properties and process requirements. Critical parameters like air flow rate, agitation speed, pulp concentration, and reagent dosage can be fine-tuned to optimize separation effects. For example, when processing ores with varying mineral content, operators can quickly adjust reagent addition to maintain stable recovery rates. This flexibility ensures that flotation machines can adapt to fluctuations in raw material quality, guaranteeing consistent production efficiency.

Energy Efficiency & Low Operational Costs: Modern flotation machines are designed with energy-saving features that reduce operational costs. Advanced agitation systems (e.g., low-power impellers) and air distribution technologies minimize energy consumption while maintaining effective bubble-mineral contact. Additionally, the modular design of flotation machines simplifies maintenance—parts are easy to replace, and routine inspections require minimal labor. Compared to other high-intensity separation equipment, flotation machines have lower long-term operational and maintenance costs, enhancing the overall economic benefits of processing plants.

Compatibility with Automated Control Systems: Another key advantage of flotation machines is their compatibility with modern automated control systems. Sensors installed in flotation cells can monitor real-time data such as pulp level, bubble size, and mineral grade. This data is transmitted to a central control system, which automatically adjusts operational parameters (e.g., air flow, reagent dosage) to maintain optimal separation conditions. Automation not only reduces the reliance on manual operation but also improves process stability and reduces human error, further boosting production efficiency and product quality.

Effective Handling of Fine-Grained Minerals: Many mineral deposits exist in fine-grained forms, which are difficult to separate using traditional methods. Flotation machines excel at handling fine and ultra-fine particles because their bubble attachment mechanism is not overly dependent on particle size—instead, it relies on surface chemistry. By using appropriate collectors and frothers, flotation machines can effectively capture fine-grained valuable minerals, unlocking the economic potential of low-grade, fine-grained ore deposits that would otherwise be unprofitable to process.

Advantages of Different Types of Flotation Machines for Specific Scenarios

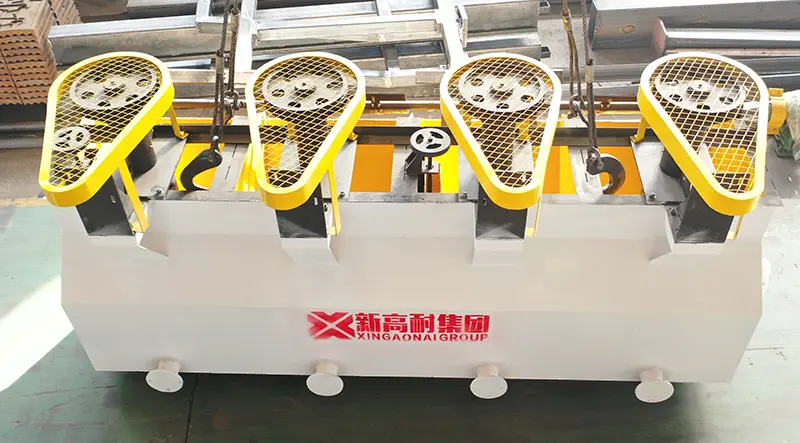

Mechanical Flotation Machines: The most widely used type, featuring strong agitation capacity. Their advantage lies in stable operation and adaptability to high-pulp-density ores, making them ideal for large-scale mineral processing plants.

Pneumatic Flotation Machines: Rely on compressed air for bubble generation, eliminating the need for a mechanical impeller. Their key advantages include low energy consumption, low noise, and suitability for corrosive or explosive environments (e.g., processing of sulfide ores with flammable reagents).

Column Flotation Machines: Characterized by a tall, cylindrical structure. Their advantage is high separation precision, especially for removing fine gangue from valuable minerals, making them suitable for upgrading low-grade concentrates and processing fine-grained ores.

Circulating Flotation Machines: Equipped with a circulation system for pulp, their advantage is efficient utilization of reagents and air, reducing material waste and improving overall process efficiency for low-grade ores.

How the Advantages of Flotation Machines Support Industrial Applications

Mining Industry: In non-ferrous metal, precious metal, and coal mining, the high recovery rate and versatility of flotation machines ensure maximum extraction of valuable resources. For example, in gold mining, flotation machines separate gold-bearing sulfide minerals from gangue, laying the foundation for subsequent gold extraction processes (e.g., cyanidation).

Chemical Industry: Flotation machines are used to separate and purify chemical raw materials, such as separating salts from brine or purifying industrial minerals (e.g., kaolin). Their precise separation capacity ensures the purity of chemical products, meeting high-quality production requirements.

Wastewater Treatment: In wastewater treatment plants, flotation machines (specifically dissolved air flotation machines) separate suspended solids, oil, and other pollutants from water. Their high separation efficiency helps meet environmental discharge standards, supporting green production.

Recycling Industry: Flotation machines play a role in recycling valuable materials from industrial waste, such as recovering metals from electronic waste or plastic particles from composite materials. Their versatility and fine-particle handling capacity contribute to resource recycling and circular economy development.