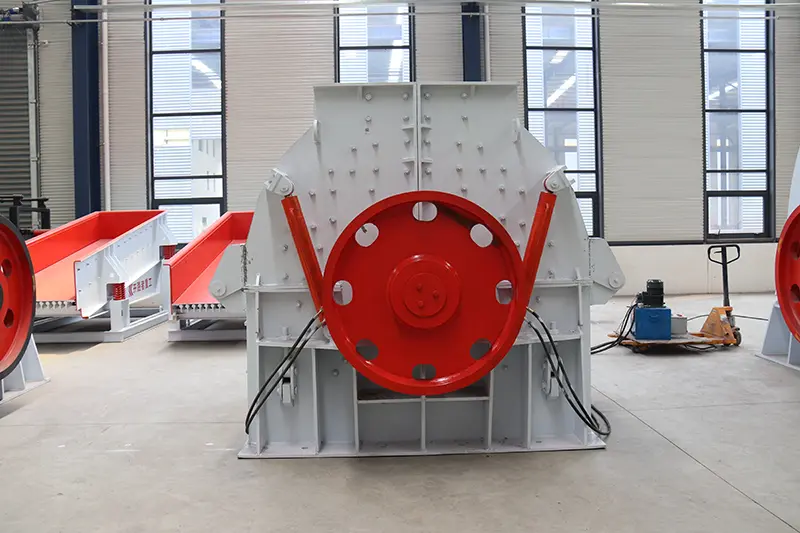

In the global construction and aggregate industry, the demand for high-quality artificial sand continues to rise, making a reliable sand making machine from stone an indispensable asset. Among the top-tier equipment in this field, the

PCK Series Sand Making Machine stands out as a specialized solution designed to transform hard stones (granite, limestone, river pebbles, basalt) into premium cubical sand. This sand making machine from stone combines advanced technology, robust design, and energy efficiency—catering to large-scale construction, quarrying, and infrastructure projects. Below is a comprehensive guide to the PCK Series Sand Making Machine, its working principle, core advantages, applications, and why it’s the preferred stone-to-sand equipment for industry professionals.

A sand making machine from stone is industrial equipment engineered to crush, shape, and grade natural stones or recycled concrete into high-quality artificial sand. Unlike natural sand, which is limited and environmentally sensitive, sand produced by a sand making machine from stone meets strict construction standards—with uniform particle size, cubical shape, and low impurity content. The PCK Series Sand Making Machine elevates this process with specialized design tweaks, making it ideal for handling hard, abrasive stones and delivering consistent output for concrete, asphalt, and building projects.

The PCK Series Sand Making Machine operates on the principle of “impact crushing + particle shaping,” ensuring efficient stone-to-sand conversion:

Material Feeding: Stones (5-30mm in size, crushed by jaw/cone crushers) are uniformly fed into the PCK Series Sand Making Machine via a vibrating feeder.

High-Speed Impact: The machine’s rotor rotates at 1200-1800 rpm, accelerating stones to high velocity. Materials collide with the rotor’s hammerheads, then impact the anvil liner and other particles (particle-on-particle crushing).

Particle Shaping: This dual impact process refines stones into cubical sand with low flakiness (≤8%), eliminating irregular shapes common in traditional crushing.

Screening & Recycling: Qualified sand (0-5mm, 5-10mm) is sorted by a built-in vibrating screen and discharged. Oversize particles are recycled back to the crushing chamber for reprocessing—ensuring zero waste.

This streamlined workflow makes the PCK Series Sand Making Machine a highly efficient sand making machine from stone, with a production capacity of 50-300 TPH to meet diverse project needs.

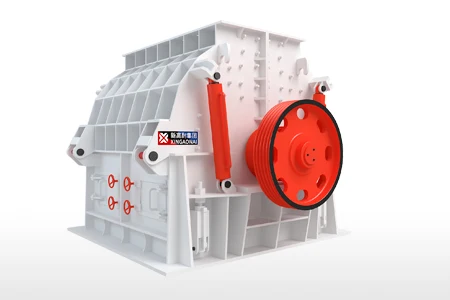

Dual-Crushing Structure: Combines impact crushing and particle-on-particle collision to enhance sand quality and production efficiency.

Wear-Resistant Components: Hammerheads and liners are made of high-chromium alloy steel, resisting abrasion from hard stones like granite—extending service life by 30% vs. ordinary models.

Energy-Saving Design: Equipped with IE3 high-efficiency motors and optimized rotor geometry, reducing energy consumption by 15-20% per ton of sand.

Easy Maintenance: Modular design allows quick replacement of wear parts; a side access door simplifies inspection and cleaning—minimizing downtime.

Wide Material Adaptability: Handles all hard stones (granite, limestone, basalt, river pebbles) and recycled concrete, making it a versatile sand making machine from stone.

As a professional sand making machine from stone, the PCK Series serves multiple high-demand sectors:

Construction Industry: Produces premium sand for high-strength concrete, mortar, and building foundations—meeting ASTM and ISO construction standards.

Quarrying & Aggregate Production: Processes crushed stone into graded sand for road construction, railway ballast, and municipal engineering projects.

Commercial Sand-Making Plants: Acts as the core equipment in stone-to-sand production lines, supplying sand to concrete batching plants and construction companies.

Infrastructure Projects: Used in dam construction, airport runways, and bridge projects where high-quality sand is critical for structural durability.

Construction Waste Recycling: Converts demolished concrete, brick, and asphalt into recycled sand—promoting environmental sustainability and resource reuse.

Why select the PCK Series over other sand making machine from stone options? Its unique benefits deliver long-term value:

Superior Sand Quality: Cubical particle shape (flakiness rate <8%) and uniform gradation improve concrete workability and strength.

Higher Efficiency: Dual-crushing design boosts production capacity by 20-30%—ideal for large-scale projects with tight deadlines.

Lower Operational Costs: Energy-saving motors and durable wear parts reduce electricity bills and maintenance expenses by 15-25%.

Easy Operation & Automation: Intelligent control reduces manual intervention; automatic overload protection prevents equipment damage.

Global Compliance: Meets CE, ISO, and SGS certifications, ensuring safety and performance for international markets.

When investing in a sand making machine from stone, consider these factors to match the PCK Series to your needs:

Raw Material Hardness: Select a model with appropriate rotor power (55-250kW) based on stone type (e.g., 160kW+ for granite/basalt).

Production Capacity: PCK Series offers 50-300 TPH models—choose based on daily output requirements (e.g., 100-150 TPH for medium-sized sand plants).

Sand Quality Requirements: Confirm the machine can produce target particle sizes (0-5mm, 5-10mm) and cubical shape for your application.

After-Sales Support: Partner with a supplier offering on-site installation, operator training, and 24/7 technical support—critical for minimizing downtime.

The

PCK Series Sand Making Machine redefines what a high-performance sand making machine from stone can deliver. Its advanced dual-crushing technology, energy efficiency, and superior sand quality make it the top choice for construction, quarrying, and recycling operations worldwide. Whether you’re converting granite into construction sand or recycling concrete into usable aggregates, the PCK Series ensures consistent output, lower costs, and competitive advantages in the global market.