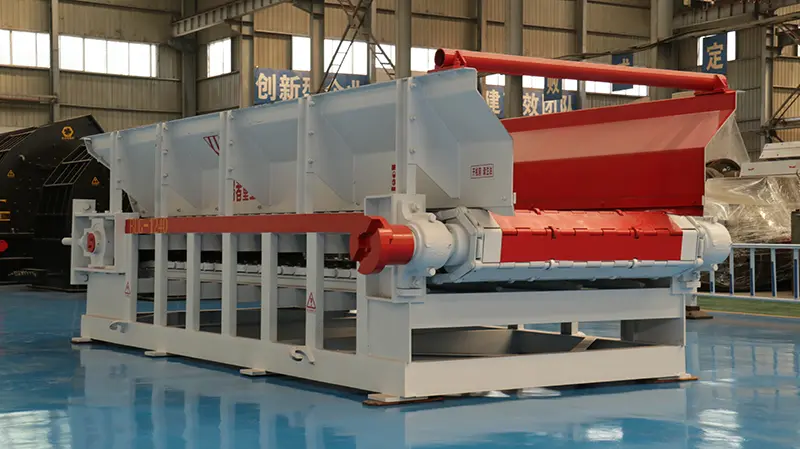

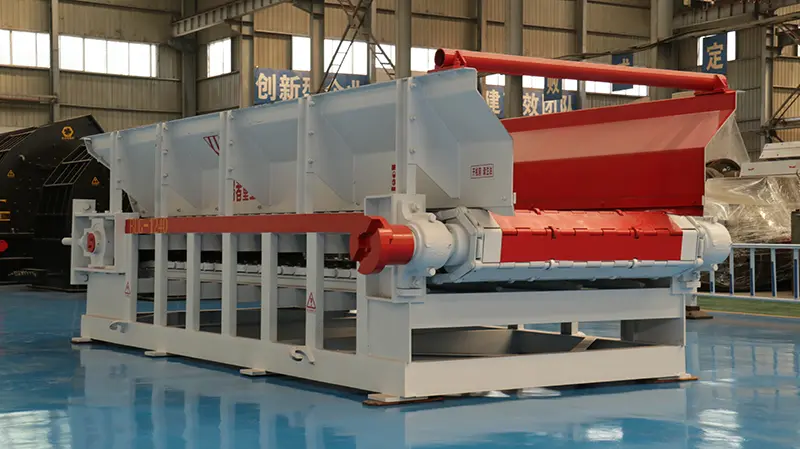

An apron feeder chain is a critical structural and functional component of industrial apron feeders, the heavy-duty material handling equipment used to convey bulk, abrasive, and high-weight solids across mining, construction, and aggregate processing operations. As the backbone of the apron feeder’s conveying system, the

apron feeder chain connects the steel or rubber pans (aprons) that hold and transport materials, ensuring smooth, continuous, and stable movement even under extreme load conditions and harsh working environments. Unlike standard conveyor chains, an apron feeder chain is engineered with reinforced links, heavy-duty pins, and wear-resistant materials to withstand impact, friction, and corrosion—making it an irreplaceable part for maintaining the efficiency and reliability of apron feeders in high-capacity industrial workflows.

Core Design Features of an Apron Feeder Chain

The performance and longevity of an apron feeder chain depend on its precision engineering and robust design, tailored to meet the demands of heavy-duty material conveying. Every feature of the apron feeder chain is optimized for durability, load-bearing capacity, and compatibility with apron feeder systems:

1. Reinforced Link Construction

An apron feeder chain features thick, high-strength steel links—typically made from carbon steel, alloy steel, or manganese steel—for superior tensile strength and impact resistance. The links are forged or stamped to create a rigid structure that prevents bending or deformation under the weight of heavy bulk materials like ore, rock, and concrete aggregates.

2. Heavy-Duty Pins and Bushings

The connecting pins and bushings of an apron feeder chain are manufactured from heat-treated steel to reduce wear and friction during rotation. Precision-machined to ensure a tight fit, these components minimize play between links, preventing misalignment and ensuring smooth chain movement along the apron feeder’s sprockets and track.

3. Wear-Resistant Coatings

Most industrial apron feeder chains are coated with anti-corrosive and anti-wear finishes such as galvanization, powder coating, or hard chrome plating. These coatings protect the chain from rust, chemical corrosion, and abrasive wear caused by contact with sharp or gritty materials, extending its service life in wet, dusty, or acidic industrial environments.

4. Customizable Pitch and Width

The pitch (distance between chain links) and width of an apron feeder chain are customizable to match the specific model and capacity of the apron feeder. A larger pitch is used for heavy-load applications, while a narrower width suits compact apron feeders, ensuring perfect compatibility with the feeder’s pans and drive system.

5. Sprocket Compatibility

An apron feeder chain is designed to mesh seamlessly with the apron feeder’s drive and idler sprockets. The chain’s tooth profile is precision-engineered to prevent slipping or jumping, ensuring consistent power transmission and smooth conveying of materials at a controlled speed.

Key Functions of an Apron Feeder Chain in Material Handling

The apron feeder chain serves three primary, non-negotiable functions in the operation of an apron feeder, all critical to efficient and safe heavy-duty material conveying:

Pan Connection & Support: The apron feeder chain securely fastens the individual conveying pans (aprons) together, creating a continuous, rigid conveying surface that can hold and transport large volumes of bulk materials without sagging or separation.

Power Transmission: It transfers rotational power from the apron feeder’s drive sprocket to the entire conveying system, driving the movement of the pans along the feeder’s track at a steady, adjustable speed—ensuring uniform material feeding to downstream equipment like crushers, screens, and dryers.

Load Distribution: The apron feeder chain distributes the weight of the conveyed materials evenly across the feeder’s track and support structure, reducing stress on individual components and preventing premature failure of the apron feeder’s frame or drive system.

Critical Maintenance Best Practices for Apron Feeder Chain

Proper maintenance of an apron feeder chain is essential to avoid unplanned downtime, reduce replacement costs, and ensure the long-term reliability of the apron feeder. Neglecting chain maintenance can lead to excessive wear, misalignment, or even chain breakage—catastrophic issues for industrial material handling workflows. Follow these industry-proven best practices for apron feeder chain care:

1. Regular Lubrication

Lubricate the apron feeder chain’s pins, bushings, and link joints with a high-quality, heavy-duty lubricant recommended by the manufacturer. Lubrication reduces friction and wear, prevents rust, and ensures smooth chain movement. For dusty or wet environments, use a waterproof, anti-contamination lubricant to avoid buildup of grit or moisture in the chain’s moving parts.

2. Routine Inspection

Conduct daily visual inspections of the apron feeder chain to check for signs of wear, damage, or misalignment. Look for stretched links, worn pins or bushings, cracked or bent links, and loose connections to the pans. Conduct a weekly detailed inspection to check chain tension and sprocket meshing—misaligned sprockets cause uneven wear on the apron feeder chain and must be realigned immediately.

3. Tension Adjustment

Maintain proper tension in the apron feeder chain at all times. Too much tension causes excessive stress on the chain and drive system, while insufficient tension leads to slipping, jumping, or chain derailment. Adjust the chain’s tension using the apron feeder’s idler sprocket tensioner, following the manufacturer’s specified tension levels for your chain model and application.

4. Cleaning

Keep the apron feeder chain free of material buildup, dust, and debris. Use a brush, air compressor, or low-pressure water to clean the chain regularly—buildup can cause friction, corrosion, and misalignment, reducing the chain’s performance and lifespan. Avoid using high-pressure water, which can wash away lubricant and damage bearing seals.

5. Wear Part Monitoring

Track the wear of the

apron feeder chain’s critical components (pins, bushings, links) using measurement tools. Replace worn components before they cause complete chain failure—most manufacturers provide a maximum wear limit for each part, and adhering to this prevents costly repairs and unplanned downtime.

Apron Feeder Chain Replacement: Key Considerations

Even with proper maintenance, an apron feeder chain will eventually reach the end of its service life and require replacement. When sourcing a replacement apron feeder chain, keep these critical factors in mind to ensure optimal performance and compatibility:

1. Exact Compatibility

Always select an apron feeder chain that is a direct match for your apron feeder’s make, model, and capacity. Ill-fitting chains will cause misalignment, excessive wear, and poor performance, and may even damage the feeder’s pans, sprockets, or drive system. Work with reputable suppliers that offer OEM or OEM-equivalent apron feeder chains for your specific equipment.

2. Material Quality

Choose an apron feeder chain made from high-quality, wear-resistant materials that match your application. For abrasive materials like rock and ore, select a manganese steel chain for superior impact resistance; for corrosive environments, opt for a stainless steel or galvanized chain to prevent rust and corrosion.

3. Manufacturer Reputation

Source your apron feeder chain from a trusted industrial component manufacturer with a proven track record of producing durable, high-performance conveyor and feeder chains. Reputable manufacturers offer quality warranties, technical support, and installation guidance—ensuring your replacement chain is installed correctly and performs as expected.

4. Application Specifics

Consider the unique demands of your material handling application when selecting a replacement apron feeder chain. If you convey extremely heavy loads or sharp, abrasive materials, choose a heavy-duty, reinforced chain with extra-thick links and hardened pins. For high-temperature environments, select a heat-resistant chain that can withstand extreme temperatures without warping or weakening.

Industrial Applications of Apron Feeder Chain

An apron feeder chain is used in every industry where apron feeders are deployed for heavy-duty bulk material handling, as it is the core component that enables the feeder’s operation. The most common industrial applications for apron feeder chain include:

1. Mining & Mineral Processing

In surface and underground mining, apron feeder chains are used in apron feeders that convey raw ore, coal, and minerals from stockpiles to crushers, grinders, and processing plants. The heavy-duty design of the mining-grade apron feeder chain withstands the impact of large, sharp rocks and the harsh conditions of mining sites.

2. Construction & Demolition

Construction and demolition projects use apron feeder chains in apron feeders that convey concrete, brick, stone, and demolition waste to crushers and recycling equipment. The chain’s wear resistance and load-bearing capacity make it ideal for handling the heavy, abrasive materials common in construction workflows.

3. Aggregate & Quarrying

Quarries and aggregate plants rely on apron feeder chains to convey limestone, granite, sand, and gravel from extraction sites to screening and crushing equipment. The chain’s precise speed control ensures uniform feeding, optimizing the efficiency of aggregate production lines.

4. Cement & Building Materials

Cement plants and building material manufacturers use apron feeder chains in apron feeders that convey clinker, limestone, and raw materials to kilns, grinders, and mixers. The anti-corrosive coatings on these chains protect against the acidic and dusty environments of cement production.

5. Waste Management & Recycling

Waste management facilities use apron feeder chains in heavy-duty apron feeders that convey municipal solid waste, industrial waste, and recyclable materials to shredders and separators. The chain’s robust design handles the mixed, irregular materials common in recycling workflows without jamming or breaking.

Conclusion

An apron feeder chain is the unsung hero of heavy-duty industrial material handling, serving as the core component that enables

apron feeders to convey bulk, abrasive, and heavy materials across mining, construction, and aggregate operations. Its reinforced design, wear-resistant materials, and precision engineering make it capable of withstanding the harshest industrial environments and heaviest load conditions—while proper maintenance and careful replacement ensure its long-term reliability and performance. For any industrial operation that relies on apron feeders for continuous material feeding, understanding the design, function, and care of the apron feeder chain is critical to minimizing downtime, reducing operational costs, and optimizing the efficiency of material handling workflows. Investing in a high-quality apron feeder chain and following strict maintenance best practices is not just a cost-saving measure—it is a necessity for keeping industrial production lines running smoothly and safely.