A vibrating feeder motor plays a critical role in modern industrial material handling systems. It is widely used in mining, construction, metallurgy, cement, chemical processing, food production, and many other industries that require controlled and continuous material feeding. By generating stable and adjustable vibration forces, a vibrating feeder motor ensures that bulk materials are transported efficiently, evenly, and safely along the production line.

What Is a Vibrating Feeder Motor?

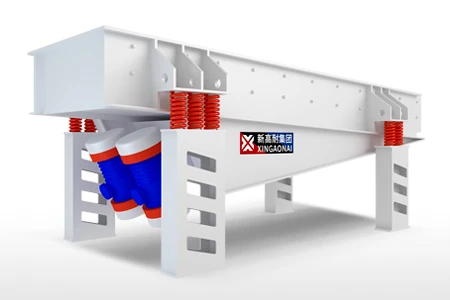

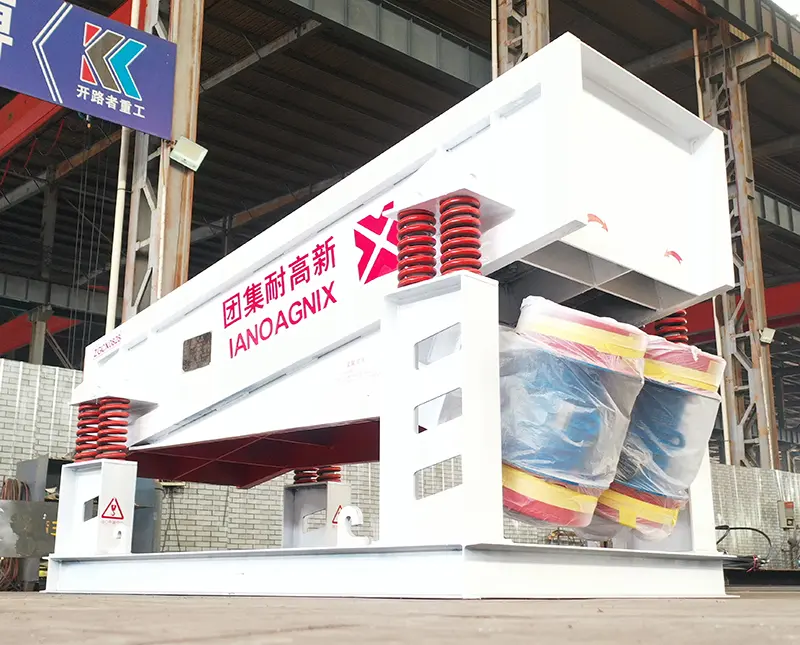

A vibrating feeder motor is a specialized electric motor designed to produce vibration through adjustable eccentric weights mounted on its shaft. When the motor rotates, the eccentric blocks create centrifugal force, which generates vibration. This vibration drives the feeder tray or chute to move materials forward in a controlled manner.

Unlike standard electric motors, a vibrating feeder motor is built to withstand high-frequency vibration and continuous operation. It features reinforced bearings, a durable housing, and optimized internal components to ensure long service life under demanding working conditions.

How Does a Vibrating Feeder Motor Work?

The working principle of a vibrating feeder motor is based on centrifugal force. When powered on, the motor shaft rotates at high speed. The eccentric weights attached to both ends of the shaft generate vibration force. By adjusting the angle or position of these weights, operators can control the amplitude and vibration strength.

In a typical vibrating feeder system, two vibrating feeder motors are installed symmetrically. They rotate in opposite directions, which creates a linear vibration pattern. This linear motion allows materials to move steadily along the feeder tray without significant spillage or blockage.

The ability to adjust vibration intensity makes the vibrating feeder motor highly versatile. It can handle fine powders, granular materials, and even larger bulk materials with consistent feeding accuracy.

Key Features of a High-Quality Vibrating Feeder Motor

When selecting a vibrating feeder motor, several key features should be considered:

Adjustable Excitation Force

A reliable vibrating feeder motor allows precise adjustment of centrifugal force, ensuring accurate feeding rates for different materials.High Durability

Industrial environments often involve dust, moisture, and heavy loads. A high-quality vibrating feeder motor is designed with sealed bearings and robust protection to prevent damage.Energy Efficiency

Modern vibrating feeder motors are engineered to deliver strong vibration with optimized energy consumption, reducing operating costs.Low Noise and Stable Operation

Advanced balancing technology ensures smoother performance and lower noise levels, which improves workplace safety and comfort.Easy Installation and Maintenance

Compact design and simple structure make the vibrating feeder motor easy to install, inspect, and maintain.

Applications of Vibrating Feeder Motors

A vibrating feeder motor is essential in many industrial processes. In mining operations, it ensures continuous feeding of ores into crushers and screening equipment. In cement plants, it regulates the flow of raw materials. In the food industry, it enables controlled handling of grains and powders while maintaining hygiene standards.

In addition, recycling facilities use vibrating feeder motors to sort and transport materials efficiently. Chemical plants rely on them for precise feeding of raw materials into reactors. Their adaptability makes vibrating feeder motors a core component in automated production lines.

Advantages of Using a Vibrating Feeder Motor

Using a vibrating feeder motor offers several operational advantages:

Consistent material flow

Reduced manual labor

Improved production efficiency

Lower risk of material blockage

Enhanced automation compatibility

Because the vibration force can be finely tuned, operators can maintain a stable feeding rate even when material properties change. This flexibility significantly improves process control.

Maintenance Tips for Vibrating Feeder Motors

To ensure long-term performance, regular maintenance of a vibrating feeder motor is essential. Operators should periodically check bolt tightness, bearing temperature, lubrication condition, and electrical connections. Dust and debris should be cleaned regularly to prevent overheating.

Proper alignment during installation also plays a crucial role. Incorrect mounting may cause abnormal vibration or premature wear. By following manufacturer guidelines, users can extend the service life of their vibrating feeder motor and reduce downtime.

Choosing the Right Vibrating Feeder Motor Supplier

Selecting a reliable supplier is just as important as choosing the right model. A professional manufacturer should provide technical support, customization options, and after-sales service. Certifications such as ISO standards and compliance with international safety regulations indicate product quality and reliability.

When comparing suppliers, consider motor power, voltage range, protection grade, and vibration force specifications. A well-matched vibrating feeder motor ensures optimal performance and cost efficiency.

Conclusion

The vibrating feeder motor is a vital component in industrial feeding systems. Its ability to generate adjustable and stable vibration makes it indispensable for material handling applications. From mining and cement production to food processing and recycling, vibrating feeder motors contribute to higher productivity and improved process control.

By selecting a high-quality vibrating feeder motor and maintaining it properly, businesses can achieve reliable operation, energy efficiency, and long-term cost savings.