Hematite is the main mineral form of iron oxide. It is heavy and hard. Iron is mainly smelted from hematite. Hematite contains up to 70% iron and can be produced in large quantities, making it the most important iron ore. Hematite's name comes from its dark red color. Hematite deposits are widely distributed and can be formed in many situations, but the most important hematite deposits are sedimentary. Hematite is often produced together with magnetite. In addition to iron smelting, powdered hematite is also used as a red pigment and abrasive.

Stage grinding

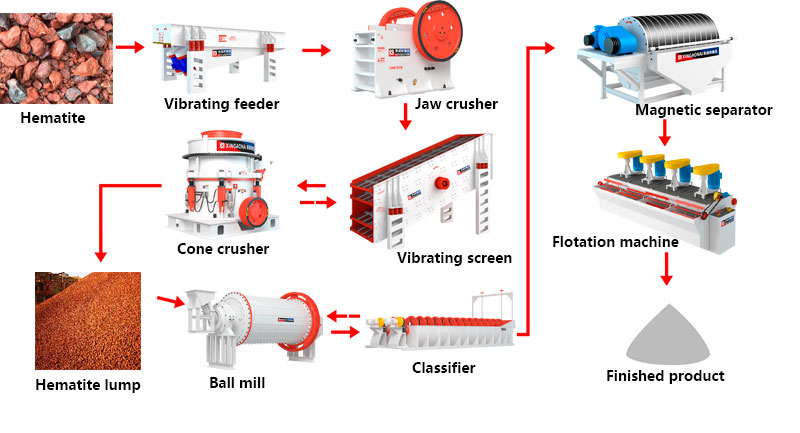

The first stage of grinding and classification uses a ball mill and a cyclone to form a closed-circuit grinding, which can ensure both classification efficiency and classification particle size; at the same time, some qualified concentrates can be sorted in advance. In addition, part of the low-grade tailings can be discarded through the high-gradient magnetic separator, which can not only reduce the amount of regrinding of medium ore, but also avoid over-grinding and reduce metal loss.

Magnetic separation-flotation combined process

The magnetic separation operation timely separates qualified coarse-grained concentrates and tailings, which conforms to the principle of early harvest and early abandonment, and reduces the flotation operation volume and cost.

Flotation process

The strong magnetic process can recover fine-grained iron minerals, which can play the dual roles of desliming and tailing, creating better conditions for flotation operations.

Reverse flotation process

The chemical system of the reverse flotation process is simple, which can significantly reduce the entry of organic matter such as flotation chemicals into the slurry and reduce its adverse impact on the flotation process.