Feldspar is the most important rock-forming mineral in surface rocks. Feldspar is the general name for feldspar family minerals. It is a common type of aluminum silicate rock-forming mineral containing calcium, sodium and potassium. Feldspar is a crystallization of magma in intrusive or eruptive igneous rocks, forming veins; it can also exist in many metamorphic rocks. Rocks formed almost entirely by calcium plagioclase are called anorthite. Feldspar is also found in many sedimentary rocks. The crust of the moon is also composed of feldspar. Feldspar rich in potassium or sodium is mainly used in the ceramic industry, glass industry and enamel industry. Feldspar containing rare elements such as rubidium and cesium can be used as mineral raw materials for extracting these elements. Feldspar with beautiful colors can be used as decorative stones and semi-precious gems.

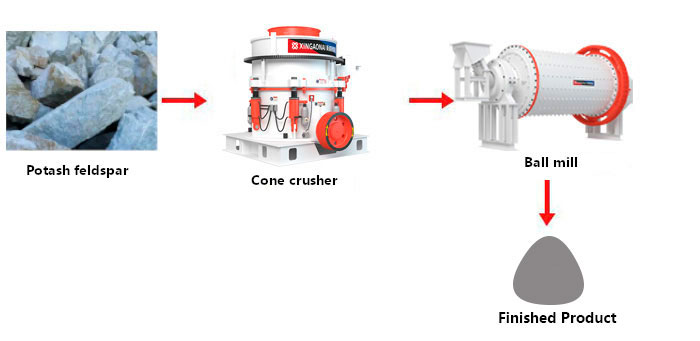

Crushing and screening stage

According to the different bulk particle sizes of the raw ore, from a simple one-stage crushing process to a three-stage crushing process, the block ore is coarsely crushed and then screened. The qualified ore in the crushing stage enters the grinding operation, and the ore on the screen is returned to the fine crushing, ensuring the qualification of the ore particle size entering the next stage.

Grinding and grading stage

The qualified products in the crushing stage enter the ball mill for grinding, the discharge of the ball mill enters the grading equipment for grading, the sand settling of the grading equipment returns to the ball mill for re-grinding, and the overflow of the grading equipment is the qualified product in the grinding stage.

Desludging stage

The qualified ground material is sent to the desludging bucket for desludging.

Sorting stage

Magnetic separation stage: After desludging, the ore enters the two-stage magnetic separation operation of weak magnetic + strong magnetic to remove the magnetic substances in the ore.

Flotation stage: In order to remove impurities such as iron, calcium and mica that may exist in the magnetic concentrate, separate excess quartz in the ore and improve the grade of the concentrate, the magnetic concentrate will be flotated to remove impurities and purify.