Core Working Process of Stone Crusher Sand Making Machine

Primary Crushing: Raw stone (0-1000mm) is fed into a jaw crusher via a vibrating feeder for coarse crushing, reducing particles to 100-200mm.

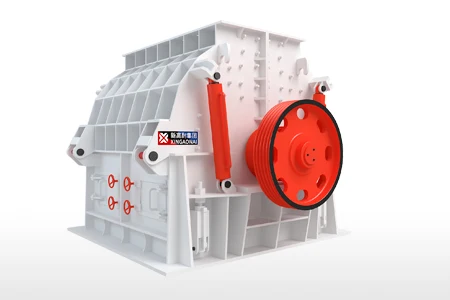

Secondary Crushing: Coarsely crushed stone is sent to a cone crusher or impact crusher for fine crushing, achieving particle size of 10-20mm.

Sand Making (Shaping): The fine-crushed stone enters the core sand making machine (vertical shaft impact crusher is mainstream). High-speed rotating impellers throw materials against the crushing chamber, forming "stone-on-stone" or "stone-on-iron" impact to crush and shape particles into cubic sand with uniform gradation.

Screening & Classification: A vibrating screen separates qualified sand (0.15-5mm) from oversized particles. Unqualified materials are recycled back to the sand making machine for reprocessing.

Washing (Optional): For high-purity sand needs, a sand washing machine removes dust and impurities from the finished sand, improving its cleanliness and quality for concrete production.

Key Components of a Reliable Stone Crusher Sand Making Machine

Crushing Equipment: Jaw crusher (primary crushing), cone/impact crusher (secondary crushing) for reducing stone size.

Sand Making Host: Vertical shaft impact crusher (VSI) for shaping and fine crushing, ensuring cubic particle shape.

Screening Equipment: Circular vibrating screen for precise grading of finished sand and recycled materials.

Feeding & Conveying Equipment: Vibrating feeder (uniform feeding), belt conveyor (material transportation between components).

Washing Equipment: Sand washing machine (optional) for impurity removal, enhancing sand quality.

Control System: PLC automated control panel for adjusting speed, feeding rate, and screening parameters, ensuring stable operation.

Core Advantages of Stone Crusher Sand Making Machine

High Efficiency & Output: Integrates crushing, shaping, and screening in one system, with production capacity ranging from 50-500 TPH to meet diverse project scales.

Superior Sand Quality: Produces artificial sand with uniform gradation, cubic particle shape, and adjustable fineness modulus (2.3-3.1), meeting national construction sand standards.

Energy & Cost Saving: Equipped with energy-efficient motors and optimized crushing cavity design, reducing power consumption by 15-20% compared to traditional equipment.

Strong Adaptability: Handles various hard stones (Mohs hardness 5-10) such as granite, basalt, limestone, and river rock.

Durable & Low Maintenance: Wear-resistant components (manganese steel liners, impeller parts) extend service life; accessible structure simplifies maintenance and reduces downtime.

Environmental Compliance: Equipped with dust suppression and noise reduction systems, meeting global environmental regulations (CE, EPA) for construction sites.

Application Scenarios of Stone Crusher Sand Making Machine

Building Construction: Produces high-grade sand for concrete, mortar, and brick manufacturing, supporting residential, commercial, and industrial building projects.

Road & Railway Construction: Supplies aggregates for road bases, subgrades, and railway ballast, ensuring pavement stability and durability.

Bridge & Hydraulic Engineering: Provides high-purity sand for bridge piers, dams, and water conservancy facilities, withstanding harsh environmental conditions.

Aggregate Production Plants: Serves as the core equipment for commercial aggregate plants, producing artificial sand for sale to construction companies.

Concrete Batching Plants: Integrates with concrete mixing systems to supply on-demand sand, improving concrete quality and production efficiency.

How to Choose the Right Stone Crusher Sand Making Machine?

Material Type & Hardness: Choose a model with robust crushing components for hard stones (basalt, granite) or a cost-effective design for soft stones (limestone).

Production Capacity: Match the machine’s output (50-500 TPH) to your project’s daily/weekly sand demand.

Finished Sand Specifications: Determine the required fineness modulus and particle size (0.15-5mm) to select the appropriate sand making and screening configuration.

Site & Space Constraints: Opt for mobile stone crusher sand making machine for flexible relocation; stationary models for fixed-site plants.

Environmental Requirements: Prioritize models with dust suppression and low-noise features for urban or eco-sensitive areas.