An Overview of Multi-Cylinder Hydraulic Cone Crusher Specification

Key Categories of Multi-Cylinder Hydraulic Cone Crusher Specification

1. Basic Structural Specifications

Overall Dimensions (Length × Width × Height): This specification indicates the equipment’s volume, which is a key factor in determining whether it can fit into the existing production site. For example, a typical medium-sized multi-cylinder hydraulic cone crusher may have overall dimensions of 3800×2800×3600mm. Users need to confirm the installation space, transportation routes, and hoisting conditions based on this specification.

Weight: The weight of the equipment (usually in tons) is related to its structural stability and transportation cost. Heavy-duty models (15-50 tons) are more stable during high-intensity operation but require more robust hoisting equipment and transportation vehicles. Lightweight models (5-15 tons) are suitable for small-scale production sites with limited hoisting capacity.

Crushing Cavity Type: A critical structural specification that determines the crushing principle and product granularity. Common cavity types include standard cavity, medium cavity, and short-head cavity. Standard cavity is suitable for coarse crushing, medium cavity for medium crushing, and short-head cavity for fine crushing. This specification is often matched with the equipment’s model to meet different crushing stage requirements.

2. Core Performance Specifications

Processing Capacity: One of the core specifications, referring to the amount of material processed per hour (unit: t/h). The processing capacity of multi-cylinder hydraulic cone crushers ranges from 50t/h to 1500t/h, depending on the model. For example, small models (e.g., HST100) have a capacity of 50-150t/h, while large models (e.g., HST500) can reach 800-1500t/h. This specification must match the user’s daily production output requirements.

Feed Size: Indicates the maximum particle size of raw materials that the equipment can handle (unit: mm). Common feed sizes range from 100mm to 500mm. For example, if the feed size specification is ≤300mm, raw materials larger than 300mm need to be pre-crushed to avoid damaging the equipment or affecting crushing efficiency.

Discharge Size Range: Determines the granularity of the final product, usually adjustable within a certain range (unit: mm). For example, the discharge size can be adjusted from 5mm to 60mm by changing the eccentric distance or adjusting the hydraulic system. This specification must align with the user’s requirements for final product granularity (e.g., aggregate for concrete requires 5-20mm discharge size).

Motor Power: Refers to the power of the drive motor (unit: kW), which provides the energy for crushing. Motor power ranges from 55kW to 630kW, with larger power corresponding to higher processing capacity and stronger crushing capacity for hard materials. For example, crushing granite (compressive strength ≥300MPa) requires a motor power of at least 200kW to ensure efficient crushing.

Eccentric Distance: Affects the crushing force and product granularity. Larger eccentric distance increases crushing force, suitable for coarse crushing; smaller eccentric distance ensures finer product granularity, suitable for fine crushing. This specification is usually adjustable or matched with different cavity types.

3. Applicable Material Specifications

Maximum Compressive Strength of Materials: Indicates the maximum hardness of materials that the equipment can handle (unit: MPa). Multi-cylinder hydraulic cone crushers are suitable for materials with compressive strength ≤350MPa, such as granite, basalt, diabase, limestone, and iron ore. If the material’s compressive strength exceeds this specification, the equipment may experience excessive wear or reduced service life.

Material Moisture Content: Most multi-cylinder hydraulic cone crushers require the material moisture content to be ≤8%. If the moisture content is too high (exceeding the specification), the material may adhere to the crushing cavity, causing blockages and reducing processing efficiency.

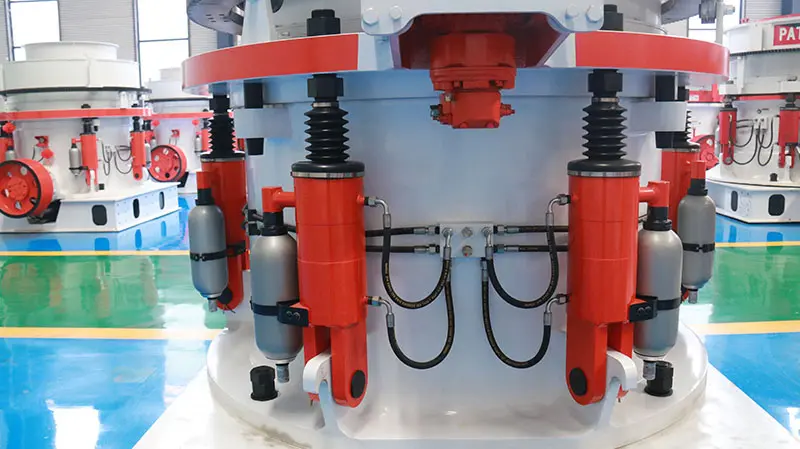

4. Hydraulic System Specifications

Hydraulic System Pressure: Usually ranging from 16MPa to 25MPa, this specification determines the equipment’s ability to adjust the discharge gap and protect against overload. When the equipment encounters uncrushable materials (e.g., metal blocks), the hydraulic system automatically relieves pressure to avoid damage to the main components.

Oil Tank Capacity: Refers to the volume of the hydraulic oil tank (unit: L), which affects the heat dissipation and stability of the hydraulic system. Larger oil tank capacity is beneficial for heat dissipation, suitable for long-term continuous operation.

How to Read & Use Multi-Cylinder Hydraulic Cone Crusher Specification

Match Capacity with Production Requirements: Calculate the required hourly processing capacity based on the daily production output, and select a model whose capacity specification is 10-20% higher than the actual demand to avoid production bottlenecks.

Align Feed & Discharge Sizes with Material & Product Needs: Confirm the maximum particle size of raw materials and select a feed size specification that matches. At the same time, ensure the discharge size range covers the required final product granularity.

Select Motor Power Based on Material Hardness: For hard materials (e.g., basalt), choose a model with higher motor power; for soft materials (e.g., limestone), a medium-power model is sufficient to save energy costs.

Consider Installation Space & Transportation Conditions: Based on the overall dimensions and weight specifications, confirm whether the production site has sufficient installation space and whether the transportation route and hoisting equipment can meet the requirements.

Refer to Hydraulic System Specifications for Safety & Stability: Prioritize models with stable hydraulic system pressure and sufficient oil tank capacity to ensure safe operation and reduce downtime due to hydraulic system failures.

Common Misunderstandings About Multi-Cylinder Hydraulic Cone Crusher Specification

Blindly Pursuing Large Capacity: Choosing a model with excessively high capacity specification will increase initial investment and energy consumption, and may lead to low equipment utilization rate if the actual material supply is insufficient.

Ignoring Feed Size Limitations: Using raw materials larger than the specified feed size will cause excessive wear of the crushing cavity and hammerhead, and even block the equipment, affecting production efficiency.

Neglecting Cavity Type Matching: The cavity type specification directly affects the crushing effect. Choosing the wrong cavity type (e.g., using a short-head cavity for coarse crushing) will reduce processing capacity and product quality.