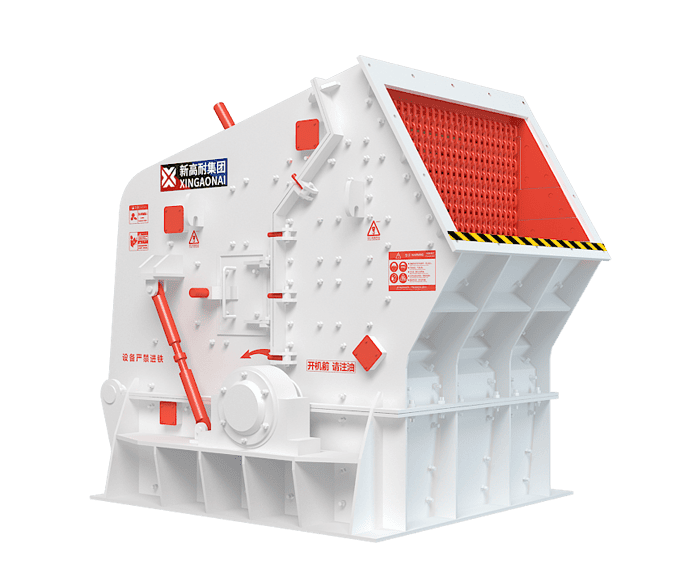

In the world of aggregate production, mining, and construction, impact crushers are celebrated for their ability to turn large, unrefined materials into usable aggregates efficiently. But for many industry professionals and newcomers alike, a key question lingers: How does an impact crusher work? Unlike jaw crushers that rely on compression or cone crushers that use squeezing force, impact crushers operate on a unique impact-based mechanism. This article breaks down their working principle, core components that drive the process, a detailed step-by-step operation, and factors that influence their performance—providing a complete answer to this critical question.

The Core Working Principle: Impact vs. Compression

To understand how an impact crusher works, it’s first essential to distinguish its operating principle from other common crushers. Most traditional crushers (e.g., jaw, cone) use compressive force: they clamp materials between two hard surfaces and apply pressure until the material fractures. Impact crushers, by contrast, use kinetic energy and high-speed impact to break down materials.

The principle hinges on a simple yet powerful concept: a rotating rotor equipped with heavy-duty blow bars gains kinetic energy as it spins. When raw materials enter the crusher, the fast-moving blow bars strike the material with immense force, shattering it into smaller pieces. These fragmented pieces then collide with stationary impact plates (breaker plates) and even with other material particles—creating secondary and tertiary crushing actions. This multi-stage impact process ensures the material is reduced to the desired size and shape, often producing cubical aggregates ideal for construction.

Key Components That Power an Impact Crusher’s Operation

An impact crusher’s ability to function relies on several interconnected components, each playing a vital role in the crushing process. Without these parts working in harmony, the impact mechanism would fail to deliver efficient results. Here are the critical components:

Rotor: The “heart” of the impact crusher. The rotor is a thick, robust shaft fitted with blow bars (or hammers) around its circumference. Driven by a high-horsepower motor, it rotates at speeds ranging from 500 to 1,500 RPM—generating the kinetic energy needed for impact. The rotor’s weight and speed directly determine the crusher’s crushing capacity and force.

Blow Bars: Wear-resistant metal components (usually made of manganese steel or high-chrome alloys) attached to the rotor. They are the point of contact between the rotor and the raw material, delivering the initial impact that breaks the material. Blow bars are replaceable, as they wear down over time due to constant contact with hard materials.

Impact Plates (Breaker Plates): Stationary steel plates positioned around the rotor. After the initial impact from the blow bars, fragmented materials are thrown toward these plates at high speed. The collision with the impact plates causes secondary crushing, refining the material size. Many models feature adjustable impact plates, allowing operators to control the gap between the plates and the rotor—directly regulating the final product size.

Feed Hopper & Vibrating Feeder: The feed hopper stores raw materials (e.g., limestone, granite, concrete debris) and channels them into the crusher. A vibrating feeder ensures a consistent, uniform flow of material to the rotor—preventing overloading, reducing wear, and optimizing crushing efficiency.

Grinding Chamber: The enclosed space where all crushing actions occur. Its design (e.g., size, shape, placement of impact plates) influences how materials move and collide, affecting both product quality and throughput.

Discharge Conveyor: Removes the final crushed product from the grinding chamber, enabling continuous operation. Some conveyors include screens to separate oversize particles, which are then recycled back into the crusher for further processing.

Step-by-Step: How an Impact Crusher Operates

Now that we’ve covered the principle and components, let’s walk through the exact sequence of operations that answers “How does an impact crusher work?” From material entry to final discharge, each step is a critical part of the process:

Step 1: Material Feeding – Consistent Supply to the Crusher

The process begins with raw materials (often 10–50 cm in size) being loaded into the feed hopper via an excavator or conveyor. The vibrating feeder attached to the hopper regulates the material flow, ensuring a steady stream enters the grinding chamber. This consistency is vital: too much material can overload the rotor and motor, while too little reduces productivity.

Step 2: Initial Impact – Rotor and Blow Bars Deliver the First Break

As material enters the grinding chamber, it meets the high-speed rotating rotor. The blow bars mounted on the rotor strike the material with extreme force—transferring the rotor’s kinetic energy into the material. This initial impact shatters the material into smaller fragments (typically 5–20 cm), breaking it down to a size that can undergo further processing.

Step 3: Secondary Crushing – Collision with Impact Plates

The fragmented material is thrown outward by the rotor’s centrifugal force, flying toward the stationary impact plates. The collision with these plates delivers a second crushing blow, reducing the material size even further. If the impact plates are adjustable, operators can tweak the gap between the plates and the rotor to control how fine the material becomes here.

Step 4: Tertiary Crushing – Particle-to-Particle Impact (Optional)

In many modern impact crushers, a third crushing stage occurs: fragmented particles collide with each other mid-air or against other material in the chamber. This “particle-on-particle” impact is gentler than metal-on-material contact, reducing wear on blow bars and impact plates while producing more uniform, cubical aggregates—ideal for high-quality concrete or asphalt.

Step 5: Sizing and Discharge – Separating Finished Product

After the multiple impact stages, material that meets the desired size (set by the impact plate gap) falls through the gap between the rotor and the plates. It then exits the grinding chamber onto the discharge conveyor, which transports it to a stockpile or next processing stage. Any oversize particles that don’t fit through the gap are retained in the chamber, where they undergo additional impacts until they reach the required size.

Factors That Influence an Impact Crusher’s Performance

While the basic working process is consistent, several factors can alter how effectively an impact crusher operates. Understanding these helps optimize performance and answer “How does an impact crusher work best?”:

Material Properties: Hardness (e.g., granite vs. limestone) and brittleness affect impact force requirements. Brittle materials shatter more easily, while hard materials require higher rotor speeds and more durable blow bars.

Rotor Speed: Higher speeds increase kinetic energy, delivering more force for breaking hard materials. Lower speeds are better for softer materials to avoid over-crushing.

Impact Plate Gap: A smaller gap produces finer products, while a larger gap increases throughput (but yields coarser aggregates).

Blow Bar Condition: Worn blow bars reduce impact force, leading to inefficient crushing and larger product sizes. Regular replacement is key.

FAQs: Clarifying Common Questions About Impact Crusher Operation

Q1: Do all impact crushers work the same way?

No—there are two main types: Horizontal Shaft Impact (HSI) crushers and Vertical Shaft Impact (VSI) crushers. HSIs use a horizontal rotating rotor (as described above) and are common for secondary crushing. VSIs have a vertical rotor that spins material outward into a stationary anvil, relying more on particle-on-particle impact for tertiary crushing.

Q2: Can impact crushers handle wet materials?

Yes, but with caution. Wet materials can clump, reducing throughput and causing buildup in the grinding chamber. Many models have features like heated chambers or anti-clogging plates to mitigate this issue.

Conclusion

The answer to “How does an

impact crusher work?” lies in its simple yet effective impact-based mechanism: a high-speed rotor delivers initial force, impact plates provide secondary crushing, and particle collisions refine the product. By understanding its core components—rotor, blow bars, impact plates—and the step-by-step process from feeding to discharge, industry professionals can optimize operation, reduce downtime, and ensure consistent, high-quality aggregates. Whether used in mining, construction, or waste recycling, the impact crusher’s ability to combine efficiency and versatility makes it a cornerstone of modern material processing.