An industrial tank agitator is a critical piece of equipment used to mix, blend, and homogenize liquids or slurries in various industrial processes. It is widely applied in chemical processing, mining, wastewater treatment, food production, and pharmaceutical industries. By providing controlled and efficient mixing, industrial tank agitators help improve product quality and process consistency.

How an Industrial Tank Agitator Works

An industrial tank agitator operates by rotating an impeller inside a tank, creating fluid movement that promotes uniform mixing. The rotational energy generates flow patterns that distribute solids, dissolve additives, and maintain suspension. Different agitator designs are selected based on viscosity, tank size, and process requirements.

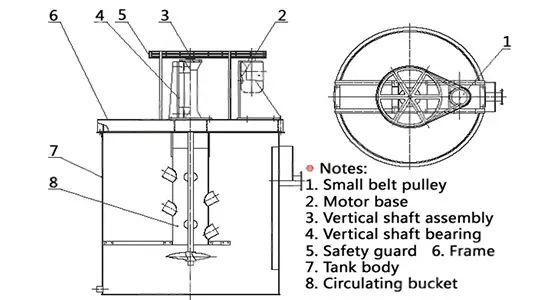

Main Components of an Industrial Tank Agitator

Motor and Drive System

The motor supplies the power needed to rotate the agitator shaft. Gear reducers or variable speed drives are often used to control mixing intensity and optimize energy consumption.

Agitator Shaft

The shaft transmits torque from the motor to the impeller. It must be strong enough to handle continuous operation and resistant to corrosion, especially in aggressive chemical environments.

Impeller

The impeller is the core mixing element. Common impeller types include paddle, turbine, propeller, and anchor designs. Each type produces different flow characteristics to suit specific mixing tasks.

Tank and Mounting Structure

The tank provides the mixing space, while the mounting structure ensures stable installation. Proper alignment and sealing are essential for safe and efficient operation.

Types of Industrial Tank Agitators

Industrial tank agitators can be classified based on mixing requirements:

Top-entry agitators for general-purpose mixing

Side-entry agitators for large storage tanks

Bottom-entry agitators for hygienic or high-shear applications

Selecting the right type helps improve mixing efficiency and reduce operating costs.

Applications of Industrial Tank Agitators

Industrial tank agitators are widely used in:

Chemical and petrochemical processing

Mineral processing and flotation systems

Wastewater treatment plants

Food and beverage production

Pharmaceutical and cosmetic manufacturing

Each application may require specific materials, sealing systems, and impeller designs.

Advantages of Using an Industrial Tank Agitator

An industrial tank agitator offers several benefits:

Uniform mixing and improved product quality

Reduced processing time

Lower energy consumption with optimized designs

Reliable operation under continuous working conditions

These advantages make industrial tank agitators essential in modern industrial production.

How to Choose the Right Industrial Tank Agitator

When selecting an industrial tank agitator, factors such as tank volume, material viscosity, mixing objectives, and operating environment should be considered. Proper selection ensures efficient performance and long service life.

Conclusion

An industrial tank agitator plays a vital role in achieving efficient and consistent mixing across various industries. Understanding its structure, working principles, and applications helps operators select the right solution for reliable and cost-effective production.