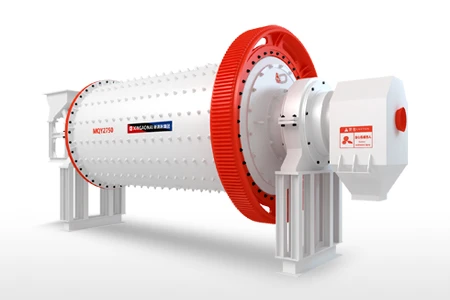

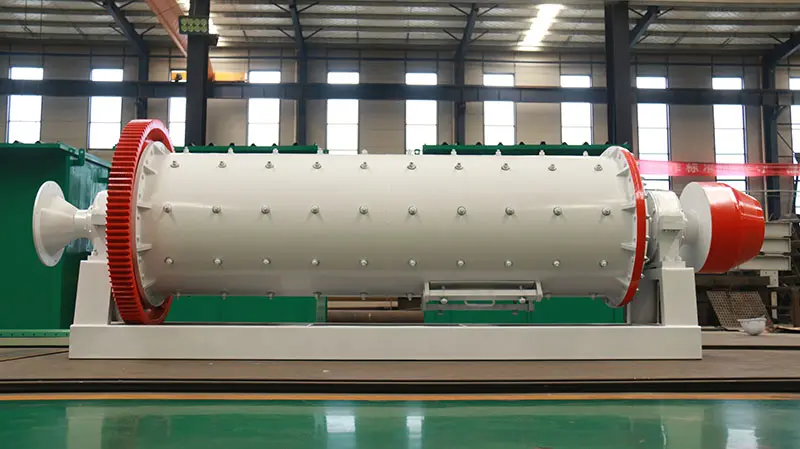

Working Principle of Mining Ball Mill

Feeding Stage: Crushed ore (with a particle size of 20-30mm) is fed into the mill cylinder through a feeding device, such as a hollow shaft or a feeding hopper. The feeding rate is carefully controlled to ensure optimal grinding efficiency and prevent overloading the mill.

Grinding Stage: When the mill cylinder rotates (driven by a motor and reducer), the steel balls inside the cylinder are lifted by the centrifugal force and the liner plate’s lifting ribs. As the cylinder continues to rotate, the steel balls fall freely or roll down, exerting strong impact force on the ore particles. Simultaneously, the friction between the steel balls and the ore, as well as between the ore particles themselves, achieves fine grinding.

Discharging Stage: The ground ore slurry (a mixture of fine ore particles and water) is discharged from the mill through a discharging device. For grid-type ball mills, the slurry passes through a grid plate that retains oversized particles for further grinding; for overflow-type ball mills, the slurry overflows from the hollow shaft when it reaches a certain level, ensuring the product meets the required particle size.

Core Types of Mining Ball Mill

Overflow-Type Mining Ball Mill: This type features a simple structure and smooth operation. The ore slurry overflows naturally from the discharge end, making it suitable for grinding ore into fine particles (0.074-0.4mm). It is widely used in gold, silver, and copper ore processing plants where fine grinding is required. The overflow-type design eliminates the need for a grid plate, reducing wear and maintenance costs.

Grid-Type Mining Ball Mill: Equipped with a grid plate at the discharge end, this type is designed for coarse to medium grinding (0.2-0.8mm). The grid plate controls the discharge particle size, ensuring that only particles meeting the requirement are discharged, while oversized particles are retained for regrinding. It is commonly used in iron ore, lead-zinc ore, and coal mining operations, as well as in the first stage of multi-stage grinding processes.

Wet-Type Mining Ball Mill: The most widely used type in mineral processing, the wet-type mining ball mill grinds ore with water, forming a slurry that is easy to transport and separate. It offers high grinding efficiency and uniform product granularity, making it ideal for most metal and non-metal ore processing. Wet-type ball mills are particularly suitable for ores that are difficult to grind dry, such as clay-rich or sticky ores.

Dry-Type Mining Ball Mill: This type grinds ore without water, producing dry powder products. It is mainly used in industries where water is scarce or where dry powder is required directly, such as cement production, coal beneficiation, and some non-metallic mineral processing. Dry-type ball mills are equipped with a dust collection system to prevent dust pollution.

Key Advantages of Mining Ball Mill

High Grinding Efficiency: The combination of impact and friction force generated by the rotating steel balls ensures efficient grinding of various ore types. Modern mining ball mills are equipped with advanced liner plates (e.g., high-chromium alloy liner plates) that enhance grinding efficiency and reduce energy consumption.

Wide Adaptability: Mining ball mills can handle a wide range of ore types, including hard ores (granite, basalt), brittle ores (limestone, coal), and metal ores (gold, copper, iron). They can also adjust the grinding fineness by changing the steel ball size, rotating speed, or feeding rate to meet different processing requirements.

Robust & Durable Construction: Designed for continuous heavy-duty use, mining ball mills feature a thick-walled cylinder made of high-quality steel, wear-resistant liner plates, and a reliable transmission system. With proper maintenance, a high-quality mining ball mill can operate stably for 10-15 years, providing long-term value for mining projects.

Easy Operation & Maintenance: The simple structure of mining ball mills makes them easy to operate and maintain. Routine maintenance mainly includes replacing liner plates and steel balls, which can be completed quickly with minimal downtime. Advanced models are also equipped with monitoring systems that allow real-time tracking of operating parameters, simplifying maintenance management.

Scalable Capacity: Mining ball mills are available in a wide range of capacities, from small-scale models (1-5 T/h) suitable for small mines to large-scale models (over 100 T/h) for large mineral processing plants. This scalability allows mining enterprises to select the appropriate model based on their production volume.

Applications of Mining Ball Mill in Mineral Processing

Metal Ore Processing: Used in gold, copper, iron, lead, zinc, and nickel ore processing to grind crushed ore into fine particles, facilitating the separation of valuable metals from gangue. For example, in gold mining, the mining ball mill grinds gold-bearing ore into slurry, which is then processed through flotation or cyanidation to extract gold.

Non-Metal Ore Processing: Applied in the processing of non-metallic minerals such as limestone, gypsum, quartz, and barite. The mining ball mill grinds these minerals into fine powder for use in cement, glass, ceramics, and chemical industries.

Coal Beneficiation: Used in coal mines to grind coal into fine powder for power generation or coal chemical production. Dry-type mining ball mills are commonly used in coal beneficiation to avoid moisture affecting coal quality.

Construction Material Production: Utilized in cement plants to grind clinker and gypsum into cement powder, and in sand and gravel production lines to grind aggregates into fine particles for high-quality concrete.

Key Factors to Consider When Selecting a Mining Ball Mill

Ore Properties: The hardness, viscosity, and particle size of the ore directly affect the selection of the ball mill. For hard ores, choose a grid-type or high-power ball mill with wear-resistant liner plates; for sticky ores, a wet-type ball mill is more suitable to prevent ore adhesion.

Grinding Fineness Requirement: If fine grinding is required (e.g., 0.074mm), an overflow-type ball mill is the best choice; for coarse grinding (e.g., 0.8mm), a grid-type ball mill is more appropriate.

Production Capacity: Determine the required processing capacity (T/h) based on your project’s daily ore output. Select a ball mill model with a capacity that matches or slightly exceeds your actual needs to avoid bottlenecks in the production line.

Wet or Dry Grinding: Choose a wet-type ball mill if the subsequent separation process requires slurry (e.g., flotation); select a dry-type ball mill if dry powder is needed or water is scarce.

Energy Consumption & Cost: Compare the energy consumption of different ball mill models. Modern energy-saving ball mills (e.g., with frequency conversion speed regulation) can reduce energy costs significantly. Also, consider the initial investment, maintenance costs, and spare parts supply when selecting a model.

Maintenance Tips for Mining Ball Mill

Regular Inspection & Lubrication: Inspect the ball mill’s transmission system (motor, reducer, bearing) daily for abnormal noise or overheating. Lubricate the bearings and gears regularly with high-quality lubricating oil to reduce friction and wear.

Replace Liner Plates & Steel Balls Timely: Liner plates and steel balls are vulnerable to wear during operation. Check their wear condition regularly and replace them when the wear exceeds the limit. Using high-chromium alloy liner plates and steel balls can extend their service life.

Clean the Mill Cylinder Regularly: Periodically clean the inside of the mill cylinder to remove ore residues and scale, which can affect grinding efficiency. For wet-type ball mills, flush the cylinder with water after shutdown to prevent slurry solidification.

Monitor Operating Parameters: Use monitoring systems to track key parameters such as rotating speed, feeding rate, and discharge particle size. Adjust these parameters in real time to maintain optimal grinding efficiency and prevent equipment overload.