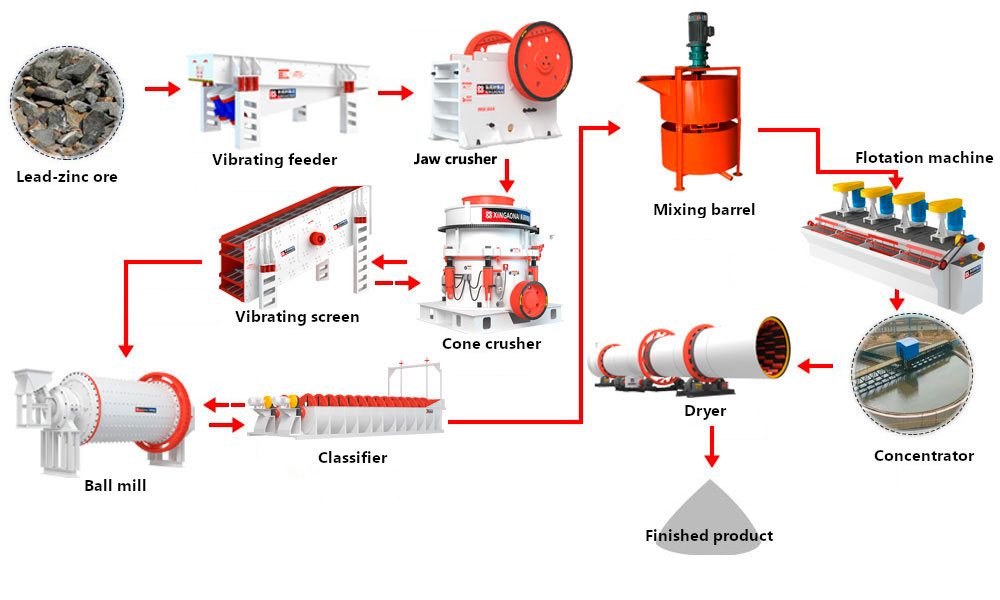

Lead-zinc ore processing and production technology mainly includes three processes: crushing, grinding and beneficiation. In the crushing process, three-stage closed-circuit crushing is a modern crushing method suitable for high-hardness lead-zinc ores, which can complete the work of ore crushing and partial dissociation, thereby improving the efficiency of subsequent grinding; in the grinding process, two-stage one-closed grinding can make the lead-zinc ore more fully ground; in the beneficiation process, the more successful new process that has emerged in recent years is mainly represented by the mixed flotation process.

Crushing and screening

Large pieces of lead-zinc ore are evenly fed into a jaw crusher or a mobile crushing station for coarse crushing by a vibrating feeder through a silo; the coarsely crushed lead-zinc ore is screened by a vibrating screen and then sent to a single-cylinder hydraulic cone crusher by a belt conveyor for medium crushing; the medium-crushed lead-zinc ore material is sent to a multi-cylinder hydraulic cone crusher for fine crushing.

Grinding

The 0-12 mm lead-zinc ore screened by the vibrating screen is evenly fed into a grinding mill for grinding, and screened by a spiral classifier, and those that do not meet the requirements are sent to a grinding mill for further grinding.

Ore dressing

The powder ore that meets the requirements of ore dressing is sent to a magnetic separator for strong magnetic separation to remove impurities, and the obtained ore powder is sent to a dryer for drying to obtain concentrate.