The output of gold ore investment is gold, which is loved by consumers and well-known by investors around the world. Against the backdrop of China, Russia and other countries collectively increasing their gold reserves, global gold consumption and investment demand are growing, which provides sales guarantee for gold mine output. Whether investing in gold jewelry or investment products, there is huge market potential. New Gaonai Group provides you with a full set of gold ore crushing and processing production equipment, and provides you with detailed technical support.

Crushing and screening

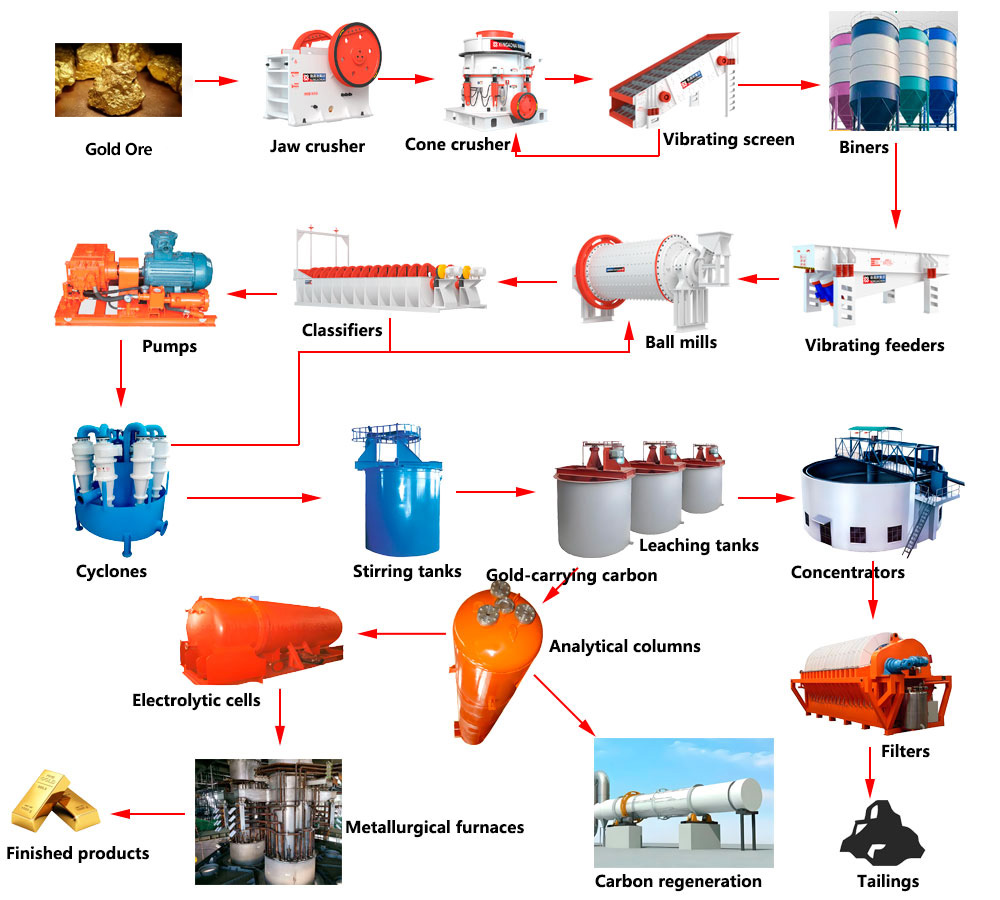

Large pieces of gold ore are evenly fed into a jaw crusher or a mobile crushing station for coarse crushing by a vibrating feeder through a silo; the coarsely crushed gold ore is screened by a vibrating screen and sent to a single-cylinder hydraulic cone crusher by a belt conveyor for medium crushing; the medium-crushed gold ore material is sent to a multi-cylinder hydraulic cone crusher for fine crushing.

Grinding

The 0-12 mm gold powder screened by the vibrating screen is evenly fed into a grinding mill for grinding, and screened by a spiral classifier, and those that do not meet the requirements are sent to a grinding mill for further grinding.

Ore dressing

Due to the different types and properties of gold ores, different ore dressing methods are used in the ore dressing process, but gravity separation, flotation, mercury mixing, cyanidation, and today's resin slurry method, carbon slurry adsorption method, and heap leaching method are generally used to extract gold. For some types of ores, a combined gold extraction process is often used.