In the field of mineral processing, construction waste recycling, and aggregate production, crushing equipment plays a pivotal role. Among the various types of crushers, cone crushers and impact crushers are two widely used models, each with unique characteristics and application scenarios. Understanding the difference between cone crusher and impact crusher is essential for enterprises and project managers to make rational equipment selection, optimize production efficiency, and reduce operational costs. This article will systematically compare the two crushers from multiple perspectives, providing a comprehensive reference for your equipment selection.

1. Working Principle: The Fundamental Distinction

The core difference between cone crusher and impact crusher first lies in their distinct working principles, which directly determine their crushing effects and applicable materials.

1.1 Cone Crusher: Lamination Crushing Based on Compression

Cone crushers adopt the working principle of compression and lamination crushing. The equipment mainly consists of a fixed cone (concave) and a movable cone (mantle). When the motor drives the eccentric sleeve to rotate through the transmission device, the movable cone will make a periodic swing around the central axis. When the movable cone approaches the fixed cone, the materials between the two cones are squeezed, crushed, and sheared by the combined force, thereby achieving the crushing purpose. When the movable cone moves away from the fixed cone, the crushed materials that meet the particle size requirements will fall from the discharge port under the action of gravity.

This lamination crushing method enables the materials to be crushed not only by the pressure between the cones but also by the mutual friction and collision between the materials, which helps to improve the crushing efficiency and the shape of the finished product to a certain extent.

1.2 Impact Crusher: Impact Crushing Driven by High-Speed Impact

Impact crushers rely on high-speed impact force to crush materials, and their working principle is more dynamic. The key component of the equipment is the rotor with impact hammers (or blow bars). When the motor drives the rotor to rotate at high speed, the impact hammers on the rotor will hit the materials fed into the crushing cavity with great kinetic energy. The materials are first crushed by the primary impact of the hammers, then rebound to the impact plate (breaker plate) in the cavity, and are crushed again by the secondary impact. After repeated impacts, collisions, and rebounds, the materials are crushed to the required particle size and discharged from the lower part of the equipment.

The high-speed impact mode makes the impact crusher have a strong crushing capacity for materials with brittle properties, and the finished product has a more irregular shape, which is conducive to improving the bonding performance of aggregates in concrete.

2. Core Structure: Different Designs for Different Demands

The structural design of cone crusher and impact crusher is closely related to their working principles, and the differences in structure also lead to differences in their maintenance difficulty and service life.

2.1 Cone Crusher: Robust Structure for Heavy Loads

The structure of the cone crusher is relatively complex and robust, mainly including the frame, transmission device, eccentric sleeve, movable cone, fixed cone, hydraulic system, and lubrication system. The fixed cone is fixed on the frame, while the movable cone is connected to the eccentric sleeve. The hydraulic system is an important part of the modern cone crusher, which can realize the adjustment of the discharge port, the overload protection of the equipment, and the maintenance of the movable cone. The lubrication system ensures the smooth operation of various moving parts, reduces wear, and prolongs the service life of the equipment.

Due to the need to bear large compressive force, the key components such as the movable cone and fixed cone of the cone crusher are usually made of high-strength alloy steel, which has good wear resistance and impact resistance.

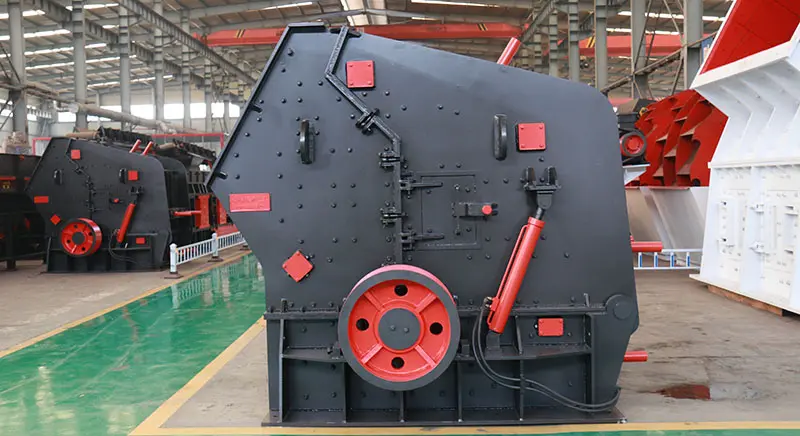

2.2 Impact Crusher: Simple Structure for Easy Maintenance

Compared with the cone crusher, the structure of the impact crusher is simpler, mainly composed of the frame, rotor, impact hammer, impact plate, adjustment device, and feeding and discharging device. The rotor is the core rotating part, and the impact hammers are evenly installed on the rotor. The adjustment device can adjust the distance between the impact plate and the rotor to control the particle size of the finished product. Some advanced impact crushers also adopt a hydraulic adjustment system, which makes the adjustment more convenient and efficient.

The impact hammer and impact plate are the vulnerable parts of the impact crusher. They are usually made of wear-resistant materials such as high manganese steel. The replacement of these vulnerable parts is relatively simple, which can reduce the maintenance time and labor cost.

3. Performance Characteristics: Contrasts in Efficiency and Quality

When comparing cone crusher and impact crusher, their performance characteristics such as crushing ratio, production capacity, finished product quality, and energy consumption are important indicators that cannot be ignored.

3.1 Crushing Ratio

The crushing ratio refers to the ratio of the particle size of the raw material to the particle size of the finished product, which reflects the crushing capacity of the equipment. The impact crusher has a higher crushing ratio, generally between 10-30, because the high-speed impact force can fully crush the materials. The cone crusher has a relatively lower crushing ratio, usually between 5-15, and it is more suitable for medium and fine crushing operations after coarse crushing.

3.2 Production Capacity

The production capacity of the crusher is affected by factors such as the model, feed particle size, material hardness, and discharge particle size. Under the condition of processing materials with the same hardness and similar feed particle size, the large and medium-sized cone crushers have higher production capacity, which can reach hundreds or even thousands of tons per hour, making them suitable for large-scale production lines. The production capacity of the impact crusher is relatively lower, generally between several tens to several hundred tons per hour, which is more suitable for medium and small-scale production projects.

3.3 Finished Product Quality

The quality of the finished product is mainly evaluated by indicators such as particle shape, gradation, and content of needle and flake particles. The impact crusher produces finished products with good particle shape, mostly cubic, low content of needle and flake particles (generally less than 10%), and uniform gradation, which meets the high requirements of high-grade highways, railways, and concrete prefabricated parts for aggregates. The finished product of the cone crusher has a relatively regular shape, but the content of needle and flake particles is slightly higher than that of the impact crusher, which is suitable for projects with general requirements for aggregate shape.

3.4 Energy Consumption and Wear Resistance

In terms of energy consumption, when processing hard materials (such as granite, basalt), the cone crusher has lower unit energy consumption because the lamination crushing method is more energy-efficient. The impact crusher consumes more energy when processing hard materials, and the wear of vulnerable parts is faster, which increases the operating cost. For soft and medium-hard materials (such as limestone, coal gangue), the energy consumption gap between the two is smaller, and the impact crusher can give full play to its advantages of high crushing ratio.

4. Applicable Materials and Scenarios: Matching the Right Crusher to the Task

The difference between cone crusher and impact crusher in working principle and performance determines their different applicable ranges of materials and application scenarios.

4.1 Cone Crusher: Ideal for Hard and Abrasive Materials

Due to its robust structure and compression crushing mode, the cone crusher is especially suitable for crushing hard, medium-hard, and abrasive materials, such as granite, basalt, diabase, quartzite, iron ore, copper ore, and other metal and non-metal ores. Its main application scenarios include: coarse crushing, medium crushing, and fine crushing in metal mines and non-metal mines; aggregate production in large-scale construction projects such as hydropower stations, highways, and railways; and crushing operations in cement plants and building material factories.

4.2 Impact Crusher: Suitable for Brittle and Medium-Soft Materials

The impact crusher is more suitable for crushing brittle and medium-soft materials with low abrasive properties, such as limestone, dolomite, marble, gypsum, coal, coal gangue, and construction waste. Its application scenarios mainly include: aggregate production for highways, urban roads, and concrete mixing stations; crushing of coal and coal gangue in coal mines; recycling of construction waste (such as concrete blocks, brick fragments); and fine crushing of non-metallic minerals with low hardness.

5. How to Choose: Key Factors to Consider

Choosing between a cone crusher and an impact crusher requires comprehensive consideration of multiple factors to ensure that the selected equipment can meet the actual production needs.

5.1 Material Properties

This is the most critical factor. If the processed material is hard (Mohs hardness ≥ 7) and has strong abrasiveness, such as granite and basalt, the cone crusher is the first choice; if the material is brittle and medium-soft (Mohs hardness ≤ 6), such as limestone and construction waste, the impact crusher can give full play to its advantages.

5.2 Requirements for Finished Products

If the project has high requirements for the particle shape and gradation of the finished product, such as high-grade highways and prefabricated concrete parts, the impact crusher is more suitable; if the requirements for particle shape are general, and the focus is on production capacity and crushing efficiency, the cone crusher is a better choice.

5.3 Production Scale and Capacity Requirements

For large-scale production lines with high capacity requirements (more than 500 tons per hour), large cone crushers are more suitable; for medium and small-scale production projects with capacity requirements below 300 tons per hour, impact crushers are more economical and practical.

5.4 Investment and Operating Costs

The initial investment of the cone crusher is generally higher than that of the impact crusher of the same specification, but its vulnerable parts have a longer service life and lower wear cost when processing hard materials. The initial investment of the impact crusher is lower, but the replacement frequency of vulnerable parts is higher when processing hard materials, which increases the operating cost. Therefore, it is necessary to comprehensively calculate the total cost of the whole service life cycle when making a choice.

Final Thoughts: Making the Right Choice for Your Crushing Needs

At the end of the day, cone crushers and impact crushers aren’t “better” or “worse”—they’re designed for distinct roles, shaped by their unique working mechanisms and structural strengths. For operations tackling hard, abrasive materials like granite or basalt, or large-scale projects needing consistent high throughput, the cone crusher’s robust build and wear-resistant design shine as a reliable workhorse. On the flip side, when your priority is crisp, cubic aggregate shapes (critical for high-grade concrete or highway projects) or processing brittle, medium-soft materials like limestone or construction waste, the impact crusher’s high crushing ratio and easy maintenance become unbeatable advantages. The key to smart equipment selection lies in aligning these strengths with your specific project goals—whether that’s material hardness, finished product quality, production scale, or long-term operating costs. By matching the crusher to the task at hand, you’ll not only optimize efficiency but also maximize the value of every ton of material you process.