The

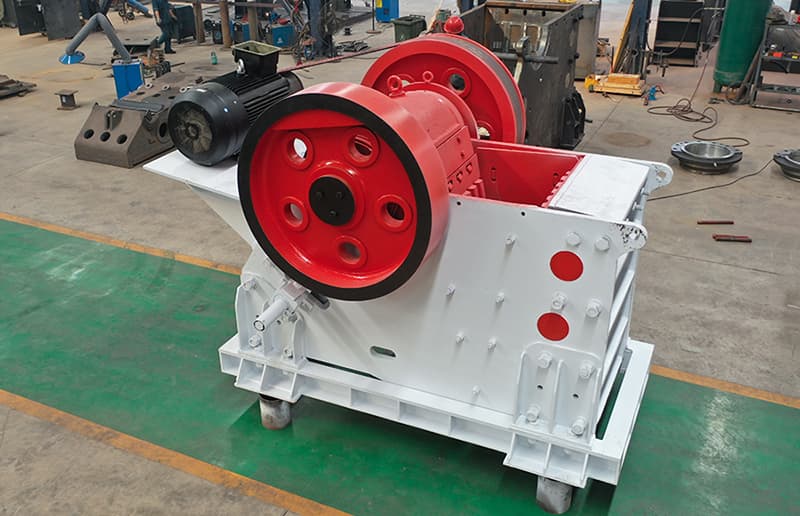

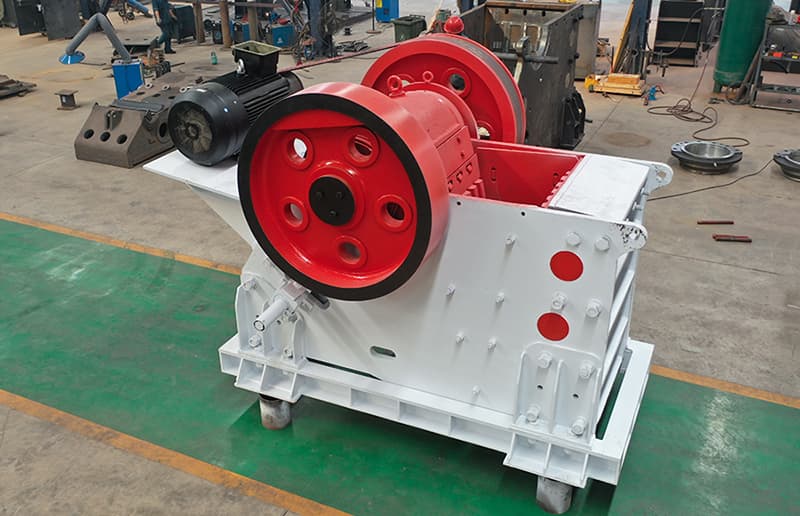

PEV jaw crusher is renowned in the mining, construction, and aggregate industries for its robust structure, high crushing efficiency, and strong adaptability to various raw materials.

As a versatile crushing equipment, it plays a pivotal role in primary crushing stages, handling a wide range of materials with different hardness, viscosity, and particle sizes.

Whether you’re processing natural ores, construction waste, or industrial by-products, the PEV jaw crusher delivers reliable performance that meets diverse production needs. Below is a detailed breakdown of the key materials it excels at processing.

1. Natural Stone Materials: The Core Application Scope

Natural stones are the most common materials processed by PEV jaw crushers. This is largely due to the equipment’s excellent crushing ratio and outstanding wear resistance.

It can efficiently handle both soft and hard natural stones, making it an indispensable piece of equipment in quarries and mining sites worldwide.

1.1 Soft to Medium-Hard Natural Stones

Materials with a Mohs hardness between 1 and 5 fall into the soft to medium-hard category. Typical examples include limestone, calcite, gypsum, and marble.

These materials are widely distributed and in high demand in the construction industry, used for making cement, aggregates, and decorative materials. The PEV jaw crusher’s optimized crushing cavity design ensures smooth feeding and uniform crushing of these stones.

For instance, limestone—with its low hardness and brittle texture—can be crushed by the

PEV jaw crusher into 5-50mm particles in one pass. It boasts a production capacity of up to 1,000 tons per hour, significantly boosting quarry operational efficiency.

1.2 Hard and Ultra-Hard Natural Stones

For materials with a Mohs hardness above 6—such as granite, basalt, quartzite, and diabase—the PEV jaw crusher demonstrates exceptional durability.

These stones are dense and wear-resistant, often used in high-strength construction projects like highway pavements and bridge foundations. To tackle such tough materials, the PEV jaw crusher is equipped with high-strength manganese steel jaw plates and a heavy-duty eccentric shaft, enhancing impact resistance and crushing force.

When processing granite, for example, the equipment can withstand high friction and impact, reducing jaw plate wear and ensuring stable long-term operation. This makes it a preferred choice for hard stone crushing projects.

2. Construction and Demolition Waste: A Sustainable Solution

With the global focus on environmental protection and resource recycling, processing construction and demolition (C&D) waste has become a key application area for the PEV jaw crusher.

Common C&D waste includes concrete blocks, brick fragments, and reinforced concrete—all rich in recyclable components. The PEV jaw crusher can effectively crush these materials into recycled aggregates for reuse in new construction projects.

The PEV jaw crusher’s adjustable discharge port allows it to produce recycled aggregates of different specifications, ranging from fine sand to coarse gravel.

When processing concrete waste, the equipment can separate concrete from reinforcing steel (with subsequent magnetic separation), ensuring the purity of the recycled aggregate. This not only reduces landfill pressure but also lowers demand for natural aggregates, contributing to sustainable development.

In urban renewal projects across Southeast Asia and Europe, PEV jaw crushers have become core equipment for C&D waste recycling.

3. Ores and Mineral Materials: Supporting Mining Operations

In the mining industry, the PEV jaw crusher is widely used for the primary crushing of various ores. It provides high-quality crushed materials for subsequent beneficiation processes.

Common processed ores include iron ore, copper ore, gold ore, bauxite, and coal, among others.

Different ores have unique properties. For example, coal is brittle and prone to powdering, while iron ore is dense and hard. The PEV jaw crusher’s flexible design allows parameter adjustment to match specific ore characteristics.

For coal crushing, the equipment uses a larger discharge port and lower crushing force to avoid excessive powdering, ensuring coal product quality. For iron ore, it adopts high-wear components and a strong crushing structure to break down hard ore blocks into uniform particles.

This facilitates subsequent magnetic separation and smelting, making the PEV jaw crusher a versatile tool in mining operations.

4. Industrial By-Products and Special Materials

Beyond the above categories, the PEV jaw crusher can process a variety of industrial by-products and special materials. This expands its application scope to industries like metallurgy, chemical engineering, and ceramics.

Here are some typical examples:

Metallurgical Slag: Blast furnace slag and steel slag, by-products of the steel industry, can be crushed by the PEV jaw crusher into aggregates for road construction or cement admixtures, realizing resource reuse.

Chemical Raw Materials: Materials like gypsum powder and potassium feldspar, used in the chemical and ceramic industries, require uniform particle sizes. The PEV jaw crusher’s precise crushing control ensures consistent product quality.

Glass and Ceramic Waste: Recycled glass and ceramic waste can be crushed by the PEV jaw crusher into fine particles for making new glass products or ceramic tiles, promoting circular economy.

Why the PEV Jaw Crusher Stands Out in Material Processing?

The PEV jaw crusher’s wide material adaptability stems from its advanced design and high-quality components. These key features work together to enhance its performance across different materials:

Robust Structure: A heavy-duty steel frame and reinforced crushing cavity resist impact and vibration, suitable for hard materials.

Wear-Resistant Components: Manganese steel jaw plates and alloy bearings have a long service life, reducing maintenance costs for abrasive materials.

Adjustable Discharge Port: Flexible adjustment of product particle size meets diverse application requirements for different materials.

High Crushing Efficiency: An optimized eccentric shaft design and large feeding port improve processing capacity, saving time and energy.

Choose the Right PEV Jaw Crusher for Your Material Needs

Whether you’re processing soft limestone, hard granite, recycled concrete, or valuable ores, the PEV jaw crusher offers a tailored solution.

To maximize performance, it’s essential to select the appropriate model and configuration. This depends on factors like material hardness, moisture content, and desired output specifications.

Reputable manufacturers can provide professional guidance—from material testing to equipment customization—ensuring the PEV jaw crusher fully meets your production demands.