The construction of gyratory crusher is a key engineering factor that determines crushing capacity, operational stability, maintenance efficiency, and service life. As a primary crushing machine widely used in mining and large-scale aggregate processing, a gyratory crusher is built with a heavy-duty structure designed to withstand continuous high-load operation.

1. Overall Structural Design of a Gyratory Crusher

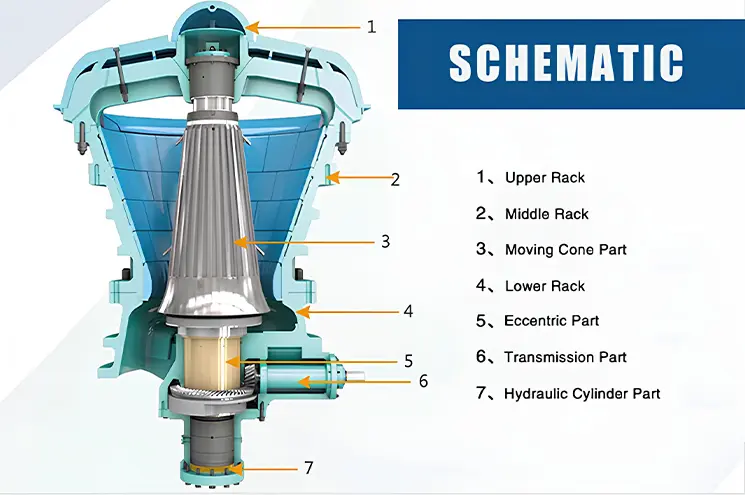

From a structural perspective, the construction of gyratory crusher follows a vertical layout. The machine is composed of an upper frame, middle crushing section, and lower drive and support system. This vertical arrangement allows gravity-assisted material flow, improving throughput and reducing energy consumption.

The rigid frame structure ensures excellent load-bearing capacity, making the crusher suitable for processing hard and abrasive ores.

2. Main Frame and Supporting Structure

The main frame is the foundation of the construction of gyratory crusher. It supports the crushing chamber and absorbs dynamic loads generated during operation. High-strength cast steel or welded steel structures are commonly used to ensure durability and resistance to deformation.

A well-designed supporting structure also reduces vibration transmission to the foundation, improving overall operational stability.

3. Crushing Chamber Components

The crushing chamber is the core working area in the construction of gyratory crusher. It consists of:

Mantle, mounted on the main shaft

Concave liners, fixed inside the upper frame

As the mantle performs a continuous gyratory motion, material is compressed between the mantle and concaves. The chamber profile is carefully engineered to ensure uniform wear, consistent product size, and high reduction ratios.

Different chamber designs can be selected according to feed size and capacity requirements.

4. Main Shaft and Eccentric Assembly

The main shaft is a central load-bearing component in the construction of gyratory crusher. It supports the mantle and transfers crushing forces to the eccentric assembly.

The eccentric mechanism generates the circular movement of the shaft, enabling continuous crushing. Precision machining and robust bearing arrangements are essential to ensure smooth rotation and long-term reliability.

5. Drive System and Power Transmission

The drive system is another critical part of the construction of gyratory crusher. It typically includes an electric motor, transmission shaft, and gear system. Power is transferred efficiently to the eccentric assembly to maintain stable crushing motion.

Proper alignment and enclosed gear structures help reduce mechanical losses and protect internal components from dust contamination.

6. Lubrication, Sealing, and Cooling Systems

Modern construction of gyratory crusher integrates advanced lubrication systems to supply oil to bearings, gears, and rotating parts. Automatic lubrication ensures consistent oil flow and prevents overheating.

Sealing systems are designed to keep dust and debris out of critical components, significantly extending equipment service life and reducing maintenance downtime.

7. Safety and Maintenance-Oriented Design

Safety is an important consideration in the construction of gyratory crusher. Hydraulic adjustment systems allow operators to control the discharge opening and compensate for liner wear. Overload protection mechanisms help prevent damage caused by uncrushable materials.

Additionally, the modular design of liners and internal components simplifies inspection and replacement, reducing maintenance time and operational costs.

8. Structural Advantages in Primary Crushing Applications

Thanks to its robust construction, a gyratory crusher offers:

High continuous crushing capacity

Stable and smooth operation

Lower operating and maintenance costs

Long service life under heavy-duty conditions

These advantages make the construction of gyratory crusher ideal for large mines and high-output aggregate plants.