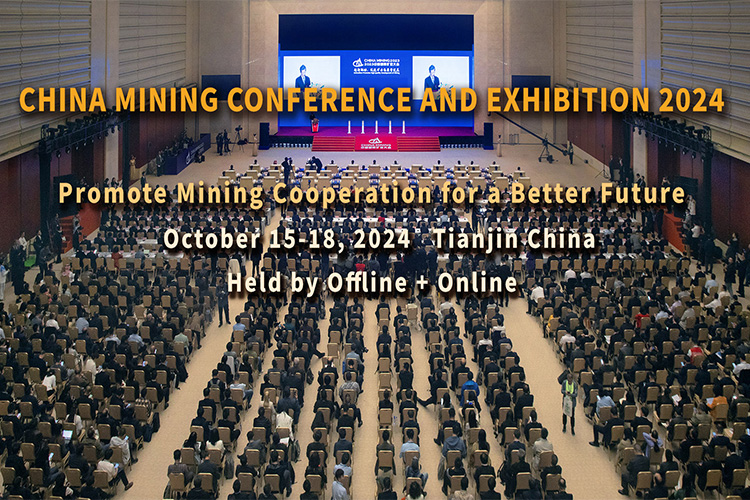

The 2024 (26th) China International Mining Conference, guided by the Ministry of Natural Resources of China and the Tianjin Municipal People's Government, sponsored by the China Mining Federation and hosted by Tianjin Mining Expo International Convention and Exhibition Co., Ltd., will be held from October 15 to 18, 2024 Held at Tianjin Meijiang Convention and Exhibition Center.

With the theme of "Jointly Promoting Mining Cooperation and Creating a Better Future", the conference includes an opening ceremony, bilateral talks with main leaders, theme forums, high-level forums, special forums and promotion seminars, as well as technical equipment exhibitions, etc. It is expected that thousands of mining elites and hundreds of exhibiting companies from all over the world will gather together to explore new opportunities for mining development. At the same time, the conference added a jewelry and jade exhibition area for the first time to achieve the effect of displaying the entire mining industry chain.

Xingaonai Group will comprehensively display the group's latest achievements in the research and development of mining crushing equipment through a carefully designed exhibition area. Displaying a series of intelligent mining machinery and equipment, including high-efficiency and energy-saving crushing equipment, mineral processing equipment, etc., these products adopt the latest automation control technology and energy-saving design, which can significantly improve the efficiency of mining operations and reduce energy consumption. Xingaonai Group specializes in the R&D and manufacturing of mining crushing equipment. Its products cover various types of crushers, screens, etc., which can meet mining enterprises of different sizes and production needs.

Xingaonai Group has a strong independent R&D team and a complete R&D system, which can provide customized solutions according to customer needs. At the exhibition site, we will demonstrate our technical strength and R&D results through videos, models and other forms. We will share our successful cases in the international market in recent years to demonstrate our broad space and deep strength in cooperation with global mining companies.

At the 2024 China International Mining Conference, Xingaonai Group looks forward to working with you hand in hand to jointly explore new opportunities, new challenges and new futures in the mining industry!