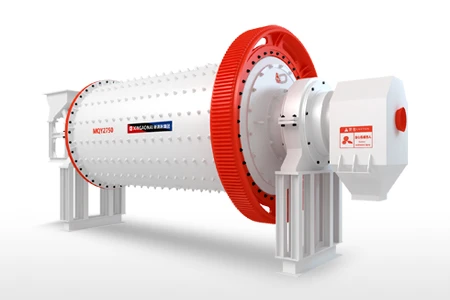

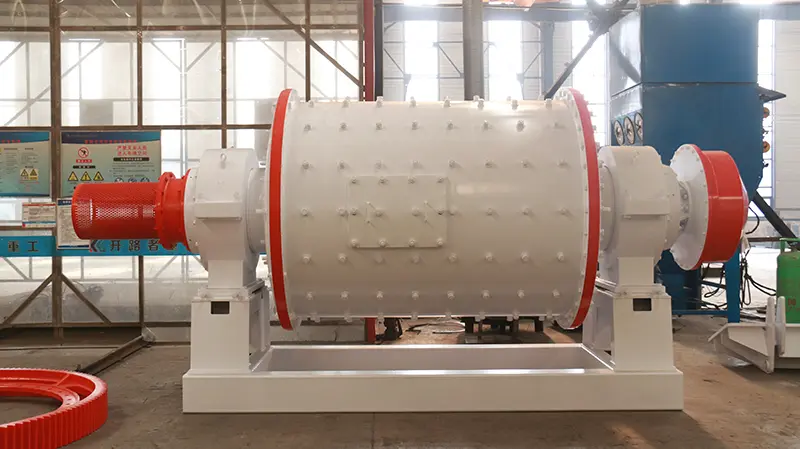

A ball mill liner is an essential protective and functional component of industrial ball mills, widely used in mining, cement, metallurgy, and chemical industries for grinding and processing bulk materials such as ores, minerals, and aggregates. As the inner lining of the ball mill’s cylinder, the ball mill liner serves multiple critical roles: protecting the mill shell from wear and impact, guiding the movement of grinding media (balls), and optimizing the grinding efficiency of the entire equipment. Choosing the right ball mill liner—including the correct type, material, and design—is vital to extending the service life of the ball mill, reducing maintenance costs, and ensuring consistent production output.

Unlike other ball mill components, the ball mill liner is directly exposed to the harsh working environment of the mill cylinder: constant impact from grinding balls, abrasion from raw materials, and high temperatures generated during the grinding process. This makes the quality and durability of the ball mill liner a key factor in the overall performance and operational efficiency of the ball mill. Below is a comprehensive guide to ball mill liner, covering its types, materials, functions, installation, and maintenance.

Core Functions of a Ball Mill Liner

The ball mill liner is not just a protective layer—it plays a proactive role in optimizing the ball mill’s grinding process. Its core functions are interconnected, ensuring the mill operates efficiently and reliably:

1. Protecting the Ball Mill Cylinder

The primary function of a ball mill liner is to shield the mill’s steel cylinder from direct impact and abrasion. During ball mill operation, grinding balls and raw materials collide with high force against the inner wall of the cylinder; without a ball mill liner, the cylinder would quickly wear down, develop cracks, and require costly repairs or replacement. The liner absorbs the impact energy and resists abrasive wear, extending the service life of the ball mill’s main structure.

2. Guiding Grinding Media Movement

Ball mill liners are designed with specific profiles (shapes) to control the movement of grinding balls inside the cylinder. The liner’s profile determines whether the balls cascade (fall gently) or cataract (fall forcefully), which directly impacts grinding efficiency. A well-designed ball mill liner ensures the grinding balls move in a way that maximizes contact with raw materials, breaking them down into the desired particle size quickly and uniformly.

3. Optimizing Grinding Efficiency

By controlling the trajectory of grinding balls and reducing energy loss, the ball mill liner improves the overall grinding efficiency of the ball mill. The liner’s surface texture and profile minimize slipping of the grinding balls, ensuring more effective impact and friction between the balls and the raw materials. This reduces the time required for grinding, lowers energy consumption, and increases the mill’s production capacity.

4. Preventing Material Contamination

In applications requiring high-purity final products (such as pharmaceutical, food, or high-grade mineral processing), the ball mill liner prevents contamination of the raw materials. High-quality liners made from non-toxic, wear-resistant materials do not shed particles into the grinding chamber, ensuring the purity and quality of the processed materials.

Common Types of Ball Mill Liners

Ball mill liners are available in various types, each designed for specific grinding applications, mill sizes, and material characteristics. The choice of ball mill liner type depends on factors such as the type of raw material, grinding media size, and desired production output. The most common types include:

1. Grid Ball Mill Liners

Grid ball mill liners are characterized by their grid-like structure, which is designed to enhance the cascading movement of grinding balls. They are typically used in primary grinding applications, where large, hard raw materials need to be broken down into smaller particles. The grid design of this ball mill liner helps to prevent the grinding balls from clustering and ensures uniform grinding of the raw materials. Grid liners are commonly used in mining and mineral processing for grinding ores such as gold, copper, and iron.

2. Wave Ball Mill Liners

Wave ball mill liners feature a wavy profile that creates a more intense cataracting movement of the grinding balls. This type of ball mill liner is ideal for secondary grinding applications, where the raw materials have already been crushed to a smaller size and require finer grinding. The wave profile increases the impact force of the grinding balls, improving the efficiency of fine grinding and reducing the particle size of the final product. Wave liners are widely used in cement plants and aggregate processing facilities.

3. Segment Ball Mill Liners

Segment ball mill liners are made up of individual segments that are bolted to the inner wall of the mill cylinder. This modular design makes installation and replacement of the ball mill liner easier and more cost-effective—instead of replacing the entire liner, only the worn segments need to be changed. Segment liners are available in various profiles (grid, wave, or flat) and can be customized to fit different ball mill sizes and applications. They are the most commonly used type of ball mill liner in industrial settings.

4. Rubber Ball Mill Liners

Rubber ball mill liners are made from high-quality natural or synthetic rubber, offering excellent wear resistance, impact absorption, and corrosion resistance. Unlike steel liners, rubber liners are lightweight, reduce noise during ball mill operation, and minimize wear on the grinding balls. They are ideal for grinding abrasive, but not extremely hard, materials such as limestone, coal, and fertilizers. Rubber ball mill liners are also used in applications where material contamination must be avoided.

5. Steel Ball Mill Liners

Steel ball mill liners are made from high-strength steel alloys (such as manganese steel, chromium steel, or alloy steel) and are designed for heavy-duty grinding applications. They offer superior impact resistance and durability, making them suitable for grinding hard, abrasive materials such as granite, basalt, and iron ore. Steel liners are available in various thicknesses and profiles, and their service life is longer than rubber liners in harsh working environments. However, they are heavier and generate more noise during operation.

Key Materials for Ball Mill Liners

The material of a ball mill liner directly impacts its durability, wear resistance, and performance. The choice of material depends on the type of raw material being ground, the grinding media used, and the operational conditions of the ball mill. The most common materials for ball mill liners include:

1. Manganese Steel (Hadfield Steel)

Manganese steel is the most widely used material for ball mill liners, thanks to its excellent impact resistance and work-hardening properties. When exposed to impact and abrasion, the surface of manganese steel hardens, while the inner core remains tough and ductile. This makes manganese steel ball mill liners ideal for grinding hard, abrasive materials and heavy-duty applications. They are commonly used in mining, metallurgy, and cement industries.

2. Rubber

Rubber (natural or synthetic) is a popular material for ball mill liners in applications requiring low noise, low wear on grinding balls, and resistance to corrosion. Rubber liners are lightweight, easy to install, and offer good abrasion resistance for non-extremely hard materials. They are also non-toxic, making them suitable for food and pharmaceutical processing. However, rubber liners have a shorter service life than steel liners in harsh, high-impact environments.

3. Alloy Steel

Alloy steel ball mill liners are made by adding alloying elements (such as chromium, nickel, or molybdenum) to steel, improving its wear resistance, strength, and corrosion resistance. They are used in applications where the ball mill operates under high pressure, high temperature, or corrosive conditions. Alloy steel liners have a longer service life than manganese steel liners but are more expensive.

4. Polyurethane

Polyurethane ball mill liners are lightweight, flexible, and offer excellent abrasion resistance and chemical resistance. They are ideal for grinding materials that are prone to sticking to the liner, as polyurethane has a non-stick surface. Polyurethane liners also reduce noise and wear on grinding balls, but they are not suitable for high-impact applications, as they are less impact-resistant than steel or rubber.

Installation and Replacement Tips for Ball Mill Liners

Proper installation and timely replacement of ball mill liners are critical to ensuring the ball mill’s performance and safety. Improper installation can lead to liner damage, reduced grinding efficiency, and even equipment failure. Follow these tips for ball mill liner installation and replacement:

1. Pre-Installation Preparation

Before installing a new ball mill liner, clean the inner wall of the mill cylinder thoroughly to remove any debris, rust, or old liner fragments. Inspect the cylinder for cracks, deformation, or damage—repair any issues before installing the new liner. Check the bolts, nuts, and gaskets used to secure the liner, ensuring they are in good condition and compatible with the liner type.

2. Correct Liner Alignment

When installing segment ball mill liners, ensure each segment is aligned correctly with the adjacent segments, with no gaps or overlaps. Misaligned liners can cause uneven wear, increased vibration, and reduced grinding efficiency. Use a level and measuring tools to ensure the liner is installed evenly and securely.

3. Proper Bolt Tightening

Tighten the bolts used to secure the ball mill liner to the recommended torque, following the manufacturer’s guidelines. Over-tightening can damage the liner or bolts, while under-tightening can cause the liner to shift during operation, leading to wear and damage. Recheck the bolt tightness after the first few hours of operation, as vibration can loosen the bolts.

4. Timely Replacement

Monitor the condition of the ball mill liner regularly for signs of wear, damage, or thinning. Common signs that a ball mill liner needs replacement include excessive wear on the liner surface, cracks, holes, or reduced grinding efficiency. Replace the liner before it becomes too worn, as a damaged liner can cause damage to the mill cylinder and other components, leading to costly downtime.

Maintenance Best Practices for Ball Mill Liners

Proper maintenance of ball mill liners can extend their service life, reduce replacement costs, and ensure the ball mill operates at peak efficiency. Follow these maintenance best practices:

1. Regular Inspection

Conduct daily visual inspections of the ball mill liner to check for signs of wear, damage, or loose bolts. Conduct a detailed weekly inspection to measure the liner thickness and check for any hidden damage. Keep a record of inspections to track the liner’s wear rate and plan for replacement.

2. Keep the Liner Clean

Regularly clean the ball mill liner to remove any material buildup, which can cause uneven wear and reduce grinding efficiency. Use a brush, air compressor, or low-pressure water to clean the liner surface—avoid using high-pressure water, which can damage the liner or the mill cylinder.

3. Optimize Ball Mill Operation

Operate the ball mill within the recommended parameters (speed, load, and feed rate) to reduce unnecessary wear on the ball mill liner. Avoid overloading the mill, as this increases the impact force on the liner and accelerates wear. Ensure the raw materials are properly crushed before feeding into the mill, reducing the impact on the liner.

4. Choose High-Quality Liners

Invest in high-quality ball mill liners from reputable manufacturers. High-quality liners are made from durable materials, designed to withstand harsh working conditions, and offer better performance and longer service life than low-quality liners. While they may have a higher initial cost, they reduce long-term maintenance and replacement costs.

Conclusion

A ball mill liner is a critical component that impacts the performance, durability, and efficiency of industrial ball mills. Its role in protecting the mill cylinder, guiding grinding media, and optimizing the grinding process cannot be overstated. By understanding the different types, materials, functions, and maintenance requirements of ball mill liners, you can choose the right liner for your application, extend its service life, and ensure your ball mill operates reliably and efficiently.

Whether you’re in the mining, cement, or chemical industry, investing in a high-quality ball mill liner and following proper installation and maintenance practices is essential to reducing operational costs, minimizing downtime, and maximizing production output. The ball mill liner may be a small component, but it is a key factor in the success of your grinding operations.