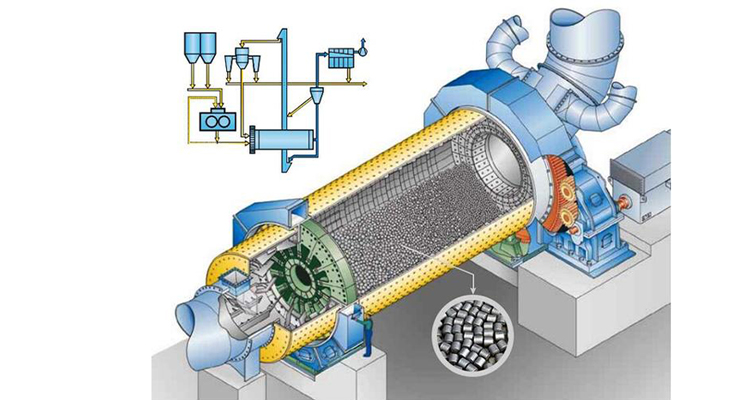

Sand Making Rod Mill

CAPACITY

FEED SIZE

CAPACITY

FEED SIZE

Sand making rod mill, also referred to as rod mill, is one of the widely used sand and gravel equipment in the sand and gravel industry. It is mainly suitable for making abrasives, refractory materials, cement, quartz sand, steel sand, iron ore, slag powder, For the fine and medium crushing of various hard and brittle materials such as gold ore, concrete aggregate, asphalt aggregate, etc., the rod mill can save energy by 50% compared with the traditional sand making machine. It is currently the most advanced sand making equipment in the world.

Save energy

40% less power than traditional models, and improved operating efficiency

Automation

Low energy consumption in production reduces cost input in production.

Adjustable output fineness

The discharge granularity can be changed, the built-in fineness control device, and the discharge can be equipped with a screening device.

Wide range of applications

It adopts advanced controllable feeding and discharging materials, which is suitable for ores with different hardness.

| Model | size (mm) | Feed size (mm) | Discharge size (mm) | Motor power (kw) | Capacity (tph) |

|---|---|---|---|---|---|

| BMJ-2136 | 2100*3600 | ≤30 | <5 | 280 | 80-100 |

| BMJ-2445 | 2400*4500 | ≤30 | <5 | 380 | 150-200 |

| BMJ-2745 | 2700*4500 | ≤30 | <5 | 450 | 200-300 |

| BMJ-2755 | 2700*5500 | ≤30 | <5 | 500 | 300-350 |

| BMJ-3255 | 3200*5500 | ≤30 | <5 | 800 | 400-450 |

| BMJ-3655 | 3600*5500 | ≤30 | <5 | 1250 | 450-500 |