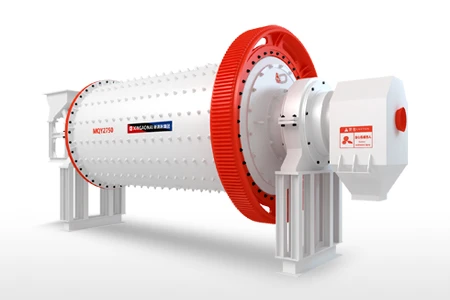

Ball mill parts are the essential components that power this widely used grinding equipment in mining, cement, and chemical industries. Each part works synergistically to grind raw materials into fine powders or slurries, supporting subsequent processing steps like beneficiation and mixing.

Understanding ball mill parts—their roles, material selections, and wear patterns—is crucial for optimizing grinding efficiency, extending equipment lifespan, and reducing operational downtime.

Core Ball Mill Parts & Their Functions

The core ball mill parts are responsible for the grinding action, designed to withstand high impact, abrasion, and rotational stress during operation.

1. Ball Mill Cylinder (Shell)

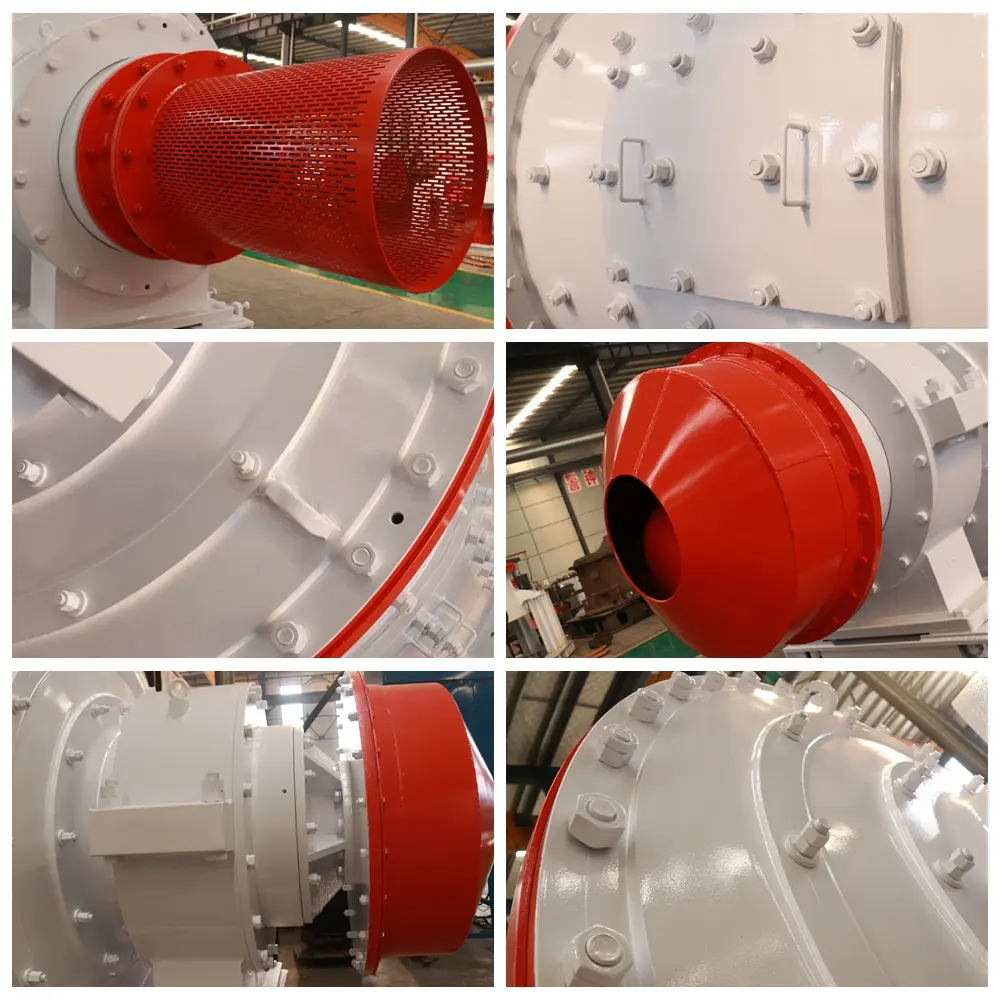

The cylinder (shell) is the main body of the ball mill, a rotating drum made of thick carbon steel or alloy steel plates welded together. It holds the grinding media and raw materials, providing the grinding chamber.

Its inner surface is lined with wear-resistant liners to protect the cylinder from abrasion, extending the service life of this critical component.

2. Grinding Media

Grinding media are the wear parts that deliver the grinding force, typically steel balls, steel rods, or ceramic balls. Their size and quantity vary based on the desired fineness of the final product.

Steel balls (made of high-carbon steel or stainless steel) are the most common, as they offer excellent impact resistance and grinding efficiency for hard materials.

3. Liners

Liners are detachably mounted on the inner wall of the cylinder, acting as a protective barrier between the cylinder and grinding media. They also enhance grinding efficiency by optimizing the motion of the media.

Common liner materials include high-manganese steel, rubber, and ceramic—rubber liners reduce noise, while manganese steel liners excel in abrasion resistance.

4. Diaphragm (Partition Plate)

For multi-compartment ball mills, diaphragms divide the cylinder into separate grinding chambers. Each chamber uses different-sized grinding media to achieve gradual refinement of materials.

They feature holes to allow materials to flow from one compartment to the next, ensuring sequential grinding and uniform fineness.

Auxiliary Ball Mill Parts for Stable Operation

Auxiliary ball mill parts support the core grinding process, ensuring smooth rotation, safe operation, and efficient material handling.

1. Drive System

The drive system is a key auxiliary component, consisting of a motor, reducer, coupling, and pinion gear. It converts electrical energy into rotational energy to drive the cylinder.

Large ball mills often use a girth gear and pinion drive, while small models may adopt a direct drive for simplicity.

2. Bearings

Bearings support the rotating cylinder, reducing friction between the cylinder and fixed components. They are typically spherical roller bearings or sliding bearings, designed to handle heavy radial and axial loads.

Proper lubrication of bearings is critical to prevent overheating and premature wear.

3. Lubrication System

The lubrication system supplies oil or grease to key ball mill parts like bearings and the drive system, minimizing friction and wear. It ensures smooth operation and extends component service life.

Modern ball mills are equipped with automatic lubrication systems that monitor oil levels and pressure for optimal performance.

4. Feeding & Discharging Devices

Feeding devices (e.g., feed hoppers, spiral feeders) deliver raw materials into the cylinder evenly, preventing overloading and ensuring consistent grinding.

Discharging devices (e.g., grid plates, overflow pipes) remove the ground materials, with designs tailored to dry or wet grinding processes.

5. Foundation & Frame

The frame and foundation provide structural support for the entire ball mill, absorbing vibration generated during rotation. They are made of reinforced concrete or heavy-duty steel to ensure stability.

Proper foundation design is essential to avoid equipment displacement and reduce noise.

Material Selection for Ball Mill Parts

Material selection for ball mill parts depends on their function and operating conditions, with a focus on wear resistance, strength, and durability.

Wear parts (liners, grinding media) use high-manganese steel, ceramic, or rubber, while structural parts (cylinder, frame) use carbon steel or alloy steel for rigidity.

Maintenance Tips for Ball Mill Parts

Regular maintenance of ball mill parts is key to maximizing equipment efficiency and minimizing downtime in industrial settings.

Inspect Wear Parts: Check liners and grinding media weekly for abrasion; replace liners when wear exceeds 60% and replenish grinding media as needed.

Lubrication Management: Monitor lubricant levels and quality, replacing oil every 3,000-5,000 operating hours to protect bearings and drive components.

Check Alignment: Ensure the drive system and cylinder are properly aligned to avoid uneven wear and vibration.

Clean Components: Remove material buildup from feeding/discharging devices and diaphragms to maintain smooth material flow.

Conclusion

Ball mill parts work in harmony to deliver reliable grinding performance, with core components handling the grinding action and auxiliary parts ensuring stability and efficiency.

By understanding the functions, materials, and maintenance of ball mill parts, operators can optimize grinding processes, extend equipment lifespan, and reduce operational costs in mining, cement, and chemical industries.