Jaw crusher parts are the building blocks of this essential primary crushing equipment, used widely in mining, quarrying, and construction. Each component works in harmony to deliver compressive crushing force, ensuring efficient reduction of hard rocks and ores.

Understanding jaw crusher parts—their functions, materials, and wear characteristics—is critical for optimizing performance, extending equipment lifespan, and minimizing downtime.

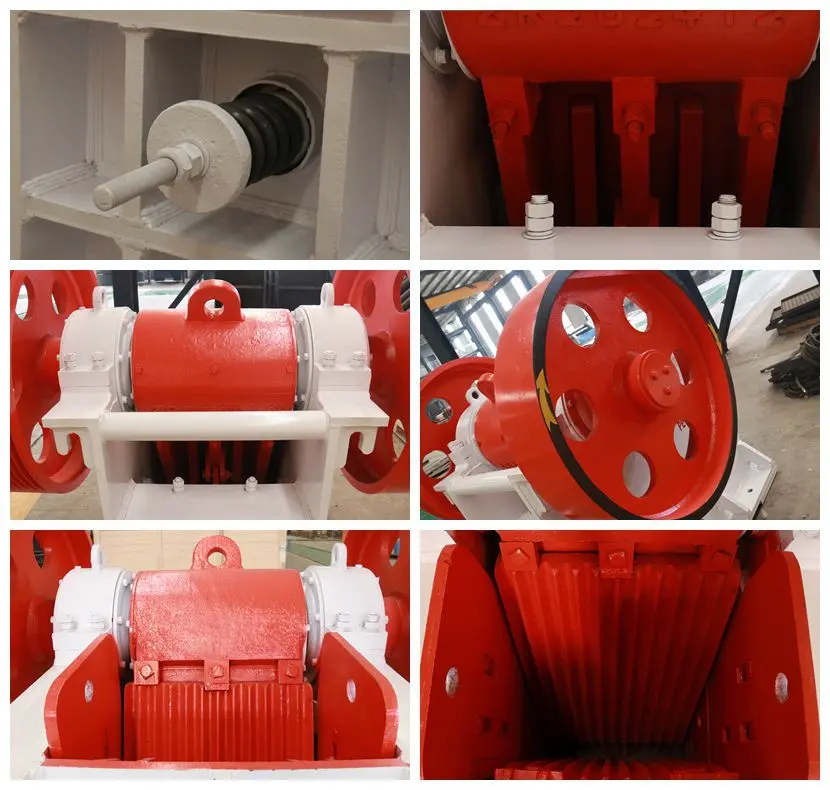

Core Jaw Crusher Parts & Their Functions

The primary jaw crusher parts responsible for crushing action are designed for durability and high impact resistance, as they bear the brunt of hard material processing.

1. Fixed Jaw Plate (Stationary Jaw)

The fixed jaw plate is a stationary component lined with a wear-resistant liner, forming one side of the crushing chamber. It is bolted to the crusher frame, providing a stable surface for material compression.

Made of high-manganese steel or alloy steel, it withstands repeated impact and abrasion from hard rocks like granite and basalt.

2. Movable Jaw Plate (Swinging Jaw)

The movable jaw plate is the moving component that exerts compressive force on materials, paired with the fixed jaw plate to form the crushing chamber. It is driven by the eccentric shaft to swing back and forth.

Its liner is also wear-resistant, and it requires regular inspection as it wears faster than the fixed jaw plate due to continuous movement.

3. Eccentric Shaft

The eccentric shaft is the "power core" of jaw crusher parts, connecting the motor to the movable jaw. It converts rotational energy from the motor into the reciprocating motion of the movable jaw.

Crafted from high-strength alloy steel, it is precision-machined to ensure stable rotation and minimize vibration.

4. Pitman (Connecting Rod)

The pitman links the eccentric shaft to the movable jaw, transmitting the eccentric shaft’s motion to drive the movable jaw’s swinging action. It acts as a force buffer, reducing impact on other components.

Heavy-duty designs with reinforced structures are used to handle high loads in large-scale jaw crushers.

5. Toggle Plate (肘板)

The toggle plate is a wear-resistant component that supports the movable jaw and controls the discharge gap. It also serves as a safety device—breaking under excessive load to protect other critical parts.

Made of manganese steel or cast iron, it is a consumable part that needs regular replacement.

Auxiliary Jaw Crusher Parts for Stable Operation

Beyond core crushing components, auxiliary jaw crusher parts ensure smooth, safe, and continuous operation of the equipment.

1. Crusher Frame

The frame is the base structure that houses all jaw crusher parts, providing structural stability and supporting crushing forces. It is made of heavy-duty cast steel or welded steel for rigidity.

Large frames are designed with ribbed structures to resist deformation under high pressure.

2. Drive System

The drive system includes the motor, pulley, belt, and reducer—components that power the eccentric shaft. It ensures consistent rotational speed for stable crushing performance.

V-belt drives are common in jaw crushers, offering flexibility and shock absorption.

3. Lubrication System

The lubrication system supplies oil to key jaw crusher parts like the eccentric shaft and bearings, reducing friction and wear. It prevents overheating and extends component service life.

Modern jaw crushers feature automatic lubrication systems for efficient, hands-free maintenance.

4. Discharge Adjustment Device

This component adjusts the gap between the fixed and movable jaw plates, controlling the size of the crushed output. It allows operators to adapt to different aggregate requirements.

Screw-type or hydraulic adjustment mechanisms are used, depending on the jaw crusher model.

5. Safety Guards

Safety guards are essential auxiliary jaw crusher parts, covering moving components like pulleys and belts to prevent accidents in industrial settings.

They comply with occupational safety standards, ensuring worker protection during operation and maintenance.

Materials & Wear Characteristics of Jaw Crusher Parts

The lifespan of jaw crusher parts depends on their material selection, as they operate in abrasive and high-impact environments.

Wear parts (jaw plates, toggle plates) use high-manganese steel (Mn13, Mn18) for its excellent wear resistance, while structural parts (frame, eccentric shaft) use alloy steel for strength.

Maintenance Tips for Jaw Crusher Parts

Proper maintenance of jaw crusher parts is key to reducing downtime and optimizing equipment efficiency.

Regular Inspection: Check wear parts for abrasion weekly, replacing them when wear exceeds 50% of their thickness.

Lubrication Management: Monitor oil levels and quality, replacing lubricant every 2,000-3,000 operating hours.

Tighten Fasteners: Inspect bolts on jaw plates and frame regularly, as vibration can loosen connections.

Align Components: Ensure the eccentric shaft and drive system are properly aligned to avoid uneven wear.

Conclusion

Jaw crusher parts work synergistically to deliver reliable primary crushing performance, with core components handling the crushing action and auxiliary parts ensuring stability and safety.

By understanding the functions, materials, and maintenance of jaw crusher parts, operators can extend equipment lifespan, reduce costs, and maintain consistent production in mining and construction workflows.