High-Efficiency Agitation Tank

CAPACITY

FEED SIZE

CAPACITY

FEED SIZE

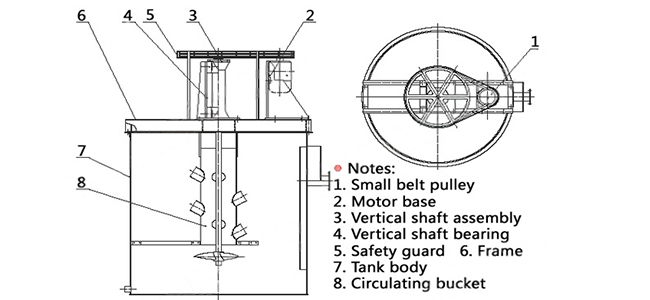

The High-Efficiency Agitation Tank is designed for optimal mixing performance in a wide range of industrial applications. It ensures thorough blending of slurries and liquid-solid mixtures, enhancing reaction efficiency and process consistency. Commonly used in mineral processing for pre-flotation agitation, it is also well-suited for chemical, metallurgical, building materials, cyanide processing, and wastewater treatment industries. With robust construction and efficient mixing capability, this tank delivers reliable operation and improved productivity in demanding environments.

Powerful Mixing Performance

With a large impeller diameter and high rotational speed, the tank offers strong mixing capability for both slurry and reagents.

Enhanced Circulation Efficiency

The enhanced mixing power also improves the circulation of slurry and reagents within the tank.

Optimized Suction and Flow Design

A flow guide installed inside the tank reduces excessive negative pressure within the limited space, thereby accelerating suction capacity and further strengthening reagent-slurry circulation, while also enhancing both suction and circulation performance.

Jet-Assisted Circulation Boost

A jet device is installed at the bottom of the flow guide, which further boosts the circulation of reagents and slurry, contributing to improved flotation performance.

| Model | Effective Volume (m³) | Rotating Speed of Impeller (r/min) | Diameter of Impeller (mm) | Motor Model | Motor power (kw) | Weight (kg) |

|---|---|---|---|---|---|---|

| GBJ-1000X1000 | 0.58 | 530 | 240 | Y112M-6 | 2.2 | 548 |

| GBJ-1250X1250 | 1.15 | 350 | 240 | Y100L2-4 | 3 | 820 |

| GBJ-1500X1500 | 2.2 | 320 | 420 | Y132M2-6 | 5.5 | 1350 |

| GBJ-2000X2000 | 5.46 | 240 | 560 | Y160M-6 | 7.5 | 3173 |

| GBJ-2500X2500 | 11.2 | 232 | 560 | Y180L-6 | 15 | 3939 |

| GBJ-3000X3000 | 19.1 | 220 | 700 | Y225S-8 | 18.5 | 6676 |

| GBJ-3500X3500 | 31 | 248 | 700 | Y225M-8 | 22 | 7581 |

| GBJ-4000X4000 | 45 | 153 | 1000 | Y250M-8 | 37 | 9560 |