YDG Series Roller Sand Making Machine

CAPACITY

FEED SIZE

CAPACITY

FEED SIZE

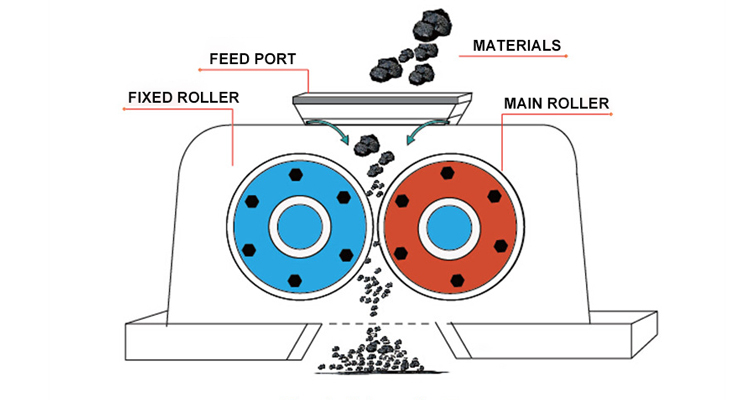

The double-roller sand making machine uses the principle of double-roller extrusion and lamination extrusion to realize material extrusion and molding efficiently and quickly. It is a world-recognized production capacity and low-energy briquette granulation equipment, and is widely used in the fields of coal energy, energy conservation and environmental protection.

Easy to adjust

It can be adjusted by adjusting the wedge block or spacer between the two rollers to obtain the ideal particle size of the finished product.

Wide application range

It can be used for mineral processing, chemical industry, cement, refractory materials, abrasive materials, building materials and other industrial sectors, and various high and medium hardness ores and rocks, especially in the production of melon stones and other products in the building materials industry.

Accessories use high-quality materials

The whole machine is made of high-quality wear-resistant materials, especially the grinding roller, which can be used repeatedly and has low failure rate, which can bring long-term benefits to customers.

Low production cost

Made of advanced materials, the parts wear less, reduce the number of replacement parts, and reduce production costs.

| Model | Roller diameter (mm) | Roller surface width (mm) | Feed size (mm) | Motor power (kw) | Capacity (tph) |

|---|---|---|---|---|---|

| YDG-1080 | 1000 | 800 | ≤30 | 2*37 | 50-80 |

| YDG-1210 | 1200 | 1000 | ≤30 | 2*75 | 100-120 |

| YDG-1212 | 1200 | 1200 | ≤30 | 2*90 | 120-150 |

| YDG-1510 | 1500 | 1000 | ≤30 | 2*132 | 140-170 |

| YDG-1810 | 1800 | 1000 | ≤40 | 2*220 | 160-230 |

| YDG-2012 | 2000 | 1200 | ≤40 | 2*315 | 250-300 |