Why Choosing the Right Vibrating Feeder Manufacturers Matters

Equipment Durability: Industrial environments demand feeders that withstand abrasive materials, continuous operation, and harsh conditions. Leading vibrating feeder manufacturers use high-grade steel, wear-resistant components, and robust designs to ensure long service life.

Custom Adaptability: Every project has unique needs (material type, capacity, site constraints). Reliable vibrating feeder manufacturers offer custom configurations instead of one-size-fits-all models.

Operational Efficiency: Well-engineered feeders from reputable vibrating feeder manufacturers reduce energy consumption, minimize material spillage, and ensure consistent feeding—cutting operational costs.

After-Sales Support: Industrial equipment requires maintenance and technical assistance. Top vibrating feeder manufacturers provide timely service, spare parts, and training to keep your operations running.

Compliance & Safety: Trusted manufacturers adhere to global safety and environmental standards (CE, ISO 9001, EPA), ensuring your equipment meets regulatory requirements.

Core Product Offerings from Leading Vibrating Feeder Manufacturers

1. Electromagnetic Vibrating Feeder

Design & Principle: Uses electromagnetic force to generate vibration, enabling precise control of feeding speed (0-100 TPH). Ideal for fine or lightweight materials (powder, small granules).

Key Features: Adjustable amplitude, low energy consumption, quiet operation (≤75 dB), and no mechanical wear.

Ideal Applications: Chemical plants, cement production, and fine ore processing—trusted by vibrating feeder manufacturers for its precision.

2. Motor-Driven Vibrating Feeder

Design & Principle: Powered by a vibration motor, delivering high amplitude for heavy-duty feeding of large, abrasive materials (boulders, ore chunks).

Key Features: High capacity (50-1000 TPH), durable construction, and adaptability to rough working conditions.

Ideal Applications: Mining, quarries, and construction sites—core product for vibrating feeder manufacturers serving heavy industries.

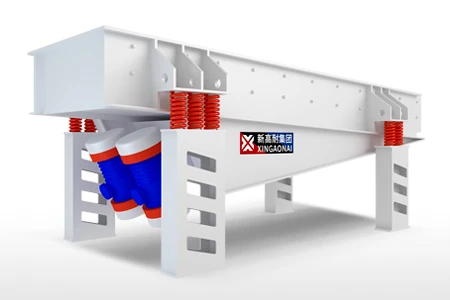

3. Linear Vibrating Feeder

Design & Principle: Produces linear vibration to transport materials in a straight line, ensuring uniform feeding to downstream equipment.

Key Features: Stable operation, easy maintenance, and compatibility with crushers/screens.

Ideal Applications: Aggregate production lines, coal handling, and recycling plants.

4. Circular Vibrating Feeder

Design & Principle: Generates circular vibration for efficient feeding of irregularly shaped materials, reducing clogging risks.

Key Features: High throughput, anti-blocking design, and suitability for wet or sticky materials.

Ideal Applications: Quarries, hydraulic engineering, and construction waste recycling.

5. Heavy-Duty Vibrating Feeder

Design & Principle: Reinforced frame, thickened wear plates, and high-power motors for extreme conditions (large ore, continuous 24/7 operation).

Key Features: Capacity up to 2000 TPH, impact-resistant components, and long service intervals.

Ideal Applications: Large-scale mines, iron ore processing, and bulk material terminals—flagship product for specialized vibrating feeder manufacturers.

Core Advantages of Top Vibrating Feeder Manufacturers

1. Engineering Expertise & R&D Capabilities

2. Customization Capabilities

Analyze material properties (abrasiveness, moisture content, particle size).

Design feeders matching production capacity (5-2000 TPH) and site constraints (space, layout).

Integrate auxiliary features (dust covers, anti-spill edges, automatic lubrication systems).

3. Quality Control & Durability

Use high-grade materials (manganese steel wear plates, stainless steel frames for corrosion resistance).

Conduct load-bearing, vibration, and durability tests before delivery.

Ensure components (motors, bearings, springs) meet industrial-grade standards.

4. Global Service Network

On-site installation and commissioning by professional technicians.

Operator training on safety, operation, and basic maintenance.

24/7 technical support and fast delivery of genuine spare parts.

Long-term maintenance contracts to extend equipment life.

5. Environmental & Safety Compliance

Low-noise operation and dust-proof covers to meet environmental regulations.

Emergency stop buttons, overload protection, and safety guards to prevent accidents.

Energy-efficient motors (IE3/IE4) to reduce carbon footprint.

How to Select the Best Vibrating Feeder Manufacturers for Your Project

Industry Experience: Choose manufacturers with 10+ years of experience in your sector (e.g., mining-specific manufacturers for ore feeding needs).

Product Quality & Certifications: Verify ISO 9001 quality management certification and compliance with regional standards (CE for Europe, FDA for food-related industries).

Customization Capacity: Ensure they can design feeders tailored to your material type, capacity, and site conditions.

After-Sales Support: Confirm availability of on-site service, spare parts, and technical assistance in your region.

Customer Reviews & Case Studies: Check testimonials from clients in similar industries and review successful project case studies.

Pricing & Value: Avoid choosing based solely on low cost—prioritize value (durability, efficiency, service) for long-term savings.