In the mining, construction, and aggregate processing industries, gyratory crushers stand out as indispensable heavy-duty equipment for primary crushing. Their ability to handle large, hard raw materials—such as granite, basalt, and iron ore—with high efficiency makes them a cornerstone of many production lines. But for those new to the field or seeking to deepen their understanding, a fundamental question remains: how does a gyratory crusher work? This article breaks down its core components, operational principles, and workflow to provide a clear, comprehensive answer.

Core Components of a Gyratory Crusher: The Building Blocks of Crushing

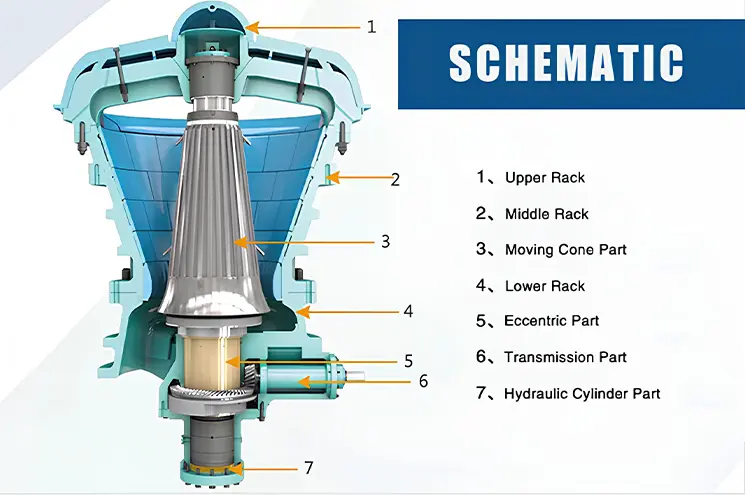

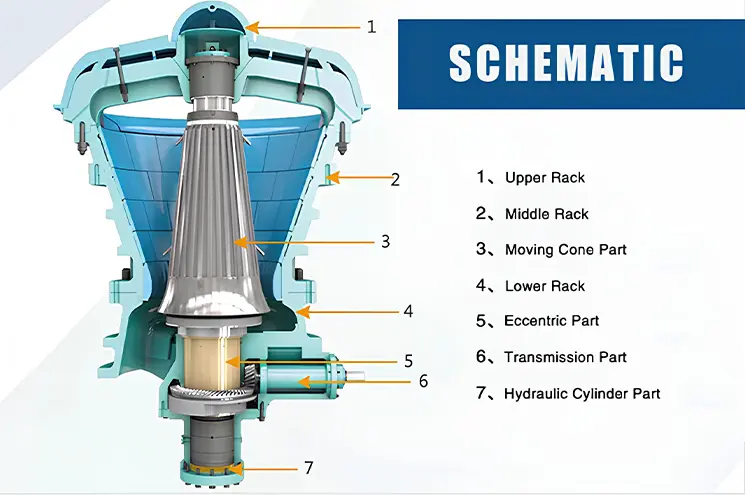

Before delving into the working process, it is essential to understand the key components that enable a gyratory crusher to function. Each part plays a unique role in converting mechanical energy into the crushing force needed to reduce material size. The main components include:

Eccentric Shaft: The "power core" of the crusher. Driven by a motor and transmission system, the eccentric shaft rotates to create the reciprocating and rotational motion required for crushing.

Crushing Cone (Movable Cone): Attached to the eccentric shaft, the crushing cone is a conical structure with a wear-resistant surface. Its movement—combining rotation and oscillation—is the direct driver of the crushing action.

Concave (Fixed Cone): A stationary conical component that surrounds the crushing cone, forming a crushing cavity (also called a working cavity) between the two. The inner surface of the concave is also wear-resistant, matching the shape of the crushing cone to ensure uniform crushing.

Feed Hopper & Distributor: The feed hopper guides raw materials into the crusher, while the distributor (located at the top of the crushing cone) ensures even distribution of materials into the crushing cavity, preventing uneven wear and improving crushing efficiency.

Discharge Opening: Located at the bottom of the crushing cavity, the size of the discharge opening can be adjusted to control the particle size of the crushed product, meeting different production requirements.

Lubrication System: Given the heavy load and high friction during operation, a reliable lubrication system (usually oil lubrication) cools and lubricates moving parts, extending the service life of the crusher.

The Working Mechanism: How a Gyratory Crusher Crushes Materials Step by Step

The core principle of a

gyratory crusher relies on the relative motion between the movable crushing cone and the fixed concave to generate squeezing, bending, and impact forces, thereby breaking down raw materials. The entire working process can be divided into four key stages, which clearly answer the question "how does a gyratory crusher work":

1. Material Feeding & Distribution

Large raw materials (with particle sizes ranging from several hundred millimeters to over one meter, depending on the crusher model) are first transported to the feed hopper by conveyor belts or other feeding equipment. The material then flows into the distributor at the top of the crushing cone. The rotating distributor evenly spreads the material into the annular crushing cavity formed by the crushing cone and the concave. This even distribution is critical—it avoids localized overloading of the crushing components, reduces wear, and ensures consistent crushing efficiency.

2. Eccentric Shaft Drives the Crushing Cone’s Motion

When the crusher is started, the motor drives the transmission system (including gears and pulleys), which in turn drives the eccentric shaft to rotate at a certain speed (typically 100–300 rpm). The eccentric shaft is designed with an offset center of rotation, so as it rotates, it causes the crushing cone attached to it to perform a special motion: the cone not only rotates around its own central axis but also oscillates (swings) around the central axis of the crusher. This combined motion makes the gap between the crushing cone and the concave constantly change—narrowing and widening alternately.

3. Crushing: Squeezing & Breaking the Material

As the crushing cone oscillates, the material in the crushing cavity is subjected to repeated squeezing, bending, and shearing forces. When the gap between the crushing cone and the concave narrows, the material is tightly pressed between the two conical surfaces, and the force exceeds the compressive strength of the material, causing it to crack or break into smaller pieces. When the gap widens, the crushed material moves downward under the action of gravity and continues to be crushed by the subsequent narrowing of the gap. This cyclic process ensures that the material is gradually reduced in size as it moves from the upper (wider) part of the crushing cavity to the lower (narrower) part.

4. Discharging of Finished Products

When the material is crushed to a particle size smaller than the width of the discharge opening, it falls out of the crusher through the discharge opening and is transported to the next processing link (such as secondary crushing or screening) by a conveyor belt. The discharge opening can be adjusted according to production needs—rotating the adjustment device (usually a hydraulic or mechanical system) changes the distance between the bottom of the crushing cone and the concave, thereby controlling the fineness of the finished product.

Why Gyratory Crushers Are Preferred: Efficiency Backed by Their Working Principle

The unique working principle of

gyratory crushers gives them distinct advantages over other crushing equipment (such as jaw crushers). First, the continuous crushing process—unlike the intermittent crushing of jaw crushers—ensures higher production capacity, making them suitable for large-scale mining and construction projects. Second, the conical crushing cavity and uniform force application result in a more cubical shape of the finished product, which is highly valued in aggregate applications. Additionally, the wear of key components is relatively uniform due to the even material distribution, reducing maintenance costs and extending the equipment’s service life.

Conclusion: Mastering the Working Principle for Optimal Use

Understanding "how does a gyratory crusher work" is not only essential for equipment operators and maintenance personnel but also for project managers to make rational equipment selection and improve production efficiency. From the rotation of the eccentric shaft to the squeezing of the crushing cone and concave, every link of the gyratory crusher’s working process is a perfect combination of mechanical design and material mechanics. As mining and construction industries continue to develop, gyratory crushers—with their reliable working mechanism and high efficiency—will remain a key force in the crushing field.