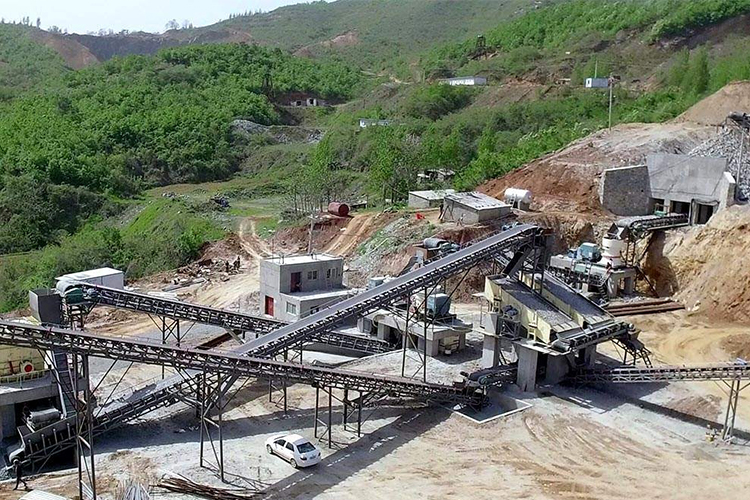

The stone crushing line is a comprehensive industrial system designed to transform raw rocks (granite, basalt, limestone, etc.) into high-quality aggregates for construction, infrastructure, and concrete production. From raw material preparation to final delivery, each stage of the stone crushing line is optimized for efficiency, quality, and adaptability to different hard rock types.

1. Raw Material Acquisition and Preparation

The stone crushing line starts with acquiring raw materials from quarries or mines via drilling, blasting, or excavating. Common materials include granite, basalt, and limestone—all inspected for size, hardness, and composition to ensure suitability for processing. Key equipment here includes excavators, wheel loaders, and dump trucks, which transport large rocks to the crushing line’s initial stage.

2. Primary Crushing

Primary crushing is the first core step of the stone crushing line. Raw rocks are fed into a primary crusher (typically a PE/PEV series jaw crusher for medium-hard to hard rocks, or a gyratory crusher for large-scale mining) to reduce them to 150–300mm— a manageable size for subsequent processing. This stage protects downstream equipment and lays the foundation for uniform aggregate quality.

3. Secondary Crushing

After primary crushing, the stone crushing line proceeds to secondary crushing to refine particle size. Materials are fed into cone crushers (GP/CS/HP series for hard/abrasive stones) or impact crushers (PF series for softer rocks like limestone), reducing them to 10–50mm—meeting basic shape and size requirements for construction aggregates.

4. Screening and Sizing

Screening is a critical quality control step in the stone crushing line. Processed materials pass through circular vibrating screens (YK series for general use) or linear vibrating screens (for fine separation) to separate into graded sizes. Unwanted fines or oversize materials are removed, ensuring the final product meets specific application standards.

5. Tertiary Crushing (Optional)

For finer aggregates (0–5mm) or specialized products, the stone crushing line adds a tertiary crushing stage. Common equipment includes VSI crushers (sand makers for artificial sand) or fine cone crushers, which further reduce particle size and refine shape—ideal for high-grade concrete or precision aggregates.

6. Washing and Scrubbing (Optional)

To produce clean aggregates, the stone crushing line may include a washing stage. Wheel sand washers (simple and efficient) or spiral sand washers (for thorough cleaning) remove impurities and contaminants, enhancing the aggregate’s purity for critical applications like high-strength concrete.

7. Stockpiling and Storage

Processed aggregates from the stone crushing line are stockpiled in designated plant areas via belt conveyors, wheel loaders, and dump trucks. This step ensures efficient material handling, prevents bottlenecks, and facilitates organized loading for distribution.

8. Loading and Distribution

Finished aggregates are loaded onto transport vehicles (trucks, conveyor belts, etc.) for safe delivery. The stone crushing line’s loading process is optimized to match distribution rhythms, ensuring timely supply to customers or storage facilities.

9. Customer Delivery and Utilization

The final stage of the stone crushing line involves delivering aggregates to construction sites, concrete plants, and infrastructure projects. These high-quality crushed stones are used for road construction, building foundations, landscaping, and concrete production—supporting diverse industrial and civil engineering needs.

Key Success Factors for the Stone Crushing Line

A reliable stone crushing line relies on proper planning, efficient process management, and strict quality control. Adherence to safety and environmental regulations, paired with adaptable equipment (for different rock types), ensures consistent production of high-quality aggregates. Each stage works in tandem to minimize waste, maximize efficiency, and meet the demands of modern construction and infrastructure projects.

Whether for small-scale construction or large-scale mining operations, the stone crushing line offers a flexible, full-process solution for turning raw rocks into essential building materials. Invest in a well-configured stone crushing line to achieve stable output, premium aggregate quality, and long-term operational value.