Double Roll Crusher

CAPACITY

FEED SIZE

CAPACITY

FEED SIZE

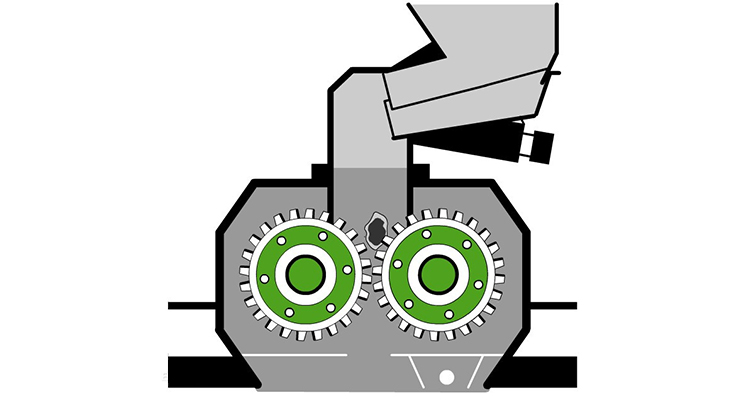

The Double Roll Crusher is also called the grading toothed stick crusher. It is a new concept of grading crushing equipment developed by our Xingaonai Group based on years of industry experience and advanced technology. Its innovative tooth rolling technology can ensure the quality of materials. High-efficiency crushing operation, with obvious advantages in handling dry materials, wet materials, mud materials and sticky materials without clogging.

High broken rate

The crushing teeth are cast with Babbitt grinding alloy, and the service life is 2-3 times that of high-strength steel and alloy steel commonly used in the industry; the dual-structure independent drive device is energy-saving and efficient.

Excellent shape

The shape of the stick surface is divided into coarse and fine tooth rollers, which can be adjusted according to the size of the material required for production; low speed, special tooth shape, less over-grinding and over-graining of materials, and the proportion of finished products in the 40-90mm section can reach 75%.

Cost-effective

The crushing tooth type, crushing tooth arrangement and walking structure are diversified, which can be optimized and selected for customers according to the working conditions, customized, high crushing efficiency, and easy maintenance.

Reasonable design

Special main shaft structure, crushing rod cleaning device, intelligent control system, easy to operate; the crushing chamber adopts the overall box structure, and the working environment is clean.

| Model | Rotor diameter (mm) | Roller surface width (mm) | Feed size (mm) | Output size (mm) | Motor power (kw) | Capacity (tph) |

|---|---|---|---|---|---|---|

| 2PGC90200 | 900 | 2000 | ≤300 | ≤90 | 2*90 | 300 |

| 2PGC100250 | 1000 | 2500 | ≤350 | ≤90 | 2*160 | 600 |

| 2PGC120300 | 1200 | 3000 | ≤400 | ≤90 | 2*220 | 1000 |