Gyratory crushers represent one of the most critical investments in the mineral processing and aggregate production industries. Designed for extreme-duty applications, these massive machines serve as the first line of size reduction in high-tonnage operations, combining brute force with precision engineering to process some of the hardest materials on earth.

1. Structural Design and Working Principle

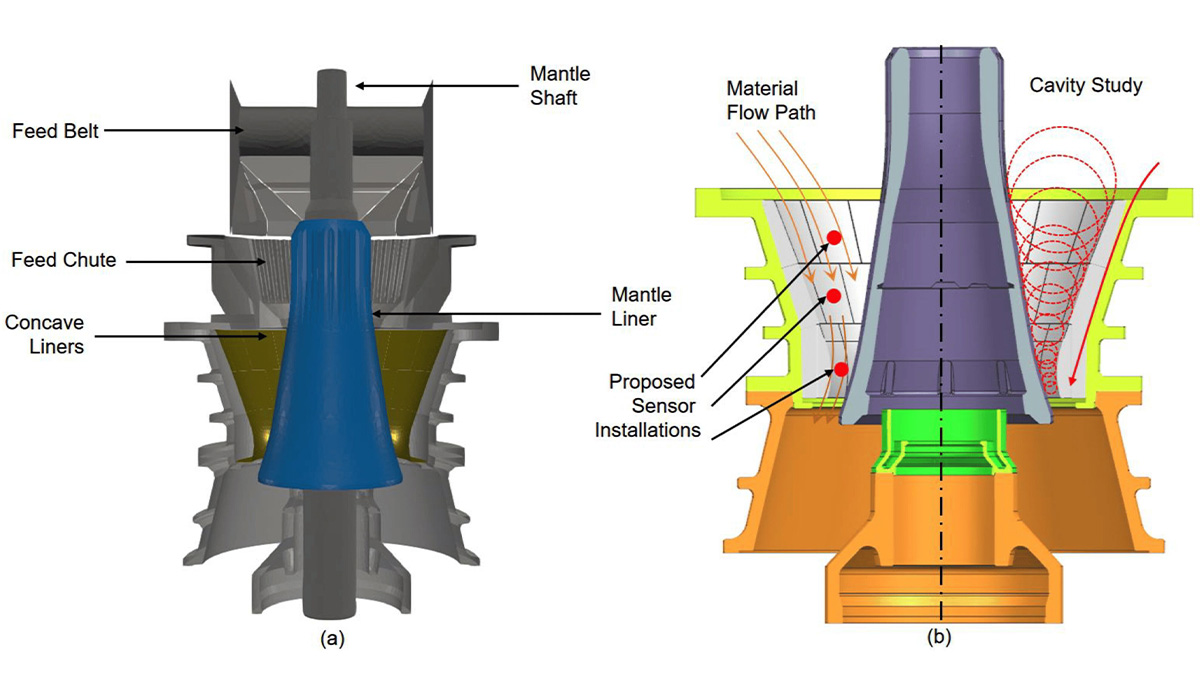

At the heart of a gyratory crusher is a solid cast-steel frame housing an eccentrically mounted main shaft. A crushing head (mantle) is attached to this shaft, which gyrates within a stationary concave hopper. The eccentric motion causes the mantle to alternately approach and recede from the concave, generating compressive forces that fracture the material. This mechanism allows continuous feed operation without the cyclical interruptions seen in jaw crushers, resulting in higher throughput and more uniform product sizing. The entire assembly is supported by a robust hydraulic system that enables adjustment of the crusher setting and provides protection against tramp iron and uncrushable objects.

Gyratory crushers deliver a compelling array of operational benefits that justify their prominence in heavy industrial settings:

2. Key Advantages and Performance Benefits

Exceptional Capacity: Capable of processing over 10,000 metric tons per hour in the largest models, making them ideal for mega-mining projects.

Superior Efficiency: The continuous crushing process and deep crushing chamber design lead to higher reduction ratios and lower energy consumption per ton compared to alternative primary crushers.

Enhanced Reliability: Built with heavy-duty components and designed for decades of service, these crushers offer remarkable availability and longevity, even in the most abrasive environments.

Advanced Automation Readiness: Modern gyratory crushers are equipped with sensors and control systems that allow real-time monitoring of performance parameters, facilitating predictive maintenance and optimizing operational efficiency.

3. Industrial Applications and Use Cases

These machines are the preferred choice in a variety of demanding sectors:

Metal Mining: extensively used in copper, gold, and iron ore operations to handle run-of-mine material directly from the pit.

Aggregate Production: deployed in large-scale construction aggregate plants where high volumes of basalt, granite, or limestone must be processed.

Cement Manufacturing: utilized for primary crushing of limestone and other cement raw materials, often integrated with inline pre-homogenization systems.

Major Infrastructure Projects: critical in dam construction, road base preparation, and railway ballast production where consistent product quality is mandatory.

4. Technological Innovations and Modern Features

The evolution of gyratory crusher technology has introduced several groundbreaking features:

Intelligent Hydraulic Control: Automated adjustment systems maintain optimal crusher performance and protect the machine from damage due to overloads or uncrushables.

Advanced Liner Materials: Innovative alloy compositions and design profiles extend service life and reduce downtime for maintenance.

Integrated Monitoring Systems: Vibration analysis, temperature sensing, and power draw monitoring provide early warning of potential problems, enabling planned interventions.

Remote Operation Capabilities: Many newer models can be fully controlled and adjusted from a centralized control room, enhancing safety and operational flexibility.

5. Selection Criteria and Configuration Considerations

Selecting the appropriate gyratory crusher requires careful evaluation of multiple factors:

Feed Material Characteristics: including compressive strength, abrasiveness, moisture content, and maximum feed size.

Production Requirements: desired throughput, product size distribution, and downstream process needs.

Site-Specific Constraints: available space, foundation requirements, and environmental regulations.

Lifecycle Cost Analysis: evaluating not only initial capital investment but also long-term operating and maintenance expenses.

6. Operational Best Practices and Maintenance Strategies

Maximizing crusher performance and service life demands adherence to proven operational protocols:

Regular Liner Inspections: scheduled examinations of mantle and concave wear patterns to plan replacements proactively.

Lubrication System Maintenance: ensuring the integrity of the lubrication system is critical to preventing premature bearing failure.

Crusher Setting Optimization: periodic adjustments to maintain product quality while maximizing throughput.

Operator Training: comprehensive education programs to ensure personnel understand crusher capabilities and limitations.

7. Future Development Trends and Industry Directions

The future of gyratory crusher technology is being shaped by several powerful trends:

Digitalization and IIoT Integration: increasing connectivity and data analytics capabilities will enable fully autonomous operation and real-time performance optimization.

Sustainability Enhancements: development of more energy-efficient designs and systems to reduce the environmental footprint of crushing operations.

Hybrid Drive Systems: incorporation of energy recovery systems and alternative power sources to lower operating costs.

Modular and Scalable Designs: offering greater flexibility in plant layout and expansion possibilities.

8. Conclusion: The Strategic Role of Gyratory Crushers in Modern Industry

As global demand for minerals and construction materials continues to grow, gyratory crushers remain indispensable tools for achieving the production volumes required by modern society. Their evolution from simple mechanical breakers to sophisticated, connected industrial assets reflects the ongoing transformation of the extractive industries. For operations requiring reliable, high-capacity primary crushing, gyratory crushers continue to offer unmatched performance and value, serving as the foundational element upon which entire processing plants are built. The continued innovation in this field ensures that these massive machines will remain at the forefront of mineral processing technology for decades to come.