Granite is a high-quality building stone with uniform structure, hard texture, beautiful color and durability. Granite can be used from roof to floor in construction. If it is crushed, it can be made into cement or rock filling dam. Granite is not easy to weather, has beautiful color, and its appearance can be maintained for more than a hundred years. In addition to being used as an ideal building decoration and hall floor, it is also an ideal material for outdoor sculpture. Because granite is rarer than ceramics or other man-made materials, laying granite floors can greatly increase the value of large properties. Natural granite countertops have unique temperature resistance and are ideal for processing various types of panels.

First process

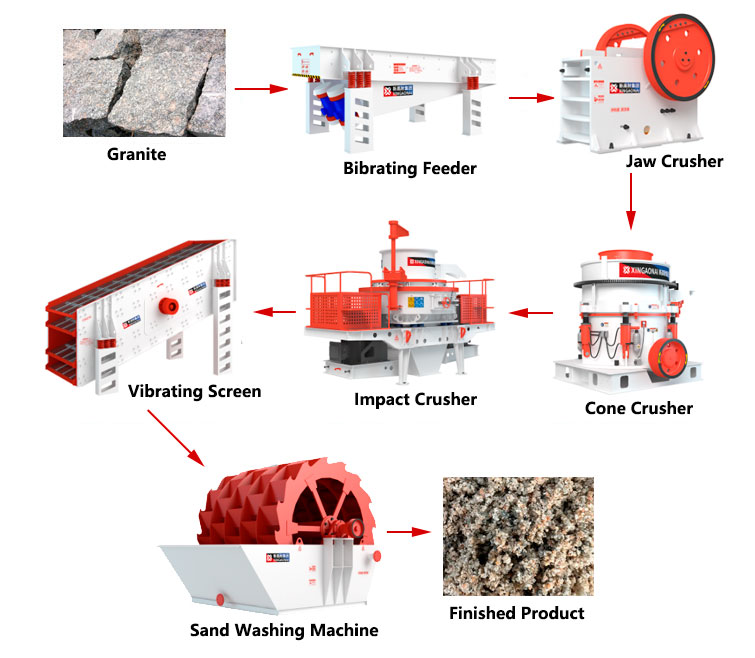

The large granite blocks are fed evenly by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushing. The coarsely crushed materials are screened by the vibrating screen and then transported by the belt conveyor to the impact crusher or cone crusher for medium and fine crushing.

Second process

After medium and fine crushing, the granite transported to the impact crusher/cone crusher is screened by the circular vibrating screen, and the larger particles are returned to the impact crusher/cone crusher for further crushing.

Third process

The crushed granite is sent to the sand making machine for further crushing and shaping. If clean granite is required, it can be sent to the sand washing machine for cleaning.