Basalt is the best material used for repairing roads, railways, and airport runways. It has the advantages of strong compression resistance, low crushing value, strong corrosion resistance, and asphalt adhesion. Basalt has the advantages of wear resistance, low draft, poor electrical conductivity, strong compression resistance, low crushing value, strong corrosion resistance, and asphalt adhesion. It is internationally recognized and is the best cornerstone for the development of railway and road transportation.

First process

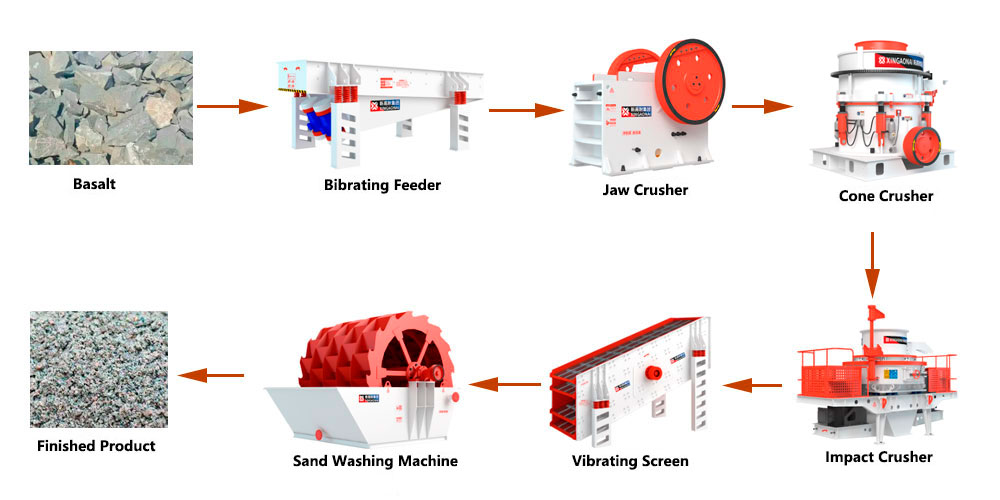

The large basalt blocks are fed evenly by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushing. The coarsely crushed materials are screened by the vibrating screen and then transported by the belt conveyor to the impact crusher or cone crusher for medium and fine crushing.

Second process

After medium and fine crushing, the basalt transported to the impact crusher/cone crusher is screened by the circular vibrating screen, and the larger particles are returned to the impact crusher/cone crusher for further crushing.

Third process

The crushed basalt is sent to the sand making machine for further crushing and shaping. If clean basalt is required, it can be sent to the sand washing machine for cleaning.