Graphite is one of the crystalline minerals of carbon element, with excellent properties such as lubricity, chemical stability, high temperature resistance, electrical conductivity, special thermal conductivity, plasticity, coating, etc. Its application field is very wide. It plays an important role in the development of modern science and technology and industry such as metallurgical industry, foundry industry, electrical industry, mechanical industry, chemical industry, nuclear industry, aerospace industry, etc.

Multi-stage grinding and multi-stage flotation

In order to protect graphite flakes from damage, a multi-stage grinding process is often used. After multiple re-grinding and re-selection, the concentrate quality meets the requirements.

Combined process of gravity separation and flotation

For graphite ores with heavy minerals, gravity separation and flotation are combined for separation, that is, heavy minerals are first separated by gravity separation, and then the gravity separation tailings are treated by flotation.

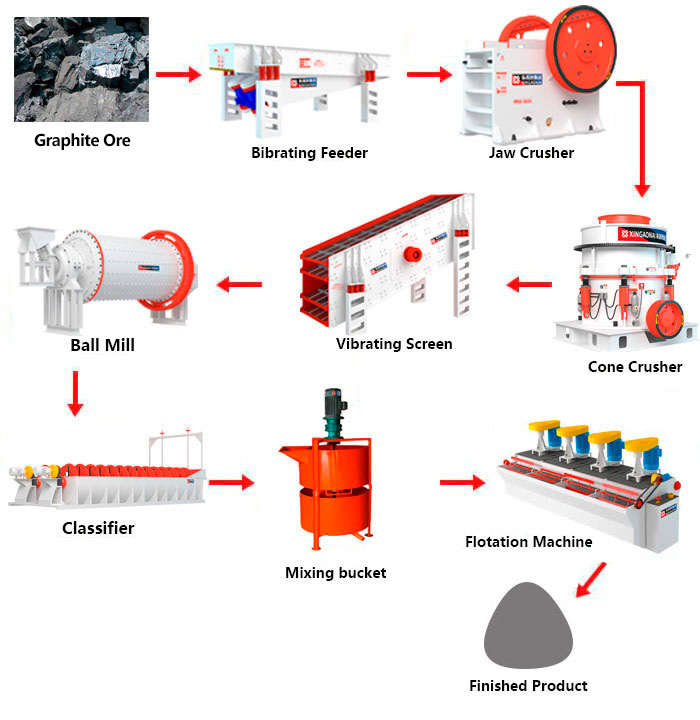

Graphite ore dressing equipment

Generally, jaw crushers are used for coarse crushing of crystalline and amorphous graphite ores, and cone crushers or hammer crushers are used for medium and fine crushing; wet ball mills and grate ball mills are used for grinding; hydrocyclones or belt filters are commonly used for graphite ore dressing and dehydration.