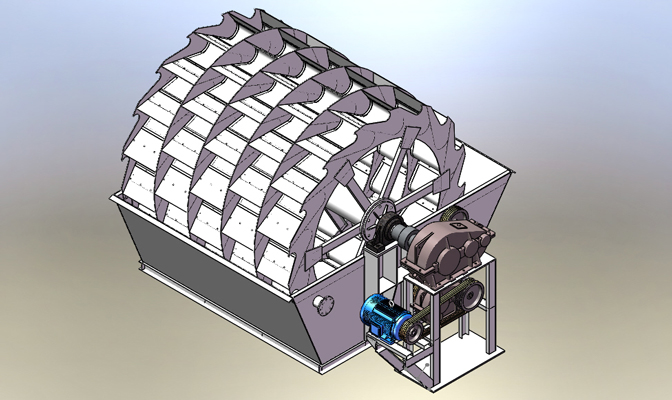

XS Series Wheel Bucket Sand Washing Machine

CAPACITY

FEED SIZE

CAPACITY

FEED SIZE

The wheel bucket sand washing machine has the characteristics of high cleanliness of finished products, large processing capacity, low power consumption and long service life. It plays an indispensable role in the artificial sand wet processing process and is widely used in sand and gravel yards. , mining, building materials, water conservancy and hydropower, and concrete mixing stations can effectively improve the cleanliness and quality of finished sand, and are the preferred equipment for upgrading the sand washing industry today.

Durable and stable

The impeller drive bearing device is isolated from water and water-receiving materials, which effectively reduces the failure rate and saves costs; it operates normally in harsh environments.

High degree of cleaning

The fineness modulus meets the standard requirements, meets the requirements of high-grade materials, and is widely used.

Less material loss

During the sand washing process, the loss of fine sand and stone powder is small, and it has a new sealing structure and an adjustable overflow weir plate.

Less wearing parts

No wearing parts, less maintenance, long service life; water washing process avoids dust pollution, mud and water are separated, and water resources are reused.

| Model | Impeller (outside diameter*width) (mm) | Impeller speed (r/min) | Max Feed Size (mm) | Capacity (tph) | Motor power (kw) | Dimensions (mm) |

|---|---|---|---|---|---|---|

| XGN-XS2610 | 2600*1000 | 1.178 | ≤10 | 20-50 | 5.5 | 3255*1982*2690 |

| XGN-XS2816 | 2800*1600 | 1.177 | ≤10 | 30-60 | 11 | 3540*3000*2880 |

| XGN-XS3016 | 3000*1600 | 1.179 | ≤10 | 50-120 | 15 | 3845*3000*3080 |

| XGN-XS3220 | 3200*2000 | 1.18 | ≤10 | 70-160 | 15 | 4100*3560*3300 |

| XGN-XS3230 | 3200*3000 | 1.18 | ≤10 | 180-220 | 18.5 | 4100*3560*3300 |

| XGN-XS3620 | 3600*2000 | 1.18 | ≤10 | 100-180 | 18.5 | 4600*3560*3700 |