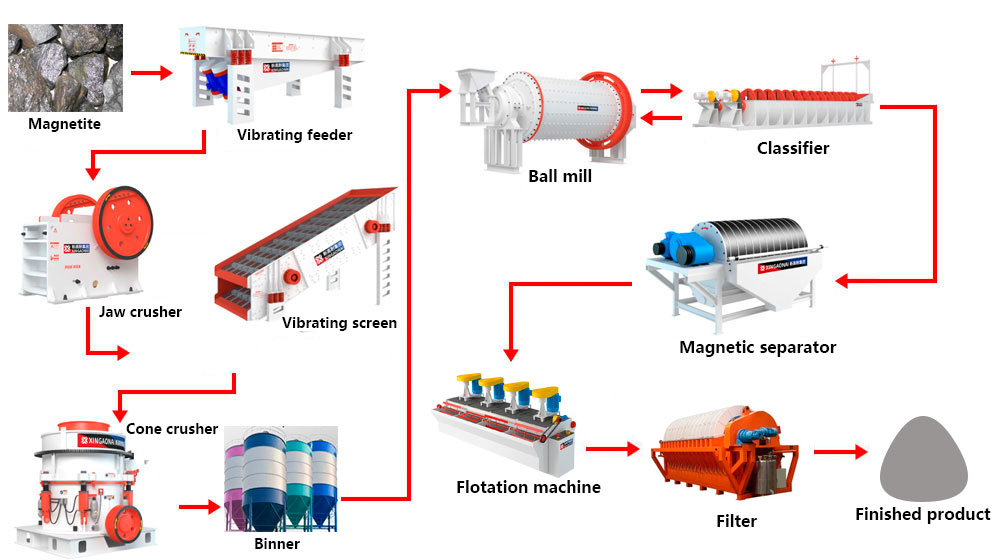

Process method

According to the magnetic strength of the ore, the ore dressing process method suitable for its properties is selected. The magnetic separation process is used as the main process method, and the combination of gravity separation, flotation, roasting and magnetic separation is a combined process method. The ore separation and separation has a basis.

Strong magnetic iron ore dressing process

It is mainly used to select low-grade magnetite. Because the ore has strong magnetism and is easy to grind and select, the current stage grinding is mostly used for coarse-grained magnetite, and the multi-stage grinding process is used for the opposite.

Weak magnetic iron ore dressing process

Weak magnetic minerals can be selected by the selection method of strong magnetic minerals after magnetization roasting.

Fine grinding

In the two-stage grinding, stage selection, and single weak magnetic separation process, the fine screen re-grinding and re-selection process is added, which can separate the fine-grained minerals that have achieved monomer dissociation in time, reduce the occurrence of over-grinding, and improve the processing capacity.