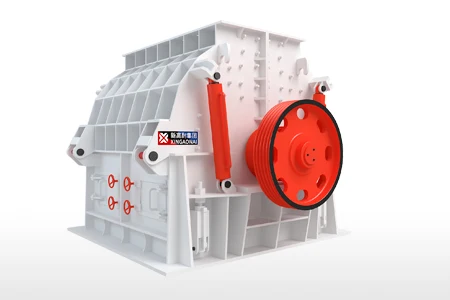

What Is a Double-Rotor Sand Making Machine?

How Does a Double-Rotor Sand Making Machine Work?

Material Feeding: Raw materials (5-30mm in size) are fed into the machine’s crushing chamber via a vibrating feeder.

Dual-Rotor Impact: Two rotors rotate at high speed (1200-1800 rpm) in opposite directions. Materials first collide with the first rotor’s hammerheads, then are immediately impacted by the second rotor—creating double crushing force.

Particle Shaping: After dual impact, materials collide with the chamber’s anvils and with each other (particle-on-particle crushing), refining into cubical sand with low flakiness (≤10%).

Screening & Recycling: Qualified sand (0-5mm) is discharged, while oversize particles are recycled back to the crushing chamber for reprocessing—ensuring no waste.

Core Advantages of the Double-Rotor Sand Making Machine for Sale

High Production Efficiency: Dual rotors deliver double impact force, increasing throughput by 20-30% compared to single-rotor models—ideal for large-scale sand production.

Superior Sand Quality: Cubical particle shape (flakiness rate <10%) and uniform gradation meet high-grade concrete and asphalt requirements.

Energy Saving: Optimized rotor design and transmission system reduce energy consumption by 15-25% per ton of sand, lowering operational costs.

Durable & Low Maintenance: Hammerheads and anvils are made of high-chromium alloy steel, resisting wear from hard materials like granite. The simple structure minimizes maintenance downtime.

Versatile Material Adaptability: Handles diverse raw materials—granite, limestone, river pebbles, basalt, and recycled concrete—expanding application scope.

Easy Operation: Equipped with PLC control systems for automated operation; operators can adjust rotor speed and discharge settings via a touchscreen.

Key Applications of the Double-Rotor Sand Making Machine for Sale

Construction Industry: Produces premium sand for concrete, mortar, and building foundations—meeting the demand for durable construction materials.

Quarrying & Aggregate Production: Processes crushed stone into graded sand for road construction, railway ballast, and municipal engineering.

Sand-Making Plants: Serves as the core equipment in commercial sand-making lines, supplying sand to construction companies and concrete batching plants.

Construction Waste Recycling: Converts demolished concrete, brick, and asphalt into recycled sand—promoting environmental sustainability and resource reuse.

Mining Industry: Processes ore tailings into usable sand, reducing waste and creating additional revenue streams for mines.

How to Choose the Right Double-Rotor Sand Making Machine for Sale?

Raw Material Properties: Choose a model with suitable rotor power and hammerhead material based on material hardness (e.g., high-chromium hammerheads for granite).

Production Capacity: Select a machine matching your daily output requirements (ranging from 50-500 TPH for double-rotor models).

Sand Quality Requirements: Ensure the machine can produce sand with the required particle size (0-5mm, 5-10mm) and cubical shape for your application.

Energy Efficiency: Prioritize models with IE3/IE4 motors and optimized rotor design to reduce long-term operational costs.

Manufacturer Reliability: Partner with a reputable supplier offering genuine parts, after-sales service, and technical support—critical for minimizing downtime.

Budget & ROI: Balance upfront costs with long-term savings (energy, maintenance) to maximize return on investment.

Why Invest in Our Double-Rotor Sand Making Machine for Sale?

Customizable Configurations: We offer models with 50-500 TPH capacity, tailored to your specific production needs.

Quality Assurance: All components undergo strict quality testing, with a 12-month warranty on key parts.

Energy-Saving Design: Reduces energy consumption by up to 25%, cutting operational costs significantly.

Professional Support: Our team provides on-site installation, operator training, and 24/7 technical support.

Global Compliance: Meets international standards (CE, ISO) for safety and performance, ensuring market access worldwide.