Why Choose Xingaonai as Your Apron Feeder Manufacturer?

1. Customized Apron Feeders for Diverse Industrial Needs

Material characteristics (abrasiveness, moisture content, particle size, weight)

Production capacity (5–1000 TPH)

Site constraints (space, layout, environmental conditions)

Downstream equipment compatibility (crushers, screens, grinders)

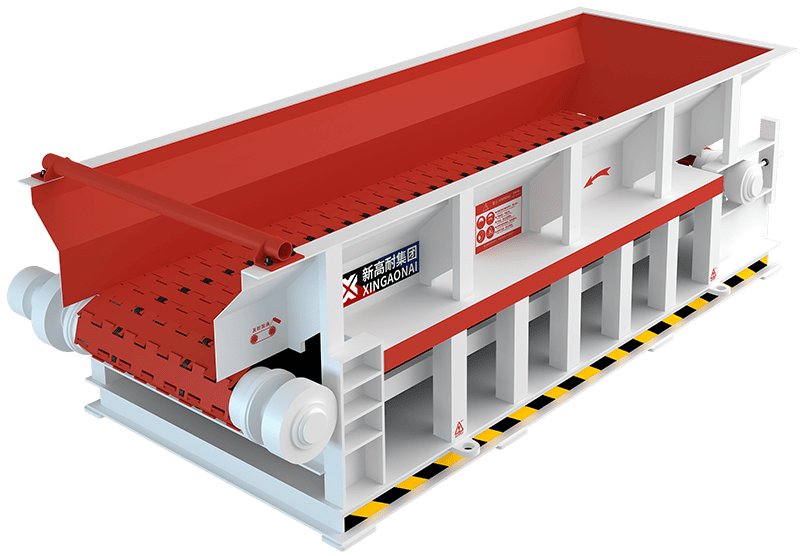

2. Robust & Wear-Resistant Construction

Pans/Plates: High-strength manganese steel or wear-resistant alloy plates (thickness 12–30mm) that resist impact and abrasion, extending service life by 30–40% compared to standard models.

Chain Drive System: Heavy-duty roller or pintle chains with heat-treated links, designed to handle extreme loads without deformation.

Frame: Reinforced welded steel frame with anti-vibration design, absorbing impact from falling materials and ensuring stable operation.

Components: Corrosion-resistant hardware and sealed bearings, suitable for outdoor, humid, or dusty environments (e.g., open-pit mines, coastal quarries).

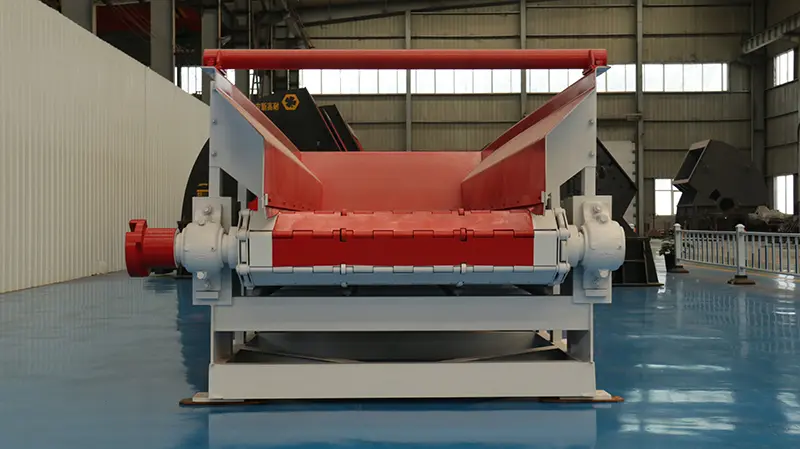

3. Advanced Technology & Energy Efficiency

Intelligent Control: PLC systems with variable frequency drives (VFDs) allow precise adjustment of feeding speed (0.05–0.5 m/s), matching downstream processing capacity and reducing energy consumption by 15–20%.

Condition Monitoring: Optional sensors for real-time tracking of chain tension, pan wear, and motor temperature, enabling predictive maintenance and minimizing downtime.

Eco-Friendly Design: Low-noise operation (≤85 dB) and sealed components to prevent material spillage, complying with global environmental and safety regulations.

4. Global Reach & Comprehensive After-Sales Support

On-Site Installation: Professional technicians oversee equipment setup and calibration to ensure optimal performance.

Operator Training: Hands-on training for staff on operation, safety protocols, and basic maintenance.

24/7 Technical Support: Responsive team available to address emergency issues or technical queries.

Genuine Spare Parts: Fast delivery of original components (pans, chains, bearings) to minimize downtime.

Long-Term Maintenance Contracts: Customized service packages for ongoing equipment upkeep.

5. Proven Track Record in Key Industries

A large iron ore mine in Australia selected Xingaonai as its apron feeder manufacturer, deploying 3 heavy-duty models that handle 800 TPH of ore boulders (up to 1.2m in diameter) with zero unplanned downtime for 2 years.

A quarry in Germany partnered with Xingaonai for custom chain apron feeders, designed to handle wet, sticky gravel without clogging—improving feeding efficiency by 25%.

A construction waste recycling plant in China chose Xingaonai’s compact apron feeders, fitting into limited site space while delivering 150 TPH of crushed concrete to recycling crushers.

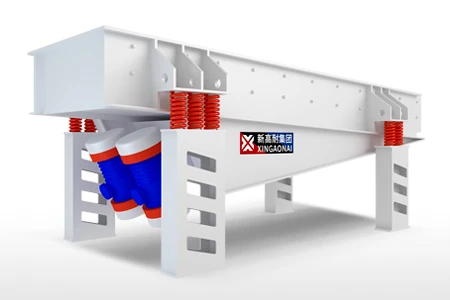

Xingaonai’s Apron Feeder Product Range

Heavy-Duty Apron Feeder: For mining, quarries, and large-scale aggregate production—handles materials weighing up to 5 tons per piece.

Chain Apron Feeder: Ideal for wet, sticky, or fine materials (e.g., coal, clay) with deep pans to prevent spillage.

Light-Duty Apron Feeder: Cost-effective solutions for construction, cement plants, and small quarries—handling sand, limestone fines, and lightweight aggregates.

Mobile Apron Feeder: Mounted on a mobile chassis for temporary projects (e.g., road construction, temporary mining sites)—offering flexibility in placement.

How to Partner with Xingaonai – Your Trusted Apron Feeder Manufacturer

Needs Assessment: Contact Xingaonai’s sales team to discuss your material type, production capacity, site conditions, and budget.

Custom Design: Engineers create a tailored solution with 3D models and technical drawings for your approval.

Manufacturing & Quality Control: Production follows strict ISO standards, with multiple inspections to ensure compliance.

Delivery & Installation: Global logistics support delivers equipment on time, with on-site setup and calibration.

Training & After-Sales: Operator training and ongoing technical support ensure long-term performance.