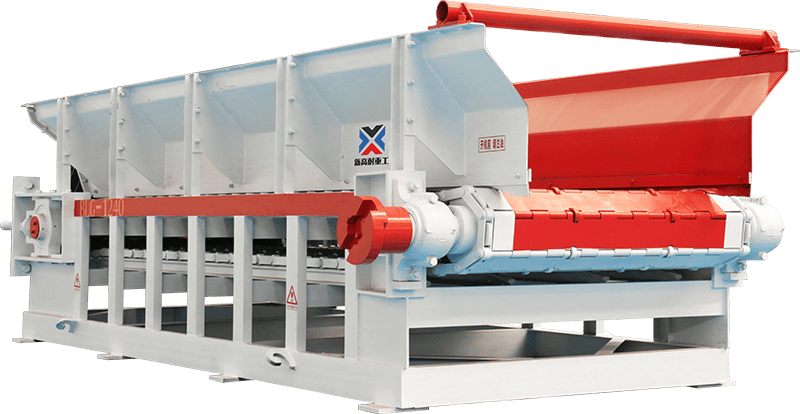

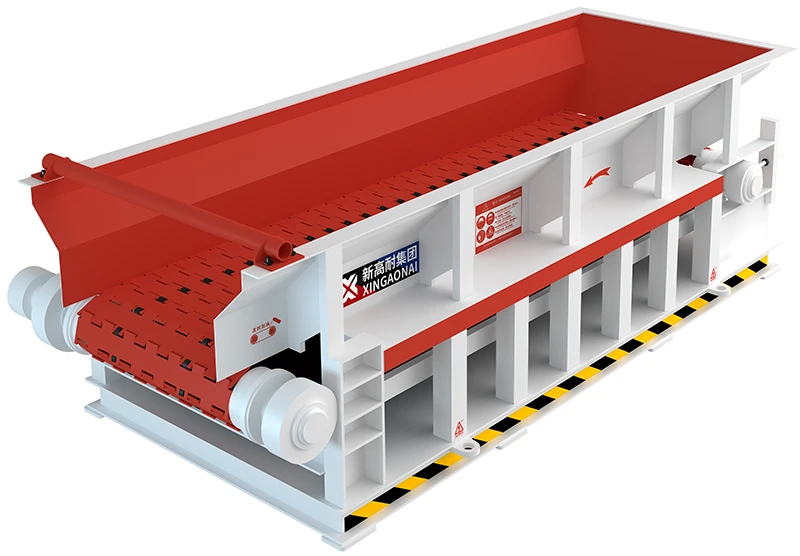

Apron feeder parts are the essential components of heavy-duty apron feeders, critical for conveying bulk, abrasive materials like ore, rock, and aggregates in mining, quarrying, and cement industries. These parts work synergistically to ensure continuous, stable material feeding to crushers, grinders, or other processing equipment.

Understanding apron feeder parts—their roles, wear characteristics, and maintenance needs—is vital for minimizing downtime, extending equipment lifespan, and optimizing material handling efficiency.

Core Apron Feeder Parts & Their Functions

Core apron feeder parts bear the brunt of material weight and abrasion, designed for high strength, durability, and impact resistance to handle harsh working conditions.

1. Apron Plates (Panels)

Apron plates (or panels) are the primary conveying components, forming a continuous belt-like surface to carry bulk materials. They are made of thick, wear-resistant steel or alloy plates, often with reinforced edges.

Each plate is connected to adjacent ones via hinges or bolts, ensuring flexibility to adapt to the feeder’s path while maintaining a tight seal to prevent material leakage.

2. Chain Assemblies

Chain assemblies are the driving force for apron plate movement, consisting of heavy-duty roller chains, pins, and bushings. They connect the apron plates to the drive system, transmitting rotational energy.

High-strength alloy steel chains are commonly used, as they withstand heavy loads and repeated tension without deformation or breakage.

3. Drive System

The drive system is the power core of apron feeder parts, comprising a motor, reducer, sprockets, and couplings. It converts electrical energy into linear motion to move the apron plate chain.

Sprockets mesh with the chain to drive movement, while the reducer adjusts speed to match material feeding requirements (typically 0.1-0.5 m/s).

4. Idlers (Support Rollers)

Idlers (support rollers) support the apron plate chain and the weight of conveyed materials, reducing friction and ensuring smooth movement. They are installed along the feeder’s length, both on the carrying and return sides.

Wear-resistant roller surfaces and sealed bearings extend the service life of this critical apron feeder part.

5. Tensioning Device

The tensioning device maintains optimal tension in the chain assembly, preventing slack that can cause chain skipping or apron plate misalignment. It is usually a hydraulic or screw-type mechanism.

Regular adjustment of the tensioning device ensures stable operation and reduces wear on chains and sprockets.

Auxiliary Apron Feeder Parts for Stable Operation

Auxiliary apron feeder parts support core conveying functions, enhancing safety, reducing wear, and ensuring consistent performance in industrial settings.

1. Lubrication System

The lubrication system supplies grease or oil to key apron feeder parts like chains, sprockets, and bearings, minimizing friction and abrasion. It prevents overheating and extends component service life.

Automatic lubrication systems are common in modern apron feeders, ensuring precise, continuous lubrication without manual intervention.

2. Safety Guards

Safety guards are essential auxiliary parts, covering moving components (chains, sprockets, drive system) to prevent accidents and protect workers from injury.

They comply with industrial safety standards and are designed for easy access during maintenance.

3. Feed Hopper & Chute

The feed hopper collects bulk materials and guides them evenly onto the apron plates, preventing uneven loading and material buildup. The chute ensures smooth material transfer to downstream equipment.

Wear-resistant liners inside the hopper and chute protect against abrasion from hard materials.

4. Frame & Base

The frame and base provide structural support for all apron feeder parts, absorbing vibration and material impact. They are made of heavy-duty welded steel or cast iron for rigidity.

Reinforced designs ensure the frame can withstand the weight of the feeder and conveyed materials without deformation.

5. Wear Liners

Wear liners are attached to apron plates, hoppers, and chutes, acting as a protective barrier against abrasive materials. They are replaceable, reducing the need to repair or replace expensive core components.

Common liner materials include high-manganese steel, rubber, and ceramic, selected based on material abrasiveness.

Material Selection for Apron Feeder Parts

Material selection for apron feeder parts depends on their function and operating conditions, prioritizing wear resistance, strength, and corrosion resistance.

Core parts (apron plates, chains) use alloy steel or high-manganese steel; auxiliary parts (liners) use rubber or ceramic; structural parts (frame) use carbon steel for rigidity.

Maintenance Tips for Apron Feeder Parts

Proper maintenance of apron feeder parts is key to maximizing equipment uptime and reducing operational costs in heavy-industry settings.

Inspect Wear Parts: Check apron plates, chains, and liners weekly for abrasion; replace worn plates when thickness decreases by 50% and replenish chains if links are damaged.

Lubrication Management: Monitor lubricant levels and quality, replacing grease every 2,000-3,000 operating hours to protect moving components.

Adjust Tension: Regularly check chain tension and adjust the tensioning device to prevent slack, misalignment