River sand is a vital raw material in construction, concrete production, and infrastructure projects, valued for its natural granularity and stability. However, raw river sand often contains impurities like mud, dust, stone chips, and organic matter that compromise the strength and durability of finished products. A river sand washing machine is a specialized industrial equipment designed to clean and purify river sand, removing unwanted contaminants to meet strict construction and aggregate standards. Whether for small quarries or large-scale construction sites, a high-quality river sand washing machine ensures consistent, clean sand output—critical for optimizing project quality and efficiency.

What Is a River Sand Washing Machine? Core Definition & Purpose

Remove soluble salts, organic matter, and fine dust that weaken concrete strength.

Separate stone chips and oversized particles to meet aggregate grading requirements.

Improve sand cleanliness (impurity content ≤1%) for high-grade construction projects.

Reduce material waste by retaining usable sand while flushing out contaminants.

How Does a River Sand Washing Machine Work?

Feeding: Raw river sand is evenly fed into the machine via a vibrating feeder or belt conveyor.

Agitation & Washing: Inside the machine, sand is agitated by rotating impellers, spiral blades, or wheel buckets. High-pressure water jets flush the sand, loosening and separating mud and dust from the sand grains.

Impurity Separation: Contaminants (mud, dust, fine particles) are carried away by water to a sedimentation tank, while clean sand remains in the washing chamber.

Dehydration & Discharging: Clean sand is dewatered via screen mesh or centrifugal force, reducing moisture content (≤15%) before being discharged as finished product. The water can be recycled after sedimentation, minimizing waste.

Common Types of River Sand Washing Machine

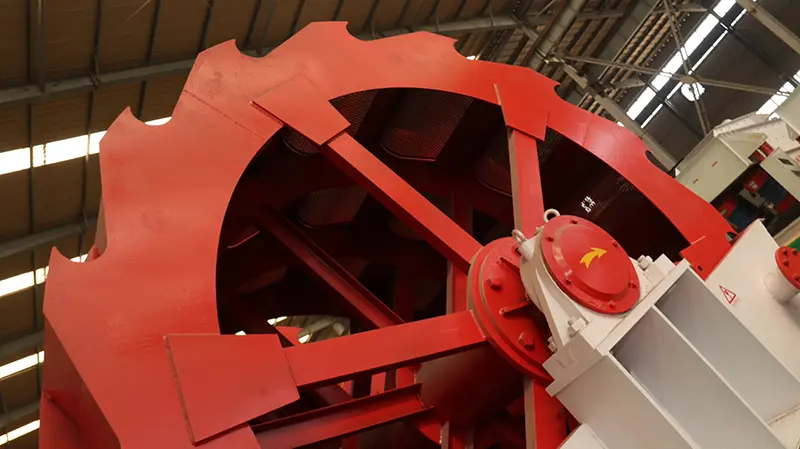

1. Wheel Type River Sand Washing Machine

Features a rotating wheel bucket with impellers that scoop and wash sand.

Advantages: Low energy consumption, simple structure, easy maintenance, and gentle washing (avoids sand grain breakage).

Ideal for: Small-to-medium quarries, construction sites, and concrete plants processing 50-300 TPH of river sand.

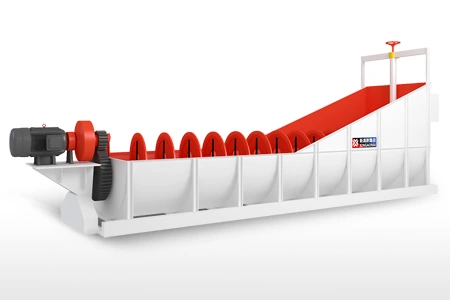

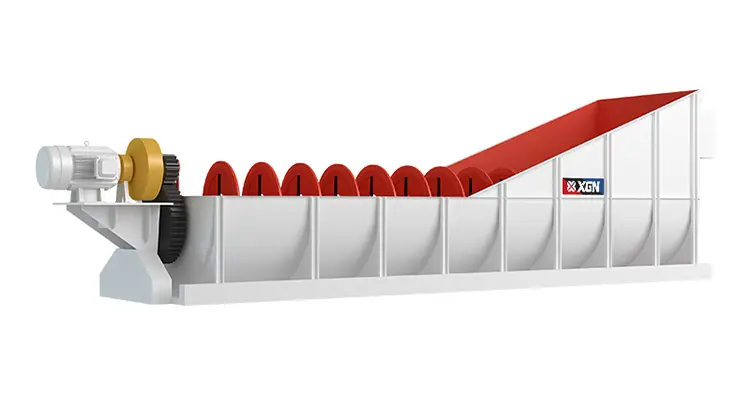

2. Spiral River Sand Washing Machine

Uses spiral blades to agitate and transport sand, with a deep washing chamber for thorough cleaning.

Advantages: High impurity removal rate (≥95%), large capacity (100-800 TPH), and strong adaptability to muddy sand.

Ideal for: Large-scale aggregate production lines, mines, and industrial sand processing facilities.

3. Portable River Sand Washing Machine

Mounted on a tracked or wheeled chassis for on-site cleaning and flexible relocation.

Advantages: Eliminates sand transportation costs, quick deployment (set up in hours), and compact design for space-constrained sites.

Ideal for: Temporary construction projects, remote quarries, and construction waste recycling (cleaning recycled sand from concrete debris).

Core Features of a High-Quality River Sand Washing Machine

High Cleaning Efficiency: Advanced impeller/spiral design ensures thorough impurity removal, with clean sand output meeting GB/T 14684-2022 and ASTM C33 standards.

Water-Saving Design: Closed-loop water recycling system reduces water consumption by 60-70% compared to traditional washing methods, complying with environmental regulations.

Durable Construction: Wear-resistant manganese steel impellers, stainless steel screen mesh, and corrosion-resistant frame withstand abrasive river sand and wet working conditions.

Automatic Operation: PLC control system with adjustable washing time and water pressure, enabling remote monitoring and reducing labor costs.

Low Noise & Vibration: Balanced mechanical structure and shock-absorbing components ensure quiet operation (≤85 dB), suitable for urban construction sites.

Easy Maintenance: Removable impellers, accessible screen mesh, and modular design simplify cleaning and part replacement, minimizing downtime.

Application Scenarios of River Sand Washing Machine

Construction Industry: Cleans river sand for concrete mixing, brick making, and building foundations—enhancing structural strength and durability.

Highway & Railway Construction: Provides clean sand for asphalt pavements, road bases, and railway ballast—improving load-bearing capacity and wear resistance.

Concrete & Precast Production: Supplies high-purity sand for ready-mix concrete, precast components, and high-rise building construction.

Quarry & Aggregate Production: Processes natural river sand into graded aggregates for commercial sale, meeting market quality demands.

Construction Waste Recycling: Cleans recycled sand from crushed concrete, brick, and demolition waste, reducing resource waste and environmental impact.

How to Choose the Right River Sand Washing Machine?

Production Capacity: Choose wheel type (50-300 TPH) for small-scale needs, spiral type (100-800 TPH) for large-scale production, or portable type for flexible output.

Sand Impurity Content: Spiral type for high-mud sand (impurity content ≥5%), wheel type for low-mud sand (impurity content ≤3%).

Application & Mobility: Portable type for on-site or temporary projects; stationary wheel/spiral type for fixed production lines.

Environmental Requirements: Prioritize water-saving models with recycling systems for regions with strict water usage regulations.