A multi-cylinder hydraulic cone crusher is an advanced crushing machine widely used in mining, metallurgy, construction, and aggregate production. Its design focuses on high crushing efficiency, consistent output quality, and superior automation. Understanding how it works helps users select the right equipment and optimize performance. Below is a detailed explanation suitable for SEO and technical readers.

What Is a Multi-Cylinder Hydraulic Cone Crusher?

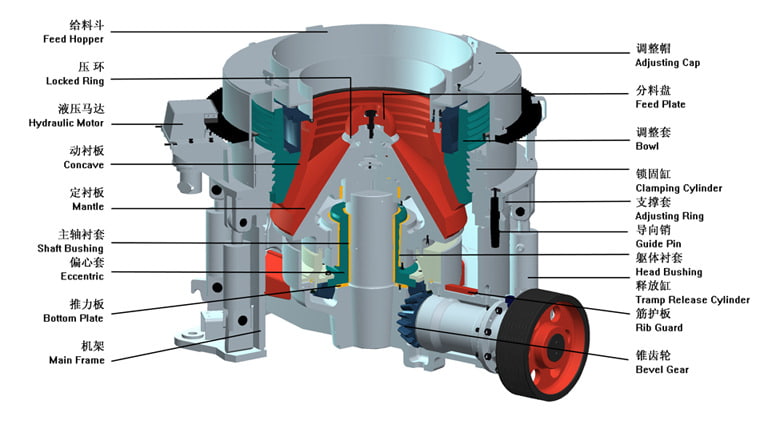

A multi-cylinder hydraulic cone crusher uses multiple independent hydraulic cylinders to provide stronger support, precise control, and enhanced crushing force. Compared with spring cone crushers and single-cylinder models, it offers higher output capacity, better particle shape, and improved stability.

Working Principle Explained

The machine operates based on the compression crushing principle. Here’s how the process works step by step:

1. Feeding the Material

Raw material enters the crushing chamber through the top feed opening. A wear-resistant feeding plate helps distribute material evenly, reducing wear and ensuring stable crushing.

2. Eccentric Rotation Produces Crushing Force

The heart of the machine is the eccentric bushing. When the main motor drives the eccentric assembly, the mantle begins to rotate in a non-concentric motion.

This creates a powerful crushing force between the mantle and concave (fixed liner).

3. Multi-Cylinder Hydraulic Support System

Multiple hydraulic cylinders surround the main shaft. Their functions include:

Adjusting the discharge opening automatically

Providing overload protection

Stabilizing the crushing pressure

Maintaining consistent output size

If uncrushable objects (such as iron pieces) enter the chamber, the hydraulic system immediately releases pressure to prevent damage, then automatically resets.

4. Continuous Layer Crushing

Inside the chamber, material is crushed through repeated compression and friction.

The crusher uses a laminated crushing principle, which means:

Material is crushed between particles

Final products are more uniform and cubical

Wear on liners is reduced

Crushing efficiency increases

5. Automatic Discharge Control

Crushed material exits through the discharge opening at the bottom.

With automatic closed-side setting (CSS) adjustment, operators can precisely control the final particle size without manual intervention.

Key Features That Improve Performance

A multi-cylinder hydraulic cone crusher is preferred for its technical advantages:

✔ High Crushing Efficiency

Multiple cylinders generate stronger and more stable crushing pressure.

✔ Excellent Particle Shape

Laminated crushing ensures uniform, cubic finished aggregates.

✔ Full Automation and Easy Control

Hydraulic adjustment + PLC control system improves reliability and operation safety.

✔ Strong Overload Protection

Independent hydraulic cylinders prevent mechanical damage and reduce downtime.

✔ Large Capacity and High Output

Optimized chamber design increases throughput for both secondary and tertiary crushing.

✔ Low Operating and Maintenance Costs

Hydraulic systems reduce manual adjustments and extend wear part life.

Common Applications

Multi-cylinder hydraulic cone crushers are widely used in:

Hard stone crushing (granite, basalt, river stone)

Mining and ore processing (copper ore, iron ore, gold ore)

Sand and aggregate production lines

Construction materials and railway projects

Their ability to handle high hardness materials makes them ideal for heavy-duty environments.

Conclusion

A multi-cylinder hydraulic cone crusher works through coordinated hydraulic control, eccentric rotation, and laminated crushing. Its robust design ensures high productivity, precise output size control, and unmatched reliability—making it one of the most efficient crushing machines for modern mining and aggregate industries.