The

double roll crusher (also known as a roller crusher) is a widely used crushing equipment in mining, construction, aggregate processing, and chemical industries, especially for handling medium-hard and brittle materials such as coal, limestone, gypsum, and ore. To fully leverage its performance, understanding the double roll crusher working principle is essential for operators, investors, and industry professionals. This article explores the core mechanism, key components, and operational process that define the double roll crusher working principle.

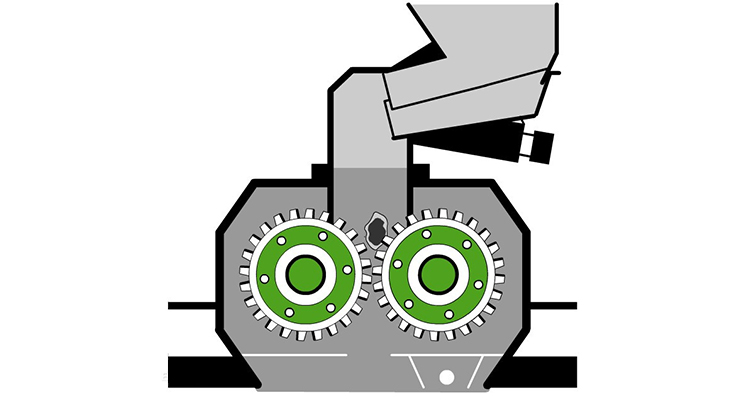

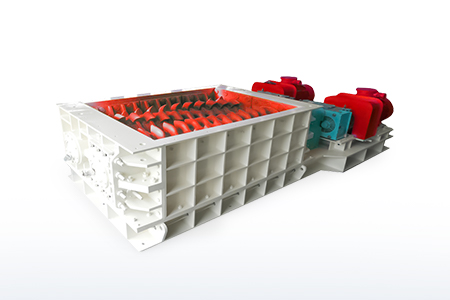

A double roll crusher consists of two parallel, counter-rotating cylindrical rolls (fixed roll and movable roll), a drive system (motor, reducer, coupling), a feeding hopper, a gap adjustment device, and a frame. The rolls are often equipped with wear-resistant liners (such as manganese steel or rubber) to enhance durability and crushing efficiency. The design of the equipment is based on the principle of pressure crushing, which differentiates it from impact crushers or jaw crushers and makes the double roll crusher working principle unique in producing uniform particle sizes.

The double roll crusher working principle revolves around three sequential stages: feeding, compressive crushing, and discharge, all driven by the coordinated operation of key components.

Raw materials are evenly fed into the crushing cavity through the feeding hopper. The hopper is designed with a guide structure to ensure materials flow smoothly between the two parallel rolls without clogging. For optimal performance, the feed size must match the crusher’s specifications—typically no larger than the maximum gap between the rolls at rest. This initial step lays the foundation for the double roll crusher working principle by ensuring consistent material supply to the crushing zone.

This is the core of the

double roll crusher working principle. The two rolls are driven by the motor and reducer to rotate in opposite directions (one fixed, the other adjustable). When materials enter the gap between the rotating rolls, they are subjected to continuous compressive force, shear force, and friction force from the rolls. The pressure applied by the rolls exceeds the compressive strength of the materials, causing them to crack, deform, and break into smaller particles. The wear-resistant liners on the rolls enhance grip and crushing efficiency, preventing materials from slipping during the process. The crushing force can be adjusted via the hydraulic or spring system connected to the movable roll, adapting to different material hardness and crushing requirements.

After being crushed to the desired particle size, the materials pass through the gap between the two rolls and are discharged from the bottom of the crusher. The size of the finished product is directly determined by the gap between the rolls—smaller gaps produce finer particles, while larger gaps yield coarser aggregates. The gap adjustment device allows operators to flexibly control the discharge granularity, which is a key advantage derived from the double roll crusher working principle, making it suitable for various production needs.

To ensure the double roll crusher working principle operates efficiently, several factors must be considered:

Roll Gap Adjustment: Precise gap control directly affects product size and crushing efficiency.

Roll Rotation Speed: Optimal speed balances crushing force and throughput—excessively high speed may cause material slippage, while low speed reduces production capacity.

Material Properties: The double roll crusher working principle performs best with medium-hard, brittle materials; wet or sticky materials may cause clogging and affect performance.

Liner Wear: Regular replacement of worn liners maintains crushing force and prevents uneven particle sizes.

The

double roll crusher working principle is defined by its simple yet efficient compressive crushing mechanism, relying on two counter-rotating rolls to break materials into uniform particles. Its advantages of stable operation, adjustable discharge granularity, and low energy consumption make it a preferred choice for many industries. By mastering the double roll crusher working principle and optimizing key operational factors, users can maximize production efficiency and product quality.