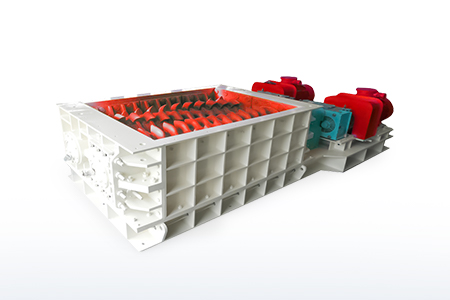

The double roll crusher is a versatile medium-to-fine crushing equipment widely used in mining, aggregate production, coal processing, and recycling industries. Characterized by its simple structure, low noise, and uniform product granularity, it is ideal for crushing brittle, low-abrasive materials such as limestone, coal, gypsum, and salt. Understanding double roll crusher specification is critical for selecting the right model, optimizing production efficiency, and ensuring consistent product quality. This comprehensive guide breaks down the core technical parameters, classification by specifications, and practical selection tips for double roll crushers.

Core Categories of Double Roll Crusher Specification

1. Structural Specifications of Double Roll Crusher

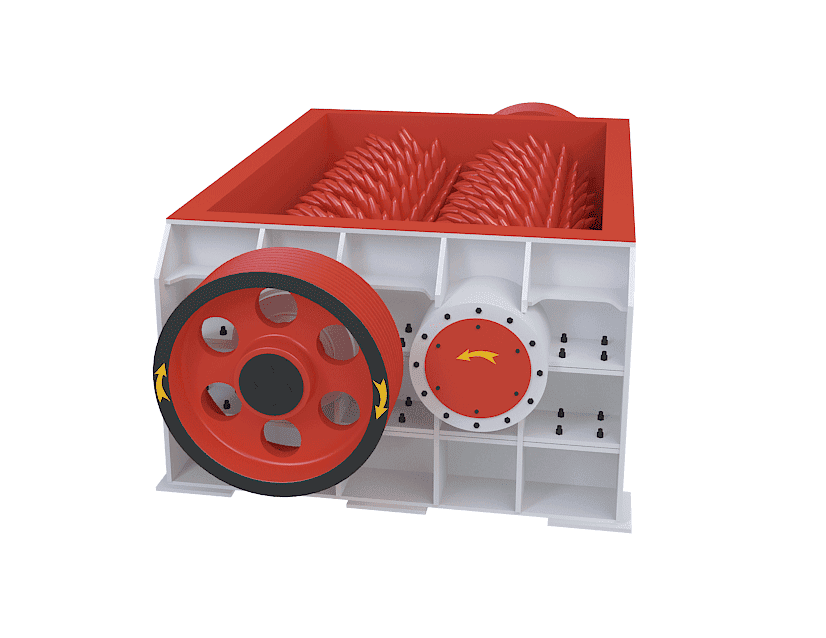

Roll Diameter & Length: The most fundamental structural specification, usually expressed as D×L (e.g., 400×600mm, 800×1000mm). Larger roll diameter increases crushing force, suitable for coarse-to-medium crushing; longer roll length boosts processing capacity. For example, a 600×800mm double roll crusher handles larger feed sizes than a 400×600mm model, while a 800×1200mm model delivers higher hourly output due to its extended roll length.

Roll Material & Surface Type: A key specification related to wear resistance. Common roll materials include manganese steel (for high-abrasive materials), alloy steel (for hard materials), and rubber (for sticky materials). Surface types are divided into smooth rolls (for uniform particle size) and toothed rolls (for stronger crushing force, suitable for coal and shale).

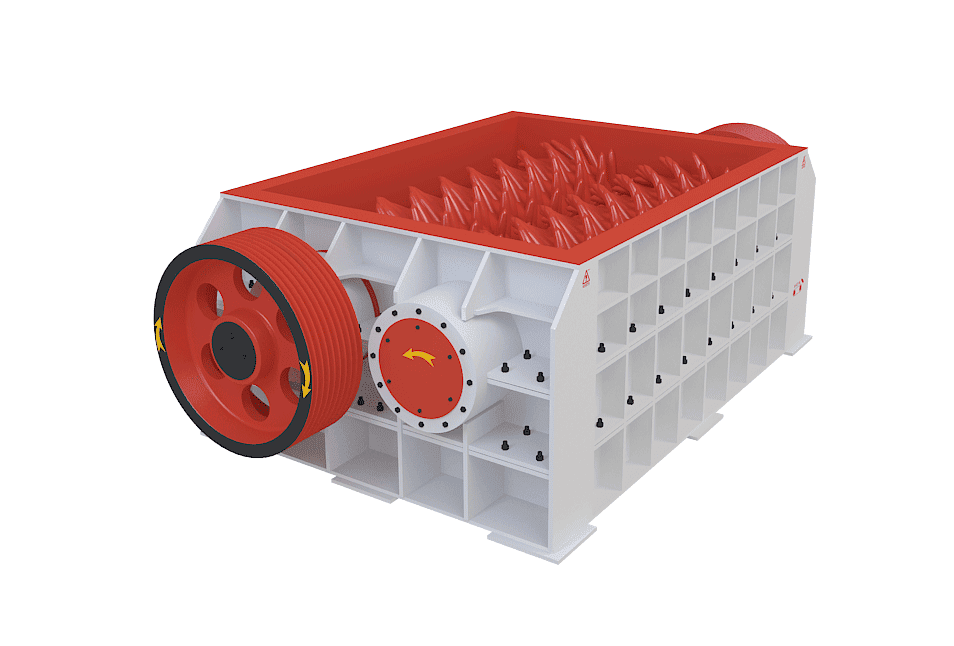

Frame Structure: Specifications include integral cast steel frame (for heavy-duty operation) and welded steel frame (cost-effective, for light-to-medium duty). The frame weight specification also affects installation stability—heavier frames reduce vibration during high-capacity operation.

Adjustment Mechanism: Specifies the gap adjustment method, including manual adjustment (for small-scale production) and hydraulic adjustment (for large-scale, automated lines). The adjustment range (usually 5–50mm) determines the minimum discharge particle size.

2. Performance Specifications of Double Roll Crusher

Processing Capacity: Measured in tons per hour (t/h), ranging from 5t/h for small models to 500t/h for large industrial models. Capacity is determined by roll size, rotation speed, and material characteristics. For example, a 500×750mm double roll crusher has a capacity of 20–50t/h for limestone, while a 1000×1200mm model reaches 150–300t/h.

Feed Size & Discharge Size Range: Feed size specification refers to the maximum particle size the equipment can handle (usually ≤150mm for medium models, ≤300mm for heavy-duty models). Discharge size is adjustable within the gap range—for example, a model with a 5–40mm adjustment range can produce 5–10mm fine aggregates or 20–40mm medium aggregates.

Motor Power: Ranges from 7.5kW for small models to 200kW for large models. Higher motor power supports higher rotation speeds and crushing force, suitable for hard materials (e.g., limestone with compressive strength ≤200MPa requires at least 37kW motor power).

Roll Rotation Speed: Typically 50–300r/min. Lower speeds (50–100r/min) produce uniform particle sizes and reduce over-crushing; higher speeds (150–300r/min) improve processing capacity, ideal for bulk material crushing.

3. Material Compatibility Specifications of Double Roll Crusher

Maximum Material Compressive Strength: Most double roll crushers are suitable for materials with compressive strength ≤250MPa, such as limestone, coal, and gypsum. Models with high-hardness rolls can handle materials up to 300MPa, but are not recommended for hard, abrasive materials like granite or basalt.

Material Moisture Content: The optimal moisture content specification is ≤10%. Materials with moisture content exceeding 15% are prone to sticking to the rolls, causing blockages and reducing output. For high-moisture materials, choose models with anti-stick roll surfaces or heating functions.

Material Impurity Content: Specifications limit the content of hard impurities (e.g., metal blocks) to ≤1%. Excessive impurities can cause roll surface damage or shaft bending, requiring additional magnetic separation equipment for impurity removal.

Classification of Double Roll Crushers by Specification

- By Roll Size Specification

Small-Scale Double Roll Crusher (D≤500mm, L≤800mm): Capacity 5–50t/h, suitable for small workshops, laboratory testing, or auxiliary crushing in production lines.

Medium-Scale Double Roll Crusher (500mm<D≤1000mm, 800mm<L≤1500mm): Capacity 50–200t/h, ideal for aggregate production and coal processing in medium-sized mines.

Large-Scale Double Roll Crusher (D>1000mm, L>1500mm): Capacity 200–500t/h, designed for large-scale mining and infrastructure projects requiring high-volume, continuous crushing.

- By Adjustment Mechanism Specification

Manual Adjustment Double Roll Crusher: Low cost, suitable for small-scale production with infrequent particle size changes.

Hydraulic Adjustment Double Roll Crusher: Automatically adjusts roll gap, overload protection function, ideal for large-scale, automated production lines.

Key Tips for Selecting Double Roll Crushers Based on Specifications

Match Roll Size & Capacity to Production Demand: Calculate the required hourly output and choose a model with 10–20% higher capacity to avoid production bottlenecks. For example, a 100t/h aggregate line requires a medium-scale double roll crusher with 120t/h capacity.

Select Roll Material Based on Material Abrasiveness: Use manganese steel rolls for abrasive materials (e.g., limestone) and rubber rolls for sticky materials (e.g., wet coal).

Adjust Rotation Speed According to Particle Size Requirements: Choose low-speed models for fine, uniform products and high-speed models for bulk crushing.

Check Installation Space Compatibility: Confirm the equipment’s overall dimensions and weight specifications match the production site’s space and hoisting capacity.

Common Misunderstandings About Double Roll Crusher Specification

Blindly Pursuing Large Roll Size: Oversized rolls increase investment and energy consumption, with no significant output improvement for small-scale production.

Ignoring Moisture Content Limits: Using high-moisture materials beyond the specification causes roll blockages and equipment downtime.

Neglecting Adjustment Mechanism Type: Manual adjustment models are not suitable for automated lines, leading to inefficient particle size changes.