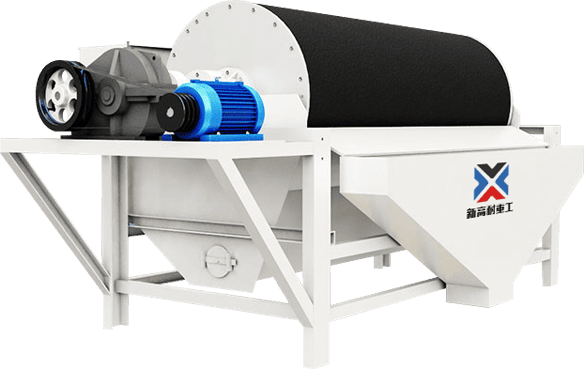

Working Principle of Wet Permanent Magnetic Drum Separator

Slurry Feeding: Mineral slurry (a mixture of water and crushed ore particles) is uniformly fed into the separation zone of the magnetic drum via a feeding device. The slurry concentration is typically controlled at 20-40% to ensure optimal magnetic adsorption.

Magnetic Adsorption: The core component of the wet permanent magnetic drum separator is a rotating drum with an internal fixed permanent magnet system (usually made of neodymium-iron-boron or ferrite magnets). As the drum rotates, the permanent magnets generate a strong magnetic field (1000-6000 Gauss, depending on the model) in the working zone.

Material Separation: Magnetic mineral particles in the slurry are attracted to the drum surface by the magnetic force, while non-magnetic particles remain in the slurry. As the drum continues to rotate, the magnetic particles are carried away from the magnetic zone.

Discharge of Products: Once the magnetic particles move to the non-magnetic zone of the drum, they lose magnetic attraction and fall into the magnetic product hopper. The non-magnetic slurry flows out through the discharge port into the non-magnetic product collection system, completing the separation process.

Core Advantages of Wet Permanent Magnetic Drum Separator

High Separation Efficiency & Mineral Recovery: The strong and uniform magnetic field of the wet permanent magnetic drum separator ensures effective adsorption of magnetic minerals, even fine-grained particles (down to 0.074mm). This results in high recovery rates (often above 95% for magnetic minerals like magnetite), minimizing valuable mineral loss.

Energy-Saving & Low Operational Costs: Equipped with permanent magnets, the separator does not require external power to generate a magnetic field—only the drum rotation consumes minimal energy. This reduces energy costs significantly compared to electromagnetic separators. Additionally, permanent magnets have a long service life (5-10 years) with no demagnetization risk under normal operation.

Adaptability to Fine-Grained & Sticky Materials: The wet working mode prevents material blockage, making the separator ideal for processing fine-grained, slimy, or wet ores. Slurry flow washes away impurities, ensuring the magnetic drum maintains stable adsorption performance, even for materials with high moisture content.

Stable & Reliable Performance: The wet permanent magnetic drum separator features a robust structure—with a stainless steel drum shell, corrosion-resistant magnetic system, and heavy-duty bearing design. It can operate continuously under harsh industrial conditions (e.g., high humidity, dusty environments) with minimal downtime.

Simple Operation & Low Maintenance: The equipment has a simple structure with few moving parts. Operation only requires adjusting the slurry feeding rate and drum rotation speed. Routine maintenance mainly involves cleaning the drum surface and checking bearings, saving time and labor costs.

Environmentally Friendly: The wet separation process produces no dust pollution, meeting environmental protection standards. It also requires no chemical reagents, avoiding secondary pollution to the environment or mineral products.

Common Types of Wet Permanent Magnetic Drum Separator

Low-Intensity Wet Permanent Magnetic Drum Separator (1000-3000 Gauss): Suitable for separating strongly magnetic minerals such as magnetite, maghemite, and iron filings. It is widely used in iron ore beneficiation, steel plant waste recycling, and coal washing industries.

Medium-Intensity Wet Permanent Magnetic Drum Separator (3000-5000 Gauss): Designed for separating weakly magnetic minerals like hematite, limonite, and manganese ore after magnetization roasting. It is commonly used in non-ferrous metal mining and metallurgical processing.

High-Intensity Wet Permanent Magnetic Drum Separator (5000-8000 Gauss): Ideal for separating weakly magnetic and fine-grained minerals such as ilmenite, rutile, and tantalum-niobium ore. It is widely applied in rare earth mineral processing and electronic waste recycling.

Single-Drum Wet Permanent Magnetic Separator: The most common type, featuring a single rotating drum. It is suitable for small to medium-scale production lines and simple separation requirements.

Double-Drum Wet Permanent Magnetic Separator: Equipped with two parallel magnetic drums for two-stage separation. It achieves higher sorting precision and is ideal for high-quality mineral concentrate production in large-scale mineral processing plants.

Applications of Wet Permanent Magnetic Drum Separator

Mining Industry: The primary application field—used in iron ore, manganese ore, titanium ore, and rare earth ore beneficiation to separate magnetic minerals from gangue. For example, in magnetite processing, it upgrades low-grade ore into high-quality concentrate (Fe content ≥65%).

Metallurgical Industry: Used in steelmaking, non-ferrous metal smelting, and alloy production to remove magnetic impurities from raw materials, ensuring product purity. It also recycles magnetic waste (e.g., iron scrap, steel slag) for resource reuse.

Building Materials Industry: Applied in cement production to remove iron impurities from limestone, clay, and other raw materials, protecting downstream equipment (e.g., crushers, grinders) from wear. It is also used in glass manufacturing to purify quartz sand.

Recycling Industry: Used to recover magnetic materials from industrial waste, such as iron filings from machining waste, magnetic metals from electronic waste, and steel fibers from concrete waste. This supports circular economy development.

Coal Washing Industry: Separates iron pyrite and magnetic minerals from coal, reducing ash content and improving coal quality for power generation and industrial use.

Key Factors to Consider When Selecting a Wet Permanent Magnetic Drum Separator

Mineral Magnetic Susceptibility: Select the magnetic field intensity based on the mineral’s magnetic properties. Strongly magnetic minerals require low-intensity separators, while weakly magnetic minerals need medium or high-intensity models.

Particle Size & Slurry Concentration: For fine-grained minerals (≤0.1mm), choose a high-intensity separator with a slow drum rotation speed. Adjust the separator type based on slurry concentration—higher concentration requires a larger drum diameter for effective separation.

Production Capacity: Determine the required processing capacity (t/h) based on your production line output. Select a separator model with a capacity that matches your needs—small models (10-50 t/h) for small mines, large models (100-500 t/h) for large-scale processing plants.

Magnet Material: Choose between ferrite and neodymium-iron-boron (NdFeB) magnets. Ferrite magnets are cost-effective for low-intensity applications, while NdFeB magnets offer higher magnetic strength and longer service life for medium-high intensity needs.

Drum Material & Speed: The drum shell should be made of wear-resistant stainless steel to withstand slurry erosion. Adjust the drum speed based on separation requirements—higher speed for coarse particles, lower speed for fine particles to ensure sufficient magnetic adsorption time.