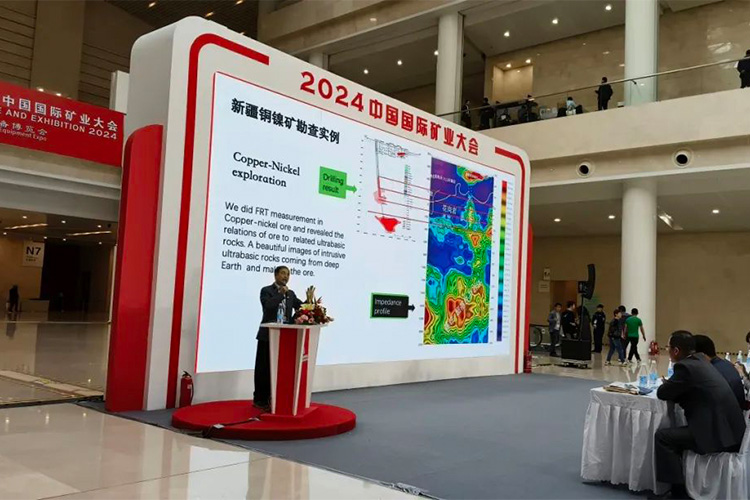

From October 15 to 18, 2024, the four-day China International Mining Conference came to a successful conclusion. This conference brought together 4,500 representatives from 41 countries and regions, with a total of nearly 10,000 participants and visitors. This conference has many highlights, including an opening ceremony, theme forums, high-level forums, special forums and special promotion meetings, totaling 38 events, covering everything from mining exploration to high-tech applications.

At the exhibition, Xingaonai Group fully demonstrated the group's latest achievements in the research and development of mining crushing equipment, including a series of high-efficiency, energy-saving, and intelligently controlled crushing equipment and mineral processing equipment. From raw material procurement to finished product delivery, each process is subject to strict quality control. Our crushing equipment has won high attention and praise from on-site audiences and industry insiders for its excellent durability and stability.

In the booth, Xingaonai Group demonstrated the group's technical strength and R&D achievements through various forms such as videos. Provide a full range of customized services from demand analysis, equipment selection to installation and commissioning, and after-sales service. We will tailor the most suitable crushing equipment solutions according to your specific needs to ensure the efficient operation of the project. At the same time, the group's professional team also conducted in-depth exchanges and negotiations with visitors from all over the world to jointly explore new opportunities and challenges in the development of the mining industry. With its outstanding products and technical strength, Xingaonai Group has won wide acclaim in the industry. As a leading enterprise in the field of mining crushing equipment, Xingaonai Group has always been committed to technological innovation and quality improvement, providing efficient, energy-saving and environmentally friendly solutions for global mining customers.

With the successful conclusion of the exhibition, Xingaonai Group not only gained valuable industry experience and cooperation opportunities, but also deeply felt the vigorous development and huge potential of the global mining industry.

This exhibition not only enhanced the visibility and influence of Xingaonai Group, but also provided a new opportunity for the group to cooperate with global mining companies. Xingaonai Group will continue to uphold the concept of "innovation, efficiency, energy saving and environmental protection" to provide global mining customers with better products and services.

Xingaonai Group will continue to actively participate in various exhibitions at home and abroad, and work hand in hand with global mining colleagues to jointly promote the prosperity and development of the mining industry. At the same time, the group will also actively respond to the green development trend of the global mining industry and strive to provide customers with more green and sustainable mining solutions.